Professional Documents

Culture Documents

Minor

Minor

Uploaded by

sunilsubhranshu28Copyright:

Available Formats

You might also like

- Combined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationDocument9 pagesCombined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationAndrew MwambaNo ratings yet

- Vedant Development 1Document1 pageVedant Development 1NIK GAMINGNo ratings yet

- Cost AnalysisDocument13 pagesCost Analysisnaveen yadavNo ratings yet

- Starworth 1Document1 pageStarworth 1KIRAN GNo ratings yet

- HPS Sumur Bor1Document72 pagesHPS Sumur Bor1Harianto PnsNo ratings yet

- Concrete Mix Design C 25 For KamoaDocument9 pagesConcrete Mix Design C 25 For KamoaMitendra Kumar ChauhanNo ratings yet

- Concrete Moisture Correction SheetDocument7 pagesConcrete Moisture Correction SheetAmit MaityNo ratings yet

- Thar Coal Utilization 30 June 2022 - 08042024 - FinalDocument4 pagesThar Coal Utilization 30 June 2022 - 08042024 - Finalmaaas81No ratings yet

- Vedant Propertis Royal 1Document1 pageVedant Propertis Royal 1NIK GAMINGNo ratings yet

- Contractor Consultant: Republic of Kenya Ministry of Roads and Public WorksDocument4 pagesContractor Consultant: Republic of Kenya Ministry of Roads and Public WorksGikonyoNo ratings yet

- 01-Concrete Mix + MED CertDocument21 pages01-Concrete Mix + MED CertAnwar SadathNo ratings yet

- Knowles Electronics Phils. Cebu Light Industrial Park, Lapu-Lapu CityDocument2 pagesKnowles Electronics Phils. Cebu Light Industrial Park, Lapu-Lapu CityEJ TabamoNo ratings yet

- Nh-44a Work Program Upto 31.12.2019 For Rce-IIDocument1 pageNh-44a Work Program Upto 31.12.2019 For Rce-IIMAROTHU MOHAN MANOJNo ratings yet

- Design Mix Summary: For Contractor (KOYA & CC) For Authority Engineer Name Name Designation Designation Date DateDocument4 pagesDesign Mix Summary: For Contractor (KOYA & CC) For Authority Engineer Name Name Designation Designation Date DateCar ThickNo ratings yet

- Concrete Mix Design C 30 For KamoaDocument9 pagesConcrete Mix Design C 30 For Kamoamitendra singhNo ratings yet

- Overview On The Indian Cement Sector and Its Changing Coal RequirementsDocument28 pagesOverview On The Indian Cement Sector and Its Changing Coal RequirementsNEELNo ratings yet

- PF-1 Bill Mar 2008Document17 pagesPF-1 Bill Mar 2008api-3823524No ratings yet

- Partial Replacement of Cement With Waste Paper Sludge AshDocument11 pagesPartial Replacement of Cement With Waste Paper Sludge AshIJRASETPublicationsNo ratings yet

- Sno Description Unit Rate Rs. Amount RS.: Data 2020-21 QuantityDocument24 pagesSno Description Unit Rate Rs. Amount RS.: Data 2020-21 QuantitysagarNo ratings yet

- Meltio-Nickel-625 Material Datasheet PDFDocument2 pagesMeltio-Nickel-625 Material Datasheet PDFJakNo ratings yet

- Cement Replace Wood AshDocument7 pagesCement Replace Wood AshM JOSEPH DAVID SELVANNo ratings yet

- PQC Mix Design 01 (Camp 01) 1Document120 pagesPQC Mix Design 01 (Camp 01) 1Imran Khan67% (3)

- By HMP (Analysis)Document7 pagesBy HMP (Analysis)Prashant VermaNo ratings yet

- BOQ Sumur Bor2Document72 pagesBOQ Sumur Bor2Harianto PnsNo ratings yet

- Sow System MDPDocument1 pageSow System MDPpernando silalahiNo ratings yet

- 3 GVP WeDocument22 pages3 GVP Wemurlikrishna3014887No ratings yet

- Netc DBMDocument34 pagesNetc DBMMorya RonakNo ratings yet

- Partial Replacement of Sand by Granite Powder in Concrete: Narmatha.M Vishali.G Noveena.SDocument5 pagesPartial Replacement of Sand by Granite Powder in Concrete: Narmatha.M Vishali.G Noveena.Sshivanand hippargaNo ratings yet

