Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

120 viewsFerrocement Water Tank Construction

Ferrocement Water Tank Construction

Uploaded by

Rajha RajeswaranThis document provides instructions for constructing a ferrocement tank in less than 3 sentences:

Ferrocement tanks are constructed by building a wire mesh frame, applying cement mortar in layers to form walls at least 2 inches thick, and constructing a domed roof using wood forms, rebar, wire mesh and more cement mortar before curing and finishing the tank.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Concrete Exposure Classes A23.1-19Document7 pagesConcrete Exposure Classes A23.1-19Steven SebastianNo ratings yet

- WASH Evaluation Solar Powered Water Supply Systems Somalia 2016-003Document60 pagesWASH Evaluation Solar Powered Water Supply Systems Somalia 2016-003kooj diriye100% (1)

- Alternative Building Techniques: 5 Architects and Their ProjectsDocument39 pagesAlternative Building Techniques: 5 Architects and Their ProjectsOmveer KumarNo ratings yet

- Lintel ClassificationDocument6 pagesLintel ClassificationsravanNo ratings yet

- Dib83-04 Caltrans CMP Culvert Repair Practices Manual PDFDocument210 pagesDib83-04 Caltrans CMP Culvert Repair Practices Manual PDFmm0493440No ratings yet

- Question Bank - MCQ - LandscapeDocument16 pagesQuestion Bank - MCQ - LandscapeASWIN KUMAR N S70% (10)

- Bathroom Remodel ChecklistDocument2 pagesBathroom Remodel ChecklistSol Farahmand100% (1)

- Ferro Cement Water TankDocument42 pagesFerro Cement Water TankbenzzenhdNo ratings yet

- Tehnology of ConstructionDocument11 pagesTehnology of ConstructionZenaida VoiculetNo ratings yet

- Pre Stressed BeamsDocument127 pagesPre Stressed BeamsjaffnaNo ratings yet

- Tie BarsDocument18 pagesTie BarsKutty Mansoor100% (1)

- Unit-3 (FRP & Ferrocement)Document27 pagesUnit-3 (FRP & Ferrocement)Mohammed Imran100% (1)

- IDE Lec8 Canal LiningDocument65 pagesIDE Lec8 Canal LiningFortiter FysproNo ratings yet

- Fly Ash Soil BlocksDocument42 pagesFly Ash Soil Blocksrafilu100% (1)

- Low Cost ConstructionDocument14 pagesLow Cost Constructionkaushita banerjee100% (1)

- Advantages of Shell Structures PDFDocument3 pagesAdvantages of Shell Structures PDFNeven Ahmed HassanNo ratings yet

- Is 9901-1 PDFDocument12 pagesIs 9901-1 PDFJGD123No ratings yet

- Gabion Walls For Form and Function - Backwoods Home MagazineDocument6 pagesGabion Walls For Form and Function - Backwoods Home Magazinesuasponte2No ratings yet

- All CladdingDocument44 pagesAll CladdingalloytarungNo ratings yet

- Pole Barn Metal DetailsDocument52 pagesPole Barn Metal DetailsKurt Stailey100% (1)

- Structural Steel Reuse in ConstructionDocument12 pagesStructural Steel Reuse in ConstructionMuhammad MurtazaNo ratings yet

- Canal Design1Document18 pagesCanal Design1Santosh Kumar DasNo ratings yet

- Analytical Research On Ferrocement: Design, Strength and Servicibility AspectsDocument8 pagesAnalytical Research On Ferrocement: Design, Strength and Servicibility AspectsPiyush SharmaNo ratings yet

- Innovative Uses of House Lifting Techniq PDFDocument15 pagesInnovative Uses of House Lifting Techniq PDFPandi AnNo ratings yet

- Wood Shingles and ShakesDocument6 pagesWood Shingles and Shakesjack.simpson.changNo ratings yet

- Performance Evaluation of High Strength Concrete With Partial Replacement of Saw DustDocument10 pagesPerformance Evaluation of High Strength Concrete With Partial Replacement of Saw DustInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Part 4 2 RMCdamDocument38 pagesPart 4 2 RMCdamKremen Mitov100% (1)

- Installation of Ceramic Tile in Swimming PoolsDocument5 pagesInstallation of Ceramic Tile in Swimming PoolsTenaw AlamirewNo ratings yet

- Lintel and ArchesDocument58 pagesLintel and ArchesVarinder SinghNo ratings yet

- Unit - 2: Advanced Concrete and Composite ReinforcementDocument89 pagesUnit - 2: Advanced Concrete and Composite Reinforcementsanjay saravananNo ratings yