Professional Documents

Culture Documents

Actuator Benchmark Results

Actuator Benchmark Results

Uploaded by

Dr. MarwaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Actuator Benchmark Results

Actuator Benchmark Results

Uploaded by

Dr. MarwaCopyright:

Available Formats

1

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

Sergej Jegorov, Piotr Wasiewicz

ACTUATOR BENCHMARK RESULTS:

STEP I AND II

2

Presentation Plan

• Control Valve Introduction

• Step I

• Step II

• Conclusions

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

3

Control Valve Introduction

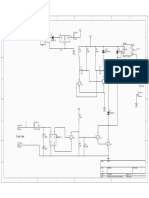

Actuator

Actuator structure

structure

Process

ProcessVariable

Variable

•• CV

CV –– Control

ControlValue

Value

•• ZZ –– Valve Position

Valve Position

•• P1

P1 –– Valve

Valve Input

Input Pressure

Pressure

•• P2

P2 –– Valve

Valve Output

Output Pressure

Pressure

•• FF –– Medium Flow

Medium Flow RateRate

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

4

Considered models of control valve

• servomotor rod movement model

Zˆ f (CV ) (1)

• control valve model

Fˆ f ( Z , P1 , P2 ) (2)

• actuator model

Fˆ f (CV , P1 , P2 ) (3)

• simplified model of the control valve

Fˆ f ( Z ) (4)

• simplified model of actuator

Fˆ f (CV ) (5)

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

S5

S4

S3

S2

S1

Valve clogging

f1

±1

±1

±1

Valve plug or valve seat

-1

-1

-1

-1

f2

sedimentation

1

1

1

1

f3

Valve plug or valve seat erosion

r4 = F – F*(Z),

r5 = F – F*(CV),

r1 = Z – Z*(CV),

Increased of valve or bushing

f4

±1

±1

±1

friction -1

-1

-1

-1

f5

External leakage

Control valve vaults

1

1

1

1

f6

Internal leakage Valve clogging

(9)

(6)

r3 = F – F*(CV, P1, P2), (8)

r2 = F – F*(Z, P1, P2), (7)

(10)

Medium evaporation or critical

-1

f7

±1

±1

±1

±1

flow

Twisted servo-motor's piston rod

f8

±1

±1

±1

Servo-motor's housing or terminals

1

1

-1

f9

tightness

faults

Servo-motor's diaphragm

1

1

-1

f10

perforation

Pneumatic servo-motor

Servo-motor's spring fault

f11

Electro-pneumatic transducer

S4 = f(r4),

S3 = f(r3),

S2 = f(r2),

S1 = f(r1),

S5 = f(r5).

±1

±1

±1

f12

fault

Rod displacement sensor fault

±1

±1

±1

±1

f13

Pressure sensor fault

X

X

X

X

X

f14

Positioner faults

Positioner feedback fault

(15)

(14)

(13)

(12)

(11)

±1

±1

±1

f15

Positioner supply pressure drop

Diagnostic Matrix (theoretical)

