Professional Documents

Culture Documents

PT Acceptance Criteria

PT Acceptance Criteria

Uploaded by

ankit75880 ratings0% found this document useful (0 votes)

18 views8 pagesThe document discusses acceptance standards for liquid penetrant and magnetic particle nondestructive testing as defined by the ASME boiler and pressure vessel code. It states that only indications greater than 1.5 mm shall be considered relevant defects. A relevant linear indication is defined as having a length more than three times its width, while a relevant rounded indication has a length less than or equal to three times its width. Surfaces must be free of relevant linear indications, relevant rounded indications greater than 5 mm, or four or more relevant rounded indications in a line separated by 1.5 mm or less edge to edge to pass inspection.

Original Description:

Original Title

PT ACCEPTANCE CRITERIA

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses acceptance standards for liquid penetrant and magnetic particle nondestructive testing as defined by the ASME boiler and pressure vessel code. It states that only indications greater than 1.5 mm shall be considered relevant defects. A relevant linear indication is defined as having a length more than three times its width, while a relevant rounded indication has a length less than or equal to three times its width. Surfaces must be free of relevant linear indications, relevant rounded indications greater than 5 mm, or four or more relevant rounded indications in a line separated by 1.5 mm or less edge to edge to pass inspection.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

18 views8 pagesPT Acceptance Criteria

PT Acceptance Criteria

Uploaded by

ankit7588The document discusses acceptance standards for liquid penetrant and magnetic particle nondestructive testing as defined by the ASME boiler and pressure vessel code. It states that only indications greater than 1.5 mm shall be considered relevant defects. A relevant linear indication is defined as having a length more than three times its width, while a relevant rounded indication has a length less than or equal to three times its width. Surfaces must be free of relevant linear indications, relevant rounded indications greater than 5 mm, or four or more relevant rounded indications in a line separated by 1.5 mm or less edge to edge to pass inspection.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 8

ASME SEC IX

QUALIFICATION STANDARD FOR WELDING, BRAZING, AND FUSING PROCEDURES; WELDERS; BRAZERS; AND

WELDING, BRAZING, AND FUSING OPERATORS

QW-195.2 Liquid Penetrant Acceptance Criteria.

QW-195.2.1 Terminology.

Relevant indications: indications with major dimensions greater than 1.5 mm

Linear indications: an indication having a length greater than three times the width. L > 3W

Rounded indications: an indication of circular or elliptical shape with the length equal to or less than three times the

width. L ≤ 3W

QW-195.2.2 Acceptance Standards.

Procedure and performance tests examined by liquid penetrant techniques shall be judged unacceptable when the

examination exhibits any indication in excess of the limits specified in the following:

(a) relevant linear indications.

(b) relevant rounded indications greater than 5 mm.

(c) four or more relevant rounded indications in a line separated by 1.5 mm or less (edge-to-edge).

ASME B31.3 PROCESS PIPING

344.4 Liquid Penetrant Examination

344.4.1 Method. Examination of castings is covered in para. 302.3.3. Liquid penetrant examination of welds and of

components other than castings shall be performed in accordance with ASME BPVC, Section V, Article 6.

344.4.2 Acceptance Criteria. Liquid penetrant indications are caused by the bleed-out of a visible or fluorescent dye

from a surface discontinuity in the area under test. In advertent evidence of penetrant not related to actual bleed-

out is classified as a false indication. Indications shall be verified as being relevant, nonrelevant, or false. Additional

surface preparation and/or other test methods may be used as needed to verify the relevance of an indication.

An indication of an imperfection may be larger than the imperfection that causes it; however, the size of the

indication is the basis for acceptance evaluation. Only indications that have any dimension greater than 1.5 mm shall

be considered relevant.

(a) Indications

(1) A linear indication is one having a length greater than three times its width. L > 3W

(2) A rounded indication is one of circular or elliptical shape with a length equal to or less than three times its width.

L ≤ 3W

(b) Examination.

All surfaces to be examined shall be free of

(1) relevant linear indications

(2) relevant rounded indications >5.0 mm.

(3) four or more relevant rounded indications in a line separated by 1.5 mm or less, edge to edge

ASME B31.3 PROCESS PIPING

344.3 Magnetic Particle Examination

344.3.1 Method. Examination of castings is covered in para. 302.3.3. Magnetic particle examination of welds and

of components other than castings shall be performed in accordance with ASME BPVC, Section V, Article 7.

344.3.2 Acceptance Criteria. Magnetic particle indications are caused by the attraction of the test media to surface

or near-surface discontinuities in the area under test Indications shall be verified as being relevant, nonrelevant, or

false. Additional surface preparation and/or other test methods may be used as needed to verify the relevance of an

indication. An indication of an imperfection may be larger than the

imperfection that causes it; however, the size of the indication is the basis for acceptance evaluation. Only

indications that have any dimension greater than 1.5 mm shall be considered relevant.

(a) Indications

(1) A linear indication is one having a length greater than three times its width. L > 3W

(2) A rounded indication is one of circular or elliptical shape with a length equal to or less than three times its width.

L ≤ 3W

(b) Examination.

All surfaces to be examined shall be free of

(1) relevant linear indications

(2) relevant rounded indications >5.0 mm.

(3) four or more relevant rounded indications in a line separated by 1.5 mm or less, (edge to edge).

ASME SEC VIII DIV-1

RULES FOR CONSTRUCTION OF PRESSURE VESSELS

MANDATORY APPENDIX 8

METHODS FOR LIQUID PENETRANT EXAMINATION (PT)

8-3 EVALUATION OF INDICATIONS

An indication of an imperfection may be larger than the imperfection that causes it; however, the size of the

indication is the basis for acceptance evaluation. Only indications with major dimensions greater than 1/16 in. (1.5

mm) shall be considered relevant.

(a) A linear indication is one having a length greater than three times the width. L > 3W

(b) A rounded indication is one of circular or elliptical shape with the length equal to or less than three times the

width. L ≤ 3W

(c) Any questionable or doubtful indications shall be reexamined to determine whether or not they are relevant.

8-4 ACCEPTANCE STANDARDS

These acceptance standards shall apply unless other more restrictive standards are specified for specific materials or

applications within this Division.

All surfaces to be examined shall be free of:

(a) relevant linear indications;

(b) relevant rounded indications greater than 5 mm.

(c) four or more relevant rounded indications in a line separated by 1.5 mm or less (edge to edge).

ASME SEC VIII DIV-1

RULES FOR CONSTRUCTION OF PRESSURE VESSELS

MANDATORY APPENDIX 6

METHODS FOR MAGNETIC PARTICLE EXAMINATION (MT)

6-3 EVALUATION OF INDICATIONS

Indication will be revealed by retention of magnetic particles. All such indications are not necessarily imperfections,

however, since excessive surface roughness, magnetic permeability variations (such as at the edge of heat-affected

zones), etc., may produce similar indications.

An indication of an imperfection may be larger than the imperfection that causes it; however, the size of the

indication is the basis for acceptance evaluation. Only indications which have any dimension greater than 1.5 mm

shall be considered relevant.

(a) A linear indication is one having a length greater than three times the width.

(b) A rounded indication is one of circular or elliptical shape with a length equal to or less than three times its width.

(c) Any questionable or doubtful indications shall be reexamined to determine whether or not they are relevant.

6-4 ACCEPTANCE STANDARDS

These acceptance standards shall apply unless other more restrictive standards are specified for specific materials or

applications within this Division. All surfaces to be examined shall be free of:

(a) relevant linear indications;

(b) relevant rounded indications greater than 5 mm.

(c) four or more relevant rounded indications in a line separated by 1.5 mm or less, edge to edge.

Thank You

You might also like

- ASME B 31.1 Acceptance Criteria PDFDocument13 pagesASME B 31.1 Acceptance Criteria PDFasim alok swain100% (3)

- Autoclave Cleaning Log Sheet ExampleDocument23 pagesAutoclave Cleaning Log Sheet Exampleankit7588No ratings yet

- SOP 013 Product Identification and TraceabilityDocument7 pagesSOP 013 Product Identification and Traceabilityankit7588No ratings yet

- Pressure Testing Safety Checklist: SN Requirements RemarksDocument5 pagesPressure Testing Safety Checklist: SN Requirements RemarksIdada EzekielNo ratings yet

- Acceptance Criteria NDTDocument8 pagesAcceptance Criteria NDTBusairi Achmad100% (1)

- Asme Sec Viii D1 Ma App 6Document2 pagesAsme Sec Viii D1 Ma App 6ADRIANNo ratings yet

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pages7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Criterios de Aceptacion PT SiintegDocument10 pagesCriterios de Aceptacion PT SiintegManuel Andres Mantilla DuranNo ratings yet

- Astm A903Document2 pagesAstm A903sekharsappa100% (2)

- Astm A578 - 07 PDFDocument5 pagesAstm A578 - 07 PDFMuhammad Maulana100% (1)

- Mandatory Appendix 6 MTDocument2 pagesMandatory Appendix 6 MTTahar DabbarNo ratings yet