- Burnt Bricks Wall With RCC Slab (6) Classroom School Bill of Quantity (BOQ)Document16 pagesBurnt Bricks Wall With RCC Slab (6) Classroom School Bill of Quantity (BOQ)wafiullah sayedNo ratings yet

- Specification For Precast ChamberDocument6 pagesSpecification For Precast ChamberTai ChoonNo ratings yet

- Fencing To Cremitorium4Document3 pagesFencing To Cremitorium4K KARTHIKNo ratings yet

- BA SummaryDocument7 pagesBA SummaryPadmalavMahatoNo ratings yet

- ARCH 381 ThermodynamicsDocument11 pagesARCH 381 ThermodynamicsElanur MayaNo ratings yet

- 01 BOQ and Rate Analysis - Kolar-Kanhan Barrage 11122019.Document2 pages01 BOQ and Rate Analysis - Kolar-Kanhan Barrage 11122019.Prashant HuddarNo ratings yet

- 450mm Dia Hume Pipes CostDocument4 pages450mm Dia Hume Pipes Costnag00naNo ratings yet

- Rakesh R S Saudi Tabreed District CoolingDocument19 pagesRakesh R S Saudi Tabreed District CoolingAbdul Aziz Abdul Razak KedahNo ratings yet

- Bill of Quantity (Boq) (8) Class Room (Brick Masonry+ RCC Slab) (3mhight)Document26 pagesBill of Quantity (Boq) (8) Class Room (Brick Masonry+ RCC Slab) (3mhight)wafiullah sayedNo ratings yet

- Biweekly ProgressDocument1 pageBiweekly ProgressIkhsan BakhrullohNo ratings yet

- 1.summary of Concrete Mix DesignsDocument2 pages1.summary of Concrete Mix DesignsGanesh Kumar TulabandulaNo ratings yet

- Culvert Final Version in EnglishDocument12 pagesCulvert Final Version in Englishdeven gcNo ratings yet

- Toromocho Jan2017 Competent Persons ReportDocument147 pagesToromocho Jan2017 Competent Persons Reportmaría joséNo ratings yet

- Brick Masonry Rate AnalysisDocument2 pagesBrick Masonry Rate AnalysisersrcivilNo ratings yet

- Lab 1Document8 pagesLab 1Maica Joyce C. MonsalesNo ratings yet

- Changeover 1.1Document4 pagesChangeover 1.119512113No ratings yet

- Site Grading, Subgrade Excavate (Cut & Fill) Excavation (Cut) & Backfilling Compacted To 90% MDDDocument13 pagesSite Grading, Subgrade Excavate (Cut & Fill) Excavation (Cut) & Backfilling Compacted To 90% MDDEdgar QuinonesNo ratings yet

- M20 Kerb - Mix Design Calculation: Volume of Cementicious Materials+Water+AdmixtureDocument1 pageM20 Kerb - Mix Design Calculation: Volume of Cementicious Materials+Water+Admixturevdbshamsabad labNo ratings yet

- K-100 7hariDocument1 pageK-100 7harideasyaja1212No ratings yet

- Bill SampleDocument2 pagesBill SampleSayyidMahmoodThangalKVNo ratings yet

- DPR-BGR17 6.8.23 - Bridge FabricationDocument1 pageDPR-BGR17 6.8.23 - Bridge FabricationSivamurugan SivanayagamNo ratings yet

- WP Contentuploads202311EMSTEEL Investor Presentation 11.2023 v1.PDF 2Document40 pagesWP Contentuploads202311EMSTEEL Investor Presentation 11.2023 v1.PDF 2g00089664No ratings yet

- En Materi Pe Gems 22 Nov 2022Document34 pagesEn Materi Pe Gems 22 Nov 2022Herman TaniwanNo ratings yet

- S/No. Item A/U Qty Density WT of Mix in MT WT of Bitumen in MT WT of Agg in MTDocument5 pagesS/No. Item A/U Qty Density WT of Mix in MT WT of Bitumen in MT WT of Agg in MTM.E. TECHNOLOGYNo ratings yet

- Summary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCDocument3 pagesSummary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCmeerut nazibabad projectNo ratings yet

- Urban: Pay Date Cac No. Amount Paid Punch DateDocument1 pageUrban: Pay Date Cac No. Amount Paid Punch DateakhileshNo ratings yet

- Q3 Meeting SMCL HR.Document5 pagesQ3 Meeting SMCL HR.Santosh KumarNo ratings yet

- 2-Detailed Cost EstimateDocument62 pages2-Detailed Cost Estimateanuj khadkaNo ratings yet

- Marshall Stability Test PDFDocument8 pagesMarshall Stability Test PDFAnonymous FO4sHLLONo ratings yet

- Partial Replacement of Sand With Sawdust in Concrete ProductionDocument7 pagesPartial Replacement of Sand With Sawdust in Concrete ProductionkimNo ratings yet

- ProdPlan 2017.R4.TVBzDocument54 pagesProdPlan 2017.R4.TVBzbinsarNo ratings yet

- MetallographyDocument7 pagesMetallographyMehmet Ali CanNo ratings yet

- CHEN2000 FinalDocument10 pagesCHEN2000 FinalKHÁNH VÂN DIỆPNo ratings yet

- N H S Office Complex: 3100 S. Figueroa Street Los Angeles, Ca 90007Document1 pageN H S Office Complex: 3100 S. Figueroa Street Los Angeles, Ca 90007Rafael SathlerNo ratings yet

- Chemistry 2: Modified Strategic Intervention MaterialsDocument9 pagesChemistry 2: Modified Strategic Intervention MaterialsJenny Mae LopezNo ratings yet

- PRC 140625040720 Phpapp02Document12 pagesPRC 140625040720 Phpapp02besartNo ratings yet

- SDS 80 Fat Unsalted Butter Lactic AcidDocument8 pagesSDS 80 Fat Unsalted Butter Lactic Acidfiyan maulanaNo ratings yet

- Iron Metallurgy by Nwaogbe JohnDocument26 pagesIron Metallurgy by Nwaogbe JohnDavid UdohNo ratings yet

- Precast EnvelopeDocument70 pagesPrecast Envelopesdutta2591No ratings yet

- Tile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncDocument4 pagesTile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncRoland CepedaNo ratings yet

- Rockwool 159Document37 pagesRockwool 159ashish2783No ratings yet

- Colligative PropertiesDocument41 pagesColligative PropertiesJoshua SagunNo ratings yet

- BenedictDocument5 pagesBenedictMark Justin LealNo ratings yet

- 3D ConsolidationDocument25 pages3D ConsolidationHashir ChNo ratings yet

- Vacuum Coating of Plastic OpticsDocument15 pagesVacuum Coating of Plastic OpticsSasiKumar PetchiappanNo ratings yet

- Analysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Document2 pagesAnalysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Eustache NIJEJENo ratings yet

- Electron BeamDocument5 pagesElectron Beamrangaraobdl30198No ratings yet

- SuperkonduktorDocument18 pagesSuperkonduktorMuhammad Reihan IskandarNo ratings yet

- Welding Electrode ChartDocument2 pagesWelding Electrode ChartZaheed Manoo50% (2)

- Transport Phenomena III: Mass Transfer Chapter 28: Convective Mass TransferDocument23 pagesTransport Phenomena III: Mass Transfer Chapter 28: Convective Mass Transferنزار الدهاميNo ratings yet

- Chemical Effects of ElectricityDocument9 pagesChemical Effects of ElectricityJay Sunga VillanNo ratings yet

- Soil Properties and Soil MechanicsDocument7 pagesSoil Properties and Soil Mechanicsnixen99_gellaNo ratings yet

- Code Osff Practice RC 50022 Selection and Design of Pavements and SurfacingsDocument21 pagesCode Osff Practice RC 50022 Selection and Design of Pavements and Surfacingslosmi91No ratings yet

- NCMA Thermal Catalog of Concrete Masonry AssembliesDocument96 pagesNCMA Thermal Catalog of Concrete Masonry AssembliesestanilorenteNo ratings yet

- 1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgDocument13 pages1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgbanhrangNo ratings yet

- Sandvik Oilgas Hydraulic and Instrumentation Brochure S Tu278 EngDocument14 pagesSandvik Oilgas Hydraulic and Instrumentation Brochure S Tu278 EngDejan AntanasijevicNo ratings yet

- DESERT Solar CellsDocument2 pagesDESERT Solar CellsAndrew AtotuomahNo ratings yet

- Ms ProofDocument4 pagesMs Proofrizky efrinaldoNo ratings yet

- Minimum Pressurization TemperatureDocument4 pagesMinimum Pressurization TemperatureRonald MesinaNo ratings yet

- Notes On Applied GeologyDocument35 pagesNotes On Applied Geologyavula43No ratings yet

- FRP Unlimited: Connecting Professionals To The Value of Fibre Reinforced PlasticsDocument5 pagesFRP Unlimited: Connecting Professionals To The Value of Fibre Reinforced Plasticsargentino_ar01No ratings yet

Minor

Minor

Uploaded by

sunilsubhranshu28Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minor

Minor

Uploaded by

sunilsubhranshu28Copyright:

Available Formats

MINOR PROJECT PRESENTATION

ON

FABRICATION OF A FROTH FLOTATION UNIT FOR FINE AND ULTRAFINE

COAL BENEFICIATION OF TALCHER AREA

INDIRA GANDHI INSTITUTE OF TECHNOLOGY, SARANG

DEPARTMENT OF CHEMICAL ENGINEERING

Presented by: Under the guidance of

Dr. (Mrs.) Brahmotri Sahoo

Badal Kumar Sahoo Assistant Professor

Subhransu Sunil Barik Chemical engineering department

Bikash Kumar Sethi

Kalyan Kumar Mohanty

Ashis Kumar Jaipuri

Outlines of Presentation

Introduction

Literature Surveys

Objective of Work

Experimentation

Result and Discussion

Conclusion

Reference

Date: 21/12/2023 Minor Project Presentation Page No: 02

Introduction

Hey!! I’m Coal.

An organic rock

Origin of Coal

Drift Theory In-Situ Theory

Date: 21/12/2023 Minor Project Presentation Page No: 02

Introduction contd.

Coal

Lignite Sub-bituminous Bituminous Anthracite

Increasing rank of coal

Increasing moisture content

Increasing carbon content

Fig 1: Flowsheet of rank of coal

Date: 21/12/2023 Minor Project Presentation Page No: 02

Introduction contd.

Import Of Coal Sector Wise Off -take of Raw

Cocking coal imported(MT) Non-cocking coal imported(MT)

Coal in India During 2022-23

Import (MT)

2012- 2013- 2014- 2015- 2016- 2017- 2018- 2019- 2020- 2021- Power (Utility) Power (Captive) Steel

13 14 15 16 17 18 19 20 21 22 Cement Fertilizers Sponge Iron

Year Other basic-Metal Chemical Pulp & Paper

Textiles & Rayons Bricks Others

Date: 21/12/2023 Minor Project Presentation Page No: 02

Introduction contd.

Producti on of Raw Coal

1000.0 0.16

14.76%

893.1

900.0 0.14

800.0 778.2 0.12

728.7 730.9 716.1

700.0 657.9 675.4 0.1

639.2

609.2 8.67%

600.0 556.4 565.8 7.67% 7.89% 0.08

Prodution (MT)

Grpwth%

500.0 0.06

4.93%

400.0 0.04

2.92% 2.66%

300.0 1.68% 0.02

200.0 0.00% 0.30% 0

100.0 -2.02% -0.02

0.0 -0.04

2012-13 2013-14 2014-15 2015-16 2016-17 2017-18 2018-19 2019-20 2020-21 2021-22 2022-23

Year

Production (MT) Growth%

Date: 21/12/2023 Minor Project Presentation Page No: 02

Introduction contd.

Coal from mines Crushing

Screening

Course Size

(>12.5mm)

Separation Based on

Density

Medium Size

(12.mm-50µm)

Separation Based on Fine and ultrafine

Surface Tension Size (<50µm)

Date: 21/12/2023 Minor Project Presentation Page No: 02

Coal Beneficiation Methods

Physical Physio-Chemical Chemical

Bio-Processing

Methods Methods Methods

Gravity Separation Froth Flotation Acid Leaching

Magnetic Separation Oil Agglomeration Alkali Leaching

Electrostatic Separation Leaching with alkali

Followed by acid

Microwave Treatment

Fig 2: Flowsheets of Coal beneficiation methods

Date: 21/12/2023 Minor Project Presentation Page No: 02

Types of Coal washing Process:

Gravity Wet Process Jigs

Separation

Methods Landry Wilfley Rising

Washer Table Current

Density

Classifier

Separation

Dry Process

Methods

Coal Float and Jigs Tables

Washing sink

Process Methods

Surface

Separation

Methods

Oil agglomeration

Froth Flotation

Date: 21/12/2023 Minor Project Presentation Page No: 02

Literature Review

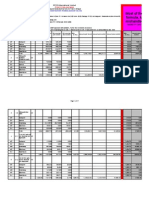

Sl. Author Year Coal Type Optimum condition Yield or

No. recovery

(%)

[1] M. Asghari 2018 coal size below 0.6 mm Gasoline and Kerosene collectors. 90

et. al from Anjir–Tangeh MIBC and Pine oil) as frothers.

(Zirab) coal washing Collector kerosene 3000 g/t, frother pine oil 40 g/ t, solid

plant. percentage 10%, and impeller speed 1000 rpm. optimum

conditions.

[2] P.S.R. Reddy 1988 Coal fines below 500 µm Light diesel oil as collector. 71.9

et. al from Sudamdih (India) Pine oil and MIBC in the ratio of 50:50 frother.

Collector 2 g/kg and frother 0.3 ml/l

[3] Z. Chang et. 2017 coal size below 0.2 mm Industrial-grade diesel as collector. 91.92

al from Bulli Mine, Australia Industrial grade MIBC as frother.

Slurry water pH adjusted to 8.

[4] O.H. Han et. 2014 coal size below 0.15 mm Kerosene a typical coal collector. 85

al from HwaSun Coal Mine MIBc and pine oil are used as frother.

in South Korea Sodium metaphosphate (SMP) and Sodium silicate are used

as depressants.

Air rate, wash water rate, feed solids concentration, frother

(MIBC) dosage, collector dosage, and depressant (SMP)

dosage are 1 cm/s, 0.3 cm/ s, 7% by mass, 0.15 ml/L, 0.2

kg/t and 3 kg/t, respectively.

Date: 21/12/2023 Minor Project Presentation Page No: 02

Literature Review contd.

[5] S.R.S. Sastri 1988 Coking coal size below light diesel oil as collector. 50.5

et. al 500µm from Sudamdih, pine oil and MIBC in the ratio of 50:50 as frother. 74.1

Patherdih, Kathara, 100 mm dia × 2300 mm high flotation column. 74.0

Moonidih (India) 78.8

[6] M. Ozmak and 2006 Coal size below 0.53mm Triton x-100, dispersant and surface modifier for coals. 84%

Z. Aktas from Zonguldak colliery. The reagents (MIBC and SDS) are commonly used in the (recovery)

froth flotation of coal.

[7] K. L. Bharatha 2021 Coal size below 0.50mm iluppai oil (95% pure oil) and light Diesel oil as collectors. 81.3% with

et. al from coal washery Methyl Isobutyl Carbinol (MIBC) is used as the frother. diesel oil

Moonidih, BCCL, pH is adjusted to 7.0. 85.6% with

Dhanbad, Jharkhand, The impeller speed of the machine was set at 1200 rpm iluppai oil

India and kept constant in all the tests.

[8] N. Vasumathi 2016 Coal size below 0.50mm Diesel is used as a collector. 72.18

et. al from North Karanpura MIBC as frother.

(Jharkhand, India).

Optimum process parameters are collector dosage

(diesel: 2.87 kg/t) and frother dosage (MIBC: 0.65 kg/t)

and flotation column operating parameters like froth depth

(600 mm), superficial feed velocity (0.57 cm/s), al air

velocity (0.78 cm/s) and feed pulp consistency of 9 %

solids by weight

Date: 21/12/2023 Minor Project Presentation Page No: 02

Literature Review contd.

[9] G. Harbort 2006 Coal size below Two-stage system of Jameson cell; 3500 mm × 1500 mm for 77.0

and D. 20–25(µm) from the first stage and 3000 mm × 1500 mm for the second 78.1

Alexander NEWLANDS coal in stage. 79.5

Queensland. Diesel oil as collector 75.4

MIBC as frother.

[10] P. 1992 Coal size below Reverse and forward flotation; 2 m high column; 88.7

STONESTRE 150 (µm) High Quaternary amine as ash collector (recovery

ET and J.-P. volatile, bituminous B Hexadecyl as coal depressant )

FRANZIDIS rank blend coking Trimethyl ammonium bromide(HTAB) as frother.

coal from the Witbank

No.2 seam.

[11] M.S. Jena et. 2008 Coal size below 1mm Kerosene oil was used as a collector. > 90

al from South Bolanda pine oil as frother. (recovery

mine, Talcher sodium hexametaphosphate was used as a silica )

coalfield, Orissa, India depressant as well as a dispersant.

Ethanol and butanol were used as reagents to enhance the

floatability of coal.

The optimum condition for flotation of −1 mm size fraction

by flotation column: Height of the flotation zone = 1.5 m,

Height of the cleaning zone = 1.0 m, Collector Kerosene oil

= 2 ml/kg, Frother Pine oil = 0.3 ml/kg, Promoter Black oil =

1.5 ml/kg, Air rate = 6–7 l/min, Wash water rate = 2–2.5

l/min, Solid concentration ≈10%, Feed rate = 4 l/min

Date: 21/12/2023 Minor Project Presentation Page No: 02

Principal of Froth Flotation

Cells

Agitator

Sparger

Regulator

Fig 3: Flotation Unit

Date: 21/12/2023 Minor Project Presentation Page No: 02

You might also like

- Combined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationDocument9 pagesCombined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationAndrew MwambaNo ratings yet

- Vedant Development 1Document1 pageVedant Development 1NIK GAMINGNo ratings yet

- Cost AnalysisDocument13 pagesCost Analysisnaveen yadavNo ratings yet

- Starworth 1Document1 pageStarworth 1KIRAN GNo ratings yet

- HPS Sumur Bor1Document72 pagesHPS Sumur Bor1Harianto PnsNo ratings yet

- Concrete Mix Design C 25 For KamoaDocument9 pagesConcrete Mix Design C 25 For KamoaMitendra Kumar ChauhanNo ratings yet

- Concrete Moisture Correction SheetDocument7 pagesConcrete Moisture Correction SheetAmit MaityNo ratings yet

- Thar Coal Utilization 30 June 2022 - 08042024 - FinalDocument4 pagesThar Coal Utilization 30 June 2022 - 08042024 - Finalmaaas81No ratings yet

- Vedant Propertis Royal 1Document1 pageVedant Propertis Royal 1NIK GAMINGNo ratings yet

- Contractor Consultant: Republic of Kenya Ministry of Roads and Public WorksDocument4 pagesContractor Consultant: Republic of Kenya Ministry of Roads and Public WorksGikonyoNo ratings yet

- 01-Concrete Mix + MED CertDocument21 pages01-Concrete Mix + MED CertAnwar SadathNo ratings yet

- Knowles Electronics Phils. Cebu Light Industrial Park, Lapu-Lapu CityDocument2 pagesKnowles Electronics Phils. Cebu Light Industrial Park, Lapu-Lapu CityEJ TabamoNo ratings yet

- Nh-44a Work Program Upto 31.12.2019 For Rce-IIDocument1 pageNh-44a Work Program Upto 31.12.2019 For Rce-IIMAROTHU MOHAN MANOJNo ratings yet

- Design Mix Summary: For Contractor (KOYA & CC) For Authority Engineer Name Name Designation Designation Date DateDocument4 pagesDesign Mix Summary: For Contractor (KOYA & CC) For Authority Engineer Name Name Designation Designation Date DateCar ThickNo ratings yet

- Concrete Mix Design C 30 For KamoaDocument9 pagesConcrete Mix Design C 30 For Kamoamitendra singhNo ratings yet

- Overview On The Indian Cement Sector and Its Changing Coal RequirementsDocument28 pagesOverview On The Indian Cement Sector and Its Changing Coal RequirementsNEELNo ratings yet

- PF-1 Bill Mar 2008Document17 pagesPF-1 Bill Mar 2008api-3823524No ratings yet

- Partial Replacement of Cement With Waste Paper Sludge AshDocument11 pagesPartial Replacement of Cement With Waste Paper Sludge AshIJRASETPublicationsNo ratings yet

- Sno Description Unit Rate Rs. Amount RS.: Data 2020-21 QuantityDocument24 pagesSno Description Unit Rate Rs. Amount RS.: Data 2020-21 QuantitysagarNo ratings yet

- Meltio-Nickel-625 Material Datasheet PDFDocument2 pagesMeltio-Nickel-625 Material Datasheet PDFJakNo ratings yet

- Cement Replace Wood AshDocument7 pagesCement Replace Wood AshM JOSEPH DAVID SELVANNo ratings yet

- PQC Mix Design 01 (Camp 01) 1Document120 pagesPQC Mix Design 01 (Camp 01) 1Imran Khan67% (3)

- By HMP (Analysis)Document7 pagesBy HMP (Analysis)Prashant VermaNo ratings yet

- BOQ Sumur Bor2Document72 pagesBOQ Sumur Bor2Harianto PnsNo ratings yet

- Sow System MDPDocument1 pageSow System MDPpernando silalahiNo ratings yet

- 3 GVP WeDocument22 pages3 GVP Wemurlikrishna3014887No ratings yet

- Netc DBMDocument34 pagesNetc DBMMorya RonakNo ratings yet

- Partial Replacement of Sand by Granite Powder in Concrete: Narmatha.M Vishali.G Noveena.SDocument5 pagesPartial Replacement of Sand by Granite Powder in Concrete: Narmatha.M Vishali.G Noveena.Sshivanand hippargaNo ratings yet

- Burnt Bricks Wall With RCC Slab (6) Classroom School Bill of Quantity (BOQ)Document16 pagesBurnt Bricks Wall With RCC Slab (6) Classroom School Bill of Quantity (BOQ)wafiullah sayedNo ratings yet

- Specification For Precast ChamberDocument6 pagesSpecification For Precast ChamberTai ChoonNo ratings yet

- Fencing To Cremitorium4Document3 pagesFencing To Cremitorium4K KARTHIKNo ratings yet

- BA SummaryDocument7 pagesBA SummaryPadmalavMahatoNo ratings yet

- ARCH 381 ThermodynamicsDocument11 pagesARCH 381 ThermodynamicsElanur MayaNo ratings yet

- 01 BOQ and Rate Analysis - Kolar-Kanhan Barrage 11122019.Document2 pages01 BOQ and Rate Analysis - Kolar-Kanhan Barrage 11122019.Prashant HuddarNo ratings yet

- 450mm Dia Hume Pipes CostDocument4 pages450mm Dia Hume Pipes Costnag00naNo ratings yet

- Rakesh R S Saudi Tabreed District CoolingDocument19 pagesRakesh R S Saudi Tabreed District CoolingAbdul Aziz Abdul Razak KedahNo ratings yet

- Bill of Quantity (Boq) (8) Class Room (Brick Masonry+ RCC Slab) (3mhight)Document26 pagesBill of Quantity (Boq) (8) Class Room (Brick Masonry+ RCC Slab) (3mhight)wafiullah sayedNo ratings yet

- Biweekly ProgressDocument1 pageBiweekly ProgressIkhsan BakhrullohNo ratings yet

- 1.summary of Concrete Mix DesignsDocument2 pages1.summary of Concrete Mix DesignsGanesh Kumar TulabandulaNo ratings yet

- Culvert Final Version in EnglishDocument12 pagesCulvert Final Version in Englishdeven gcNo ratings yet

- Toromocho Jan2017 Competent Persons ReportDocument147 pagesToromocho Jan2017 Competent Persons Reportmaría joséNo ratings yet

- Brick Masonry Rate AnalysisDocument2 pagesBrick Masonry Rate AnalysisersrcivilNo ratings yet

- Lab 1Document8 pagesLab 1Maica Joyce C. MonsalesNo ratings yet

- Changeover 1.1Document4 pagesChangeover 1.119512113No ratings yet

- Site Grading, Subgrade Excavate (Cut & Fill) Excavation (Cut) & Backfilling Compacted To 90% MDDDocument13 pagesSite Grading, Subgrade Excavate (Cut & Fill) Excavation (Cut) & Backfilling Compacted To 90% MDDEdgar QuinonesNo ratings yet

- M20 Kerb - Mix Design Calculation: Volume of Cementicious Materials+Water+AdmixtureDocument1 pageM20 Kerb - Mix Design Calculation: Volume of Cementicious Materials+Water+Admixturevdbshamsabad labNo ratings yet

- K-100 7hariDocument1 pageK-100 7harideasyaja1212No ratings yet

- Bill SampleDocument2 pagesBill SampleSayyidMahmoodThangalKVNo ratings yet

- DPR-BGR17 6.8.23 - Bridge FabricationDocument1 pageDPR-BGR17 6.8.23 - Bridge FabricationSivamurugan SivanayagamNo ratings yet

- WP Contentuploads202311EMSTEEL Investor Presentation 11.2023 v1.PDF 2Document40 pagesWP Contentuploads202311EMSTEEL Investor Presentation 11.2023 v1.PDF 2g00089664No ratings yet

- En Materi Pe Gems 22 Nov 2022Document34 pagesEn Materi Pe Gems 22 Nov 2022Herman TaniwanNo ratings yet

- S/No. Item A/U Qty Density WT of Mix in MT WT of Bitumen in MT WT of Agg in MTDocument5 pagesS/No. Item A/U Qty Density WT of Mix in MT WT of Bitumen in MT WT of Agg in MTM.E. TECHNOLOGYNo ratings yet

- Summary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCDocument3 pagesSummary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCmeerut nazibabad projectNo ratings yet

- Urban: Pay Date Cac No. Amount Paid Punch DateDocument1 pageUrban: Pay Date Cac No. Amount Paid Punch DateakhileshNo ratings yet

- Q3 Meeting SMCL HR.Document5 pagesQ3 Meeting SMCL HR.Santosh KumarNo ratings yet

- 2-Detailed Cost EstimateDocument62 pages2-Detailed Cost Estimateanuj khadkaNo ratings yet

- Marshall Stability Test PDFDocument8 pagesMarshall Stability Test PDFAnonymous FO4sHLLONo ratings yet

- Partial Replacement of Sand With Sawdust in Concrete ProductionDocument7 pagesPartial Replacement of Sand With Sawdust in Concrete ProductionkimNo ratings yet

- ProdPlan 2017.R4.TVBzDocument54 pagesProdPlan 2017.R4.TVBzbinsarNo ratings yet

- MetallographyDocument7 pagesMetallographyMehmet Ali CanNo ratings yet

- CHEN2000 FinalDocument10 pagesCHEN2000 FinalKHÁNH VÂN DIỆPNo ratings yet

- N H S Office Complex: 3100 S. Figueroa Street Los Angeles, Ca 90007Document1 pageN H S Office Complex: 3100 S. Figueroa Street Los Angeles, Ca 90007Rafael SathlerNo ratings yet

- Chemistry 2: Modified Strategic Intervention MaterialsDocument9 pagesChemistry 2: Modified Strategic Intervention MaterialsJenny Mae LopezNo ratings yet

- PRC 140625040720 Phpapp02Document12 pagesPRC 140625040720 Phpapp02besartNo ratings yet

- SDS 80 Fat Unsalted Butter Lactic AcidDocument8 pagesSDS 80 Fat Unsalted Butter Lactic Acidfiyan maulanaNo ratings yet

- Iron Metallurgy by Nwaogbe JohnDocument26 pagesIron Metallurgy by Nwaogbe JohnDavid UdohNo ratings yet

- Precast EnvelopeDocument70 pagesPrecast Envelopesdutta2591No ratings yet

- Tile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncDocument4 pagesTile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncRoland CepedaNo ratings yet

- Rockwool 159Document37 pagesRockwool 159ashish2783No ratings yet

- Colligative PropertiesDocument41 pagesColligative PropertiesJoshua SagunNo ratings yet

- BenedictDocument5 pagesBenedictMark Justin LealNo ratings yet

- 3D ConsolidationDocument25 pages3D ConsolidationHashir ChNo ratings yet

- Vacuum Coating of Plastic OpticsDocument15 pagesVacuum Coating of Plastic OpticsSasiKumar PetchiappanNo ratings yet

- Analysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Document2 pagesAnalysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Eustache NIJEJENo ratings yet

- Electron BeamDocument5 pagesElectron Beamrangaraobdl30198No ratings yet

- SuperkonduktorDocument18 pagesSuperkonduktorMuhammad Reihan IskandarNo ratings yet

- Welding Electrode ChartDocument2 pagesWelding Electrode ChartZaheed Manoo50% (2)

- Transport Phenomena III: Mass Transfer Chapter 28: Convective Mass TransferDocument23 pagesTransport Phenomena III: Mass Transfer Chapter 28: Convective Mass Transferنزار الدهاميNo ratings yet

- Chemical Effects of ElectricityDocument9 pagesChemical Effects of ElectricityJay Sunga VillanNo ratings yet

- Soil Properties and Soil MechanicsDocument7 pagesSoil Properties and Soil Mechanicsnixen99_gellaNo ratings yet

- Code Osff Practice RC 50022 Selection and Design of Pavements and SurfacingsDocument21 pagesCode Osff Practice RC 50022 Selection and Design of Pavements and Surfacingslosmi91No ratings yet

- NCMA Thermal Catalog of Concrete Masonry AssembliesDocument96 pagesNCMA Thermal Catalog of Concrete Masonry AssembliesestanilorenteNo ratings yet

- 1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgDocument13 pages1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgbanhrangNo ratings yet

- Sandvik Oilgas Hydraulic and Instrumentation Brochure S Tu278 EngDocument14 pagesSandvik Oilgas Hydraulic and Instrumentation Brochure S Tu278 EngDejan AntanasijevicNo ratings yet

- DESERT Solar CellsDocument2 pagesDESERT Solar CellsAndrew AtotuomahNo ratings yet

- Ms ProofDocument4 pagesMs Proofrizky efrinaldoNo ratings yet

- Minimum Pressurization TemperatureDocument4 pagesMinimum Pressurization TemperatureRonald MesinaNo ratings yet

- Notes On Applied GeologyDocument35 pagesNotes On Applied Geologyavula43No ratings yet

- FRP Unlimited: Connecting Professionals To The Value of Fibre Reinforced PlasticsDocument5 pagesFRP Unlimited: Connecting Professionals To The Value of Fibre Reinforced Plasticsargentino_ar01No ratings yet