1

1

-1

f16

Unexpected pressure change across

±1

±1

f17

the valve

Fully or partly opened bypass

1

1

1

1

f18

valves

External faults

Flow rate sensor fault

-1

-1

-1

-1

f19

5

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

6

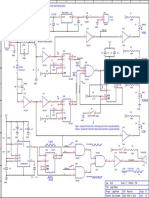

FDI Structure

FD using NN, FI using Fuzzy Logic

Inputs Outputs

Process + Residuals Faults

-

Fuzzy logic

Controller

Neural Network

Fault detection Fault isolation

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

7

Search of Optimal NN Architecture

• Transfer functions of

all layers are logsig

1 2 3

Name Delays

Layer Layer Layer

Net 2 10 5 1

Net1 2 30 8 1

Net3 2 6 3 1

Net4 2 6 1 0

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

9

Data Filtering

1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 f_t

input_f4i z z z z z z z z z z z

z z z z z

1/12 f_2f

1/6 input_f_f4i

filter1 filter2

1 1 1 1 1 1 1 1 1 1 1

f_ t

z z z z z z z z z z z

f_ 3f

1/24

1 1 1 1 1 1 1 1 1 1 1

z z z z z z z z z z z

filter3

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

10

NN Architecture Search. Training data without filtering

0.8

0.8 net1 0.6

0.6 net2

0.6 0.4

0.6 0.4

0.4 0.2

0.4 0.2

0.2 0

0.2 0

0 -0.2

0 -0.2

-0.2 -0.4

-0.2 -0.4

-0.4 -0.6

-0.4 -0.6

-0.6 -0.8

0 1000 2000 3000 4000 5000 6000 0 1000 2000 3000 4000 5000 6000

-0.6 -0.8

0 1000 2000 3000 4000 5000 6000 0 1000 2000 3000 4000 5000 6000

net4

0.6

net3

0.6

0.6

0.6

0.4

0.4

0.4

0.4

0.2

0.2

0.2

0.2

0

0

0

0

-0.2

-0.2

-0.2

-0.2

-0.4

-0.4

-0.4

-0.4

-0.6

-0.6

-0.6

-0.6

-0.8

0 1000 2000 3000 4000 5000 6000

-0.8

-0.8 0 1000 2000 3000 4000 5000 6000

0 1000 2000 3000 4000 5000 6000

-0.8

0 1000 2000 3000 4000 5000 6000

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

11

Results achieved by applying filtering of measurements

0.6 0.6

0.6 0.6

0.4 0.4

0.4 0.4

0.2 0.2

0.2 0.2

0 0

0 0

-0.2 -0.2

-0.2 -0.2

-0.4 -0.4

-0.4 -0.4

-0.6 -0.6 Blue – NN trained on filtr1

-0.6 -0.6

Red – NN trained on filtr2

-0.8 -0.8

0

-0.8 1000 2000 3000 4000 5000 6000 0

-0.8 1000 2000 3000 4000 5000 6000

0 1000 2000 3000 4000 5000 6000 0 1000 2000 3000 4000 5000 6000

Fault f4 Fault f4

Trained on filter1 but works on filter2 Trained on filter1 and filter2, but works on filter3