- Asme Acc Criteria MT PTDocument3 pagesAsme Acc Criteria MT PTGowrisanthosh Palika100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Interfacial Electrochemistry Theory Experiment and ApplicationsDocument961 pagesInterfacial Electrochemistry Theory Experiment and ApplicationsKaline Nascimento100% (1)

- HIt Products CatalogDocument51 pagesHIt Products CatalogmardonioandradeNo ratings yet

- MPT Mandatory Appendix 6Document2 pagesMPT Mandatory Appendix 6Ashfaq Khan100% (1)

- Mandatory Appendix 6 Methods For Magnetic Particle Examination (MT)Document2 pagesMandatory Appendix 6 Methods For Magnetic Particle Examination (MT)Usman TahirNo ratings yet

- Asme Section ViiiDocument1 pageAsme Section ViiiCesar GarciaNo ratings yet

- Mandatory Appendix 8 Methods For Liquid Penetrant Examination (PT)Document1 pageMandatory Appendix 8 Methods For Liquid Penetrant Examination (PT)diego raquiraNo ratings yet

- Asme Section ViiiDocument1 pageAsme Section ViiiCESAR RENE GARCIA SERPANo ratings yet

- Asme Viii Div I Ma App 8Document2 pagesAsme Viii Div I Ma App 8newryan0% (1)

- Asme Viii Division 1 2013 PTDocument2 pagesAsme Viii Division 1 2013 PTRonel John Rodriguez CustodioNo ratings yet

- Critére D'acceptation PT API 650 ASME VIIIDocument4 pagesCritére D'acceptation PT API 650 ASME VIIITahar DabbarNo ratings yet

- Man Appendix 6 PDFDocument2 pagesMan Appendix 6 PDFAshokMechNo ratings yet

- 8-1 SCOPE 8-3 Evaluation of IndicationsDocument2 pages8-1 SCOPE 8-3 Evaluation of IndicationsCristian ArellanoNo ratings yet

- ASME Sec Viii MTDocument2 pagesASME Sec Viii MTrashid isaarNo ratings yet

- NDT Acceptance CriteriaDocument2 pagesNDT Acceptance Criteriamoonstar_dme70% (20)

- Api 1104Document3 pagesApi 1104Tahar DabbarNo ratings yet

- Asme Section Viii Liquidos Penetrantes CriteriosDocument2 pagesAsme Section Viii Liquidos Penetrantes CriteriosLorena JimenezNo ratings yet

- Acceptance Criteria MT Asme 2018Document1 pageAcceptance Criteria MT Asme 2018Teodorsagevik1No ratings yet

- Criterios de Aceptacion y Rechazo Asme ViiiDocument4 pagesCriterios de Aceptacion y Rechazo Asme ViiiGAlberto VillaPerezNo ratings yet

- ASME VII 7.5.7 Liquid Penetrant Examination (PT)Document1 pageASME VII 7.5.7 Liquid Penetrant Examination (PT)Isti_MNo ratings yet

- Art 6 - MTDocument2 pagesArt 6 - MTcosme fulanitoNo ratings yet

- 6.ASME Section VIII, Man App 8 (2010)Document2 pages6.ASME Section VIII, Man App 8 (2010)NDT GMFNo ratings yet

- Asme VIII d1 Ma Appendix 8 PDFDocument2 pagesAsme VIII d1 Ma Appendix 8 PDFedisjdavNo ratings yet

- Secviii Div 2 - 7.5.6Document2 pagesSecviii Div 2 - 7.5.6Bhavin SukhadiyaNo ratings yet

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentSandipNo ratings yet

- API 1104 - UT Acceptance StandardsDocument5 pagesAPI 1104 - UT Acceptance StandardsABDIELNo ratings yet

- ASME Sec VIII d1 Ma App 8Document2 pagesASME Sec VIII d1 Ma App 8fuihiufhNo ratings yet

- Acceptance Criteria For NDT (UT, RT, DPT, Visual, MPT)Document5 pagesAcceptance Criteria For NDT (UT, RT, DPT, Visual, MPT)Naveen Kumar75% (4)

- 2013 Asme VIII Acceptance CriteriaDocument8 pages2013 Asme VIII Acceptance CriteriaSiggy LaiNo ratings yet

- PT - Asme Sec Viii Div. 1 2004 EditionDocument2 pagesPT - Asme Sec Viii Div. 1 2004 EditiondhasdjNo ratings yet

- Acceptance Criteria For Weld DefectsDocument6 pagesAcceptance Criteria For Weld DefectsMohamed AtefNo ratings yet