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

Time Diagrams of real and modeled signals. NN trained 12

applying filter2, but examined using filter3

1

1 NNr2 1

1 NNr3

0.9 0.9

0.9 0.9

0.8 0.8

0.8 0.8

0.7 0.7

0.7 0.7

0.6 0.6

0.6 0.6

0.5 0.5

0.5 0.5

0.4 0.4

0.4 0.4

0.3 0.3

0.3 0.3

0.2 0.2

0.2 0.2

0.1 0.1

0.1 0.1

0 0

00 0.5 1 1.5 2 2.5 00 0.5 1 1.5 2 2.5

0 0.5 1 1.5 2 4 2.5 0 0.5 1 1.5 2 4 2.5

x 10 x 10

4 4

x 10 x 10

0.1

0.1 r2 res 0.4

0.4

r3 res

0.05

0.05 0.2

0.2

0

0

0

-0.05 0

-0.05

-0.1 -0.2

-0.1 -0.2

-0.15

-0.15 -0.4

-0.4

-0.2

-0.2

-0.6

-0.6

-0.25

-0.25

-0.8

-0.3

-0.8

-0.3

-0.35 -1

0

-0.35 0.5 1 1.5 2 2.5 0-1 0.5 1 1.5 2 2.5

0 0.5 1 1.5 2 4 2.5

0 0.5 1 1.5 2 4 2.5

x 10 x 10

4

x 10 x 10

4

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

Time Diagrams of real and modeled signals. NN trained applying 13

filter2, but examined using filter3

1 1

1 1

0.9 0.9

0.9 0.9

0.8 0.8

0.8 0.8

0.7 0.7

0.7 0.7

0.6 0.6

0.6 0.6

0.5 0.5

0.5 0.5

0.4 0.4

0.4 0.4

0.3 0.3

0.3 0.3

0.2 0.2

0.1

0.2

NNr4 0.1

0.2

NNr5

0.1 0.1

0 0

00 0.5 1 1.5 2 2.5 00 0.5 1 1.5 2 2.5

0 0.5 1 1.5 2 4 2.5 0 0.5 1 1.5 2 4 2.5

x 10 x 10

4 4

x 10 x 10

0.2 1

0.2 1

0.1 0.8

0.1 0.8

0.6

0

0.6

0

0.4

-0.1 0.4

-0.1

0.2

-0.2 0.2

-0.2

0

0

-0.3

-0.3

-0.2

-0.2

-0.4

-0.4 -0.4

-0.4

-0.5

-0.5 -0.6

-0.6

-0.6

r4 residual -0.6

-0.8

r5 residual

-0.8

-0.7 -1

0

-0.7 0.5 1 1.5 2 2.5 0-1 0.5 1 1.5 2 2.5

0 0.5 1 1.5 2 4 2.5

0 0.5 1 1.5 2 4 2.5

x 10 x 10

4

x 10 x 10

4

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

14

Measures of a Neural Networks "health"

All Weights and Biases All Weights and Biases

120 40

35

100

30

80

25

60 20

15

40

10

20

5

0 0

-11 -9 -7 -5 -3 -1 1 3 5 7 9 11 -11 -9 -7 -5 -3 -1 1 3 5 7 9 11

All Weights and Biases All Weights and Biases

40 30

35

25

30

20

25

20 15

15

10

10

5

5

0 0

-11 -9 -7 -5 -3 -1 1 3 5 7 9 11 -11 -9 -7 -5 -3 -1 1 3 5 7 9 11

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

S5

S4

S3

S2

S1

Valve clogging

f1

+1

+1

+1

Valve plug or valve seat

-1

-1

-1

-1

f2

sedimentation

Valve plug or valve seat erosion

f3

+1

+1

+1

+1

Increased of valve or bushing

f4

+1

+1

+1

friction

External leakage

x

x

x

x

x

f5

Control valve vaults

Internal leakage Valve clogging

f6

+1

+1

+1

+1

Medium evaporation or critical flow

f7

+1

+1

+1

Twisted servo-motor's piston rod

x

x

x

x

x

f8

Servo-motor's housing or terminals

x

x

x

x

x

f9

tightness

Servo-motor's diaphragm perforation

+1

+1

+1

motor faults

Pneumatic servo-

x

x

x

x

x

Servo-motor's spring fault

x

x

x

x

x

Electro-pneumatic transducer fault

Rod displacement sensor fault

+1

+1

+1

+1

X

X

X

X

X

Pressure sensor fault

Positioner faults

-1

-1

-1

Positioner feedback fault

+1

+1

+1

Positioner supply pressure drop

Unexpected pressure change across the

-1

-1

valve

+1

+1

+1

+1

Fully or partly opened bypass valves

External faults

0

0

0

0

0

+1

+1

+1

+1

Flow rate sensor fault .

f10 f11 f12 f13 f14 f15 f16 f17 f18 f19

free

Fault

1

0

1

0

1

f16

f1, f4,

f7, f10, f2

-1

-1

-1

-1

-1

Diagnostic Matrix (Practical)

1

1

1

1

0

f19

f18,

f13,

f3, f6,

0

0

0

0

0

f14

f12,

f5, f8,

f9, f11,

0

0

-1

-1

-1

f15

0

0

0

-1

-1

f17

DGN0 DGN1 DGN2 DGN3 DGN4 DGN5 DGN6

15

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

16

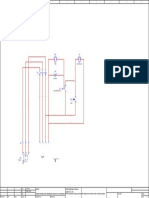

Fuzzification (Membership Functions)

Input Membership Functions Input Membership Functions

r1, r2, r4 r3, r5

• Sugeno Type

• Defuzzificatiom method is whatever (wtaver)

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

17

Examples of results of isolation of fault 1

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

18

Examples of results of isolation of fault 3

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

19

Step I results (from forms S1-FF-fx)

f1 f1m f2 f2inc f3inc f4inc f5inc f6inc f7 f7m f8 f9 f10 f11

td 5s 15s 2s 8.278e+004s 5.378e+004s 4130s - 1.672e+004s 5s 5s - - 5s -

rfd 0% 0% 0% 0% 0% 0% - 0% 0% 0% - - 0% -

rtd

0.98% 0.95% 0.99% 0.94% 0.72% 0.13% - 0.89% 0.98% 0.98% - - 0.98% -

fsd 0.75 0.5 0.75 0.98 0.64 1 - 0.19 0.75 0.5 - - 0.75 -

tit 5s 15s 2s 8.278e+004s 5.378e+004s 4130s - 1.672e+004s 5s 5s - - 5s -

rfi 0% 0% 0% 0% 0% 0% - 0% 0% 0% - - 0% -

rti 0.98% 0.95% 0.99% 0.92% 0.72% 0.02% - 0.89% 0.98% 0.98% - - 0.98% -

rmi 0% 0% 0.02% 0.38% 0.021% 0.12% - 0.01% 0.02% 0.01% - - 0.01% -

fsi 0.75 0.5 0.75 0.98 0.6403 1 - 0.19 0.75 0.5 - - 0.75 -

dacc 0.2 0.2 1 inf 0.2 0.2 - 0.2 0.2 0.2 - - 0.2 -

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

20

Step I results (from forms S1-FF-fx) continued

f12 f13 f13m f13inc f14 f15 f16 f17 f17 inc f18 f18m f18inc f19 f19m

td - 5s 6s 45s - 231s 7s 6s 640s 5s 6s 9409s 7s 7s

rfd - 0% 0% 0% - 0% 0% 0% 0% 0% 0% 0% 0% 0%

rtd

- 0.98% 0.97% 0.97% - 0.92% 0.97% 0.97% 0.91% 0.98% 0.97% 0.93% 0.97% 0.97%

fsd - 0.75 0.5 0.07 - 0.75 0.75 0.76 0.17 0.75 0.5 0.112 0.75 0.5

tit - 5s 6s 45s - 240s 7s 35s 640s 5s 6s 9409s 7s 7s

rfi - 0% 0% 0% - 0% 0% 0% 0% 0% 0% 0% 0% 0%

rti - 0.98% 0.97% 0.97% - 0.66% 0.97% 0.90% 0.91% 0.98% 0.97% 0.93% 0.97% 0.97%

rmi - 0.01% 0% 0% - 0.28% 0% 0.07% 0.03% 0% 0% 0% 0% 0%

fsi - 0.75 0.5 0.07 - 0.75 0.75 0.75 0.17 0.75 0.5 0.112 0.75 0.5

dacc - 0.2 0.2 0.2 - 0.07 0.2 1 1 0.2 0.2 0.2 0.2 0.2

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

21

Step II results

scenario 1 2 3 4 5 6 7 8 9 10 11 12

Fault or DGN5

DGN1 - DGN3 DGN5 - DGN5 DGN2 DGN5 DGN1 DGN1 DGN3

group or 1

Start time 15073 - 37619 82491 - 80965 62438 24809 20778 24129 855 55196

Stop time inf - 73370 82519 - 80979 76487 24821 49064 35621 11963 80822

scenario 13 14 15 16 17 18 19 20 21 22 23 24

Fault or

DGN6 DGN3 DGN5 DGN3 DGN3 DGN1 DGN1 - DGN2 DGN3 DGN3 DGN6

group

Start time 19817 58605 60001 30194 12430 1940 22556 - 18238 7400 5773 10717

Stop time 23743 77130 60014 Inf Inf 10039 35085 - Inf inf inf Inf

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

22

Conclusions

• fault detection subsystem based on neural network technology was

developed

• fault isolation subsystem based on fuzzy logic technology was

developed

• Neuro-fuzzy FDI system is applicable for actuator fault diagnosis.

Fault groups are distinguishable.

• Close to 1, true fault detection rates factors achieved in Step I

confirms acceptable NN models quality

• High values of true fault isolation rates (Step I) confirms proper

isolability features of fuzzy isolation scheme applied

• Results achieved in Actuator Benchmark Step I are highly

acceptable

• The fault distinguishability problem exists because of limited

availability of measurements when considering industrial

benchmark Step II). In this case 6 fault groups are distinguishable.