- RT Acceptance CriteriaDocument4 pagesRT Acceptance CriteriaSandipNo ratings yet

- Code Case - 2235-10Document10 pagesCode Case - 2235-10Nilesh Pathare0% (1)

- 9.6 Ultrasonic Testing: 9.5.3 Base Material ImperfectionsDocument3 pages9.6 Ultrasonic Testing: 9.5.3 Base Material ImperfectionstrivikramraoNo ratings yet

- Acceptance Criteria For RT and DPTDocument2 pagesAcceptance Criteria For RT and DPTArun Shishodia100% (1)

- ASME Code Case PautDocument10 pagesASME Code Case PautAnonymous kIrNuhNo ratings yet

- Straight-Beam Ultrasonic Examination of Steel Plates': Standard SpecificationDocument2 pagesStraight-Beam Ultrasonic Examination of Steel Plates': Standard SpecificationRegis KoroivaNo ratings yet

- ASTM - A 903 - Steel Castings, Surface Acceptance Standards - MT - PTDocument2 pagesASTM - A 903 - Steel Castings, Surface Acceptance Standards - MT - PTGeorge Hdlc100% (1)

- 01 Samss 022Document6 pages01 Samss 022aamirtec301No ratings yet

- Ductility of Oriented Electrical Steel: Standard Test Method ForDocument2 pagesDuctility of Oriented Electrical Steel: Standard Test Method Fornvh202148No ratings yet

- Ultrasonic Examination of Steel Forgings: Standard Practice ForDocument9 pagesUltrasonic Examination of Steel Forgings: Standard Practice ForK.s. Raghavendra KumarNo ratings yet

- Vitrified Clay Pipe: T 281 Methods of Sampling and TestingDocument3 pagesVitrified Clay Pipe: T 281 Methods of Sampling and TestingricardojesussardinasalzugarayNo ratings yet

- Juntas Tóricas CPI 8Document1 pageJuntas Tóricas CPI 8xavier castroNo ratings yet

- Standard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Document3 pagesStandard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Lupita RamirezNo ratings yet

- Páginas Desde ASME VIII - DIV.1Document2 pagesPáginas Desde ASME VIII - DIV.1daniel_break_1No ratings yet

- RT Asme IxDocument3 pagesRT Asme Ixhernando gelves100% (1)

- B31.3 Case 178Document11 pagesB31.3 Case 178fileseekerNo ratings yet

- General License Exam Cliff Note Manual 2015-2019From EverandGeneral License Exam Cliff Note Manual 2015-2019Rating: 1 out of 5 stars1/5 (1)

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- PED 2014 68 Eu Classification and CategoriesDocument36 pagesPED 2014 68 Eu Classification and Categoriesankit7588No ratings yet

- Iso 14469-2017Document44 pagesIso 14469-2017ankit7588No ratings yet

- SOP WeldingDocument3 pagesSOP Weldingankit7588No ratings yet

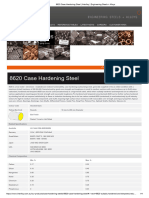

- 8620 Case Hardening Steel - Interlloy - Engineering Steels + AlloysDocument4 pages8620 Case Hardening Steel - Interlloy - Engineering Steels + Alloysankit7588No ratings yet

- 18 Measurement Systems AnalysisDocument118 pages18 Measurement Systems Analysisankit7588No ratings yet

- 4-8 SPC - Variables DataDocument59 pages4-8 SPC - Variables Dataankit7588No ratings yet

- 2.workshop ScheduleDocument1 page2.workshop Scheduleankit7588No ratings yet

- 2-15 Corr&SimpRegDocument72 pages2-15 Corr&SimpRegankit7588No ratings yet

- 15 FmeaDocument43 pages15 Fmeaankit7588No ratings yet

- 2-11 ANOVA Analysis of VarianceDocument81 pages2-11 ANOVA Analysis of Varianceankit7588No ratings yet

- 3-4 Full FactorialDocument111 pages3-4 Full Factorialankit7588No ratings yet

- 0575 User ManualDocument28 pages0575 User Manualankit7588No ratings yet

- Ocp PpeDocument3 pagesOcp Ppeankit7588No ratings yet

- 16.10 Cryogenic Material SafetyDocument5 pages16.10 Cryogenic Material Safetyankit7588No ratings yet

- Lean Six Sigma Green Belt Training CourseDocument14 pagesLean Six Sigma Green Belt Training Courseankit7588No ratings yet