5-th DAMADICS Workshop

Łagów, Poland, April 5th-7th, 2004

You might also like

- 8Q-IAI - A321 - Cabin and Emergency Equipment Layout - Rev 05 - SignedDocument1 page8Q-IAI - A321 - Cabin and Emergency Equipment Layout - Rev 05 - SignedMugilanNo ratings yet

- Fingerprint Terminal Ac-2000 & Ac-2100Plus: Installation & Wiring GuideDocument18 pagesFingerprint Terminal Ac-2000 & Ac-2100Plus: Installation & Wiring GuideFirdaus NazmiNo ratings yet

- Hydraulic Component Design and SelectionDocument2 pagesHydraulic Component Design and SelectionAmitabhaNo ratings yet

- Nisshin Steel Cold Rolled Special Steel StripDocument28 pagesNisshin Steel Cold Rolled Special Steel StripekopujiantoeNo ratings yet

- Schematic - Tda2030 2.1 - 2020-06-12 - 00-09-10Document1 pageSchematic - Tda2030 2.1 - 2020-06-12 - 00-09-10Zubaidin ChannelNo ratings yet

- Scales Chords and ArpeggiosDocument36 pagesScales Chords and ArpeggiosdarkypyNo ratings yet

- Existing Packaging WarehouseDocument1 pageExisting Packaging WarehouseKate PerezNo ratings yet

- Stany Alpha V 1.0.0.1 COMPLETODocument1 pageStany Alpha V 1.0.0.1 COMPLETOLeonardo QuinteroNo ratings yet

- 9852 1404 01a Driving M2 C, L1 C, L2 CDocument2 pages9852 1404 01a Driving M2 C, L1 C, L2 CGustavo A. Utreras FariasNo ratings yet

- ElectricalWiringDiagram OverallDocument137 pagesElectricalWiringDiagram OverallY MP PasNo ratings yet

- P&id PreflexDocument1 pageP&id PreflexAndres FernándezNo ratings yet

- MFS Arduino PDFDocument1 pageMFS Arduino PDFDusmantha AnandaratneNo ratings yet

- Schema Shield Invatare ArduinoDocument1 pageSchema Shield Invatare ArduinoTokra2007No ratings yet

- All Use SMD Component If Possible: Snap Off BoardDocument6 pagesAll Use SMD Component If Possible: Snap Off Board王军No ratings yet

- PCBDocument1 pagePCBROHIT CHANDRASHEKHAR KUPPELURNo ratings yet

- Ampeg SVT-VRDocument5 pagesAmpeg SVT-VRjorgito ribeiroNo ratings yet

- Fisa Placa LogicaDocument4 pagesFisa Placa LogicaDragos CiocanNo ratings yet

- SCH Schematic1 2024-04-27Document1 pageSCH Schematic1 2024-04-27Juan LitardoNo ratings yet

- Rangkaian TA Rev 3 Ok - CTDocument4 pagesRangkaian TA Rev 3 Ok - CTBudi AlfianNo ratings yet

- Actividad 4 - Plano-ModeloDocument1 pageActividad 4 - Plano-ModeloCami BermeoNo ratings yet

- Mach Nguyen LyDocument1 pageMach Nguyen LyNguyễn Khắc HòeNo ratings yet

- Asco 314Document2 pagesAsco 314Aziz SaputraNo ratings yet

- Logic Probe SchematicDocument1 pageLogic Probe SchematicAnonymous HPlNDhM6ejNo ratings yet

- 3.DC ARNIEC Plan ConexiuniDocument1 page3.DC ARNIEC Plan ConexiuniRadu OprișNo ratings yet

- Impreza - Crosstrek 19my Pubno - G1348be Version - 11009Document15 pagesImpreza - Crosstrek 19my Pubno - G1348be Version - 11009Charlie SouzaNo ratings yet

- Biema b3000 SCHDocument2 pagesBiema b3000 SCHEmz TaperlaNo ratings yet

- Mini Doy Bag Machine-El Diagrama Eléctrico Y Diagrama NeumáticoDocument9 pagesMini Doy Bag Machine-El Diagrama Eléctrico Y Diagrama NeumáticoCarlos FloresNo ratings yet

- Draw By: Project: Client: Title: CHK Date: Draw Date:: Rev. Date Subject Name SignDocument4 pagesDraw By: Project: Client: Title: CHK Date: Draw Date:: Rev. Date Subject Name SignChief EngineerNo ratings yet

- Điều khiển quạt dùng timerDocument1 pageĐiều khiển quạt dùng timerCường TrịnhNo ratings yet

- BÀI TẠP GUITAR CƠ BẢN - TIẾT TẤU CƠ BẢNDocument3 pagesBÀI TẠP GUITAR CƠ BẢN - TIẾT TẤU CƠ BẢNThiên Đoàn Lê TrungNo ratings yet

- MCRC 22726 2019 Annexure-A1 31-05-2019Document3 pagesMCRC 22726 2019 Annexure-A1 31-05-2019KkNo ratings yet

- Scanning Key & 7segment DisplayDocument1 pageScanning Key & 7segment DisplayFi NaNo ratings yet

- Scattering Amplitudes in N 4 Super Yang MillsDocument36 pagesScattering Amplitudes in N 4 Super Yang MillsZain AteeqNo ratings yet

- VH 012 20 1-05-gbDocument1 pageVH 012 20 1-05-gbАлександрNo ratings yet

- 17 Ig5a General Io (20070507)Document2 pages17 Ig5a General Io (20070507)cocodrilo360No ratings yet

- MR - Ghazafar Ali Plot#1073, Overseas O6Document21 pagesMR - Ghazafar Ali Plot#1073, Overseas O6Fais ConstructionNo ratings yet

- DTMF TouchTone.Document12 pagesDTMF TouchTone.Gigin IgnatiusNo ratings yet

- Telephone 5th Ring DetectorDocument1 pageTelephone 5th Ring Detectorv2brother100% (1)

- Medium Voltage Busway CA en 6 2012Document8 pagesMedium Voltage Busway CA en 6 2012Dante AlvaNo ratings yet

- Vin Vout: TP13 TP13 TP12 TP12 TP14 TP14 TP15 TP15Document1 pageVin Vout: TP13 TP13 TP12 TP12 TP14 TP14 TP15 TP15Varun Kumar ChillaNo ratings yet

- Diagrama de Circuito Power Supply d461Document1 pageDiagrama de Circuito Power Supply d461api-3703813100% (3)

- LiftDocument1 pageLiftSantosh KolhatkarNo ratings yet

- Axis 1Document1 pageAxis 1ephremNo ratings yet

- e - Hakko - fx951 - ADocument2 pagese - Hakko - fx951 - ARizky WijayaNo ratings yet

- Schema PandaDocument6 pagesSchema PandaHossine ChouirefNo ratings yet

- Manual Ricoh Af InstDocument21 pagesManual Ricoh Af Instanon_748411981No ratings yet

- Frere Jacques Stands On His Head ExDocument1 pageFrere Jacques Stands On His Head ExAaaaaNo ratings yet

- VH 3112 1-05 3-gbDocument4 pagesVH 3112 1-05 3-gbАлександрNo ratings yet

- Power Supply CTN180-P схемаDocument1 pagePower Supply CTN180-P схемаAлександр ФедорчукNo ratings yet

- PSU400EV2 4auxDocument2 pagesPSU400EV2 4auxsandaruNo ratings yet

- 10 1 2 3 4 5 6 7 8 9 - X24VDC - X24VDC - S01: 1551429 4tpe1551429n0007Document2 pages10 1 2 3 4 5 6 7 8 9 - X24VDC - X24VDC - S01: 1551429 4tpe1551429n0007Ngọc Tuấn NguyễnNo ratings yet

- TDA2013Document1 pageTDA2013PhuongNo ratings yet

- Peugeot 4008 2012-2017 Service ManualDocument3,194 pagesPeugeot 4008 2012-2017 Service Manualjosefranciscodinamarca2003No ratings yet

- SchematicDocument25 pagesSchematicMohamed RafiudeenNo ratings yet

- PDU24HS General CircuitDocument1 pagePDU24HS General CircuitAndre BagaNo ratings yet

- Schematic - ESP32 - I - O 8 in - 8 Rel - 2022-04-28Document1 pageSchematic - ESP32 - I - O 8 in - 8 Rel - 2022-04-28Thamil AnbanNo ratings yet

- Diagrama Tarjeta QuinConDocument1 pageDiagrama Tarjeta QuinConcarlos andresNo ratings yet

- Manual de Partes 2545Document24 pagesManual de Partes 2545Andres MonteroNo ratings yet