- Preventive Maintenance Checking ParametersDocument7 pagesPreventive Maintenance Checking Parametersankit7588No ratings yet

- DS2063 Inox Eu enDocument28 pagesDS2063 Inox Eu enankit7588No ratings yet

- 0220 - Sop AutoclaveDocument6 pages0220 - Sop Autoclaveankit7588No ratings yet

- Lockout Tagout - Train The Trainer - 4 HOURSDocument1 pageLockout Tagout - Train The Trainer - 4 HOURSankit7588No ratings yet

- Re-Certification 2018Document1 pageRe-Certification 2018ankit7588No ratings yet

- DX58XXXXXX - 4 Child Part 2 RMDocument1 pageDX58XXXXXX - 4 Child Part 2 RMankit7588No ratings yet

- Diaphragm Valve ChineseDocument76 pagesDiaphragm Valve Chineseankit7588No ratings yet

- As9100 Procedure 753Document2 pagesAs9100 Procedure 753ankit7588No ratings yet

- Licences: 154. Application For Licence.Document7 pagesLicences: 154. Application For Licence.ankit7588No ratings yet

- IFPMA PP Traceability 03 - 2021Document7 pagesIFPMA PP Traceability 03 - 2021ankit7588No ratings yet

- Pump BrochureDocument10 pagesPump Brochuresen_subhasis_58100% (1)

- Unit 2 NotesDocument21 pagesUnit 2 NotesSandesh Kale100% (1)

- ASTM D1248 - pdqv6897Document8 pagesASTM D1248 - pdqv6897Nayth Andres GalazNo ratings yet

- Case Study - 2Document93 pagesCase Study - 2Amanpreet Singh100% (1)

- HuckelDocument167 pagesHuckelShivansh BhatnagarNo ratings yet

- Strain Energy PDFDocument27 pagesStrain Energy PDFIndhu ElangoNo ratings yet

- Underpotential Deposition of Lead On Single Crystal FacesDocument14 pagesUnderpotential Deposition of Lead On Single Crystal FacesAzucena osornio villaNo ratings yet

- Common Construction PT Issues ArticleDocument4 pagesCommon Construction PT Issues ArticleUdom RithNo ratings yet

- Certificate of Exclusivity - HRA + OCT EnglishDocument4 pagesCertificate of Exclusivity - HRA + OCT EnglishagmNo ratings yet

- Pipe Stress Critical Line ListDocument13 pagesPipe Stress Critical Line ListMohammed Tariq100% (1)

- Jt15d Ata 72 MaintDocument12 pagesJt15d Ata 72 MaintEgor85100% (1)

- ARH2203-assig#2 - Nickesh PargooDocument9 pagesARH2203-assig#2 - Nickesh PargooAnn DassNo ratings yet

- Previous Question Papers of Metallurgy and Material SciencesDocument10 pagesPrevious Question Papers of Metallurgy and Material SciencesRajeev SaiNo ratings yet

- Petrobowl Question Writing Guide and ExamplesDocument4 pagesPetrobowl Question Writing Guide and ExamplesDeonisio Yohanes Wilfridus HornayNo ratings yet

- Design of Semi-Rigid Steel Frames For Failure Mode ControlDocument23 pagesDesign of Semi-Rigid Steel Frames For Failure Mode ControlVincenzo PilusoNo ratings yet

- AgodaDocument82 pagesAgodaJolly LabroNo ratings yet

- PumpsDocument33 pagesPumpsSamson HaykonNo ratings yet

- SOP For Calibration of UV-Vis Spectrophotometer PharmaguidelineDocument7 pagesSOP For Calibration of UV-Vis Spectrophotometer PharmaguidelineMohamed IbrahimNo ratings yet

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocument3 pagesScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNo ratings yet

- On Plain Stress Analysis of A Composite BlockDocument11 pagesOn Plain Stress Analysis of A Composite BlockSrinivas NadellaNo ratings yet

- AP Chemistry - Electrochemical Cells LabDocument6 pagesAP Chemistry - Electrochemical Cells LabJonathan Chen100% (7)

- Unit8 Notes2Document3 pagesUnit8 Notes2Rameez FaroukNo ratings yet

- NSP PresentationDocument28 pagesNSP PresentationAkhand SinghNo ratings yet

- Elsworth VOM UV - PresentationDocument35 pagesElsworth VOM UV - Presentationrolandclaes100% (1)

- Chapter 5Document62 pagesChapter 5Mo Kops100% (1)

- Shigley Solve Cap. 5 &6Document63 pagesShigley Solve Cap. 5 &6Johnny SanchezNo ratings yet