- Circuito PCB Control Pedal V3Document1 pageCircuito PCB Control Pedal V3Marcelo PereiraNo ratings yet

- Schematic PDFDocument1 pageSchematic PDFDi NeverEndingNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- A Field Guide to the Aliens of Star Trek: The Next GenerationFrom EverandA Field Guide to the Aliens of Star Trek: The Next GenerationNo ratings yet

- Unit IIDocument61 pagesUnit IIHemanth Peddavenkatappa GariNo ratings yet

- Studi Kasus Kerusakan Silinder Liner Engine PC PDFDocument46 pagesStudi Kasus Kerusakan Silinder Liner Engine PC PDFApril KukuhNo ratings yet

- 11 Fracture MechanicsDocument31 pages11 Fracture MechanicsBanambar Singh100% (1)

- Cavitation DamageDocument18 pagesCavitation Damagescata1117No ratings yet

- Module 1 - Les #9 Influence Line-GirderDocument6 pagesModule 1 - Les #9 Influence Line-Girdercutie4everrNo ratings yet

- Steel Module8Document3 pagesSteel Module8dash1991No ratings yet

- Catalogue Condensate PumpDocument12 pagesCatalogue Condensate PumpMai Hữu NhânNo ratings yet

- 2D 1 Tutorial (090 206)Document117 pages2D 1 Tutorial (090 206)Kate MartinezNo ratings yet

- FSS 550 4X4 Regular Cab y Crew Cab Australia PDFDocument4 pagesFSS 550 4X4 Regular Cab y Crew Cab Australia PDFdionymackNo ratings yet

- Lecture 1 - Introduction PDFDocument11 pagesLecture 1 - Introduction PDFAndrésDíazNo ratings yet

- Zurn Aquaflush z6000 PartsDocument1 pageZurn Aquaflush z6000 Partsezequiel.barrioszamoraNo ratings yet

- Avk Butterfly Valves, Centric With Loose Liner: Series 820Document6 pagesAvk Butterfly Valves, Centric With Loose Liner: Series 820utzu_yooNo ratings yet

- Pexgol Engineering Guide 2015 (126 Páginas)Document126 pagesPexgol Engineering Guide 2015 (126 Páginas)danielbustNo ratings yet

- Bomba MORODocument29 pagesBomba MOROcesarvalenciaperdomoNo ratings yet

- Role Master SkillsDocument9 pagesRole Master Skillsmfhl2001No ratings yet

- hpv310 e Doc00061 PDFDocument38 pageshpv310 e Doc00061 PDFAnonymous v7XdaQuNo ratings yet

- 2TR17 - 2TR20 Yanmar1700a2000aparts-KatalognahradnichdiluDocument116 pages2TR17 - 2TR20 Yanmar1700a2000aparts-KatalognahradnichdiluГалина КарташоваNo ratings yet

- Basic Engine PrinciplesDocument31 pagesBasic Engine PrinciplesRayge HarbskyNo ratings yet

- Bridge Girders-Strength at TransferDocument11 pagesBridge Girders-Strength at TransferAndy AcousticNo ratings yet

- Pros and Cons of Engineering BranchesDocument6 pagesPros and Cons of Engineering BranchesAnuj KansalNo ratings yet

- Transmission and Differential SectionDocument242 pagesTransmission and Differential Sectionclaudiux78No ratings yet

- Heavy Equipment Oil ListDocument3 pagesHeavy Equipment Oil ListAris TacheazyNo ratings yet

- Design ReportDocument22 pagesDesign Reportamit_saxena_10No ratings yet

- CH. VII B Direct SDocument25 pagesCH. VII B Direct SHassan Abu AlsaudNo ratings yet

- Boyles LawDocument31 pagesBoyles LawJanetMagnayeLapitan100% (1)

- Diagrama Hidraulico Retroexcavadora 420F2 Serie NSBDocument2 pagesDiagrama Hidraulico Retroexcavadora 420F2 Serie NSBSteve Bolaños100% (1)

- FMC Product OverviewDocument32 pagesFMC Product OverviewGustavoSilvinoSilvinoNo ratings yet

- Cooling SystemDocument11 pagesCooling SystemAbera ZewduNo ratings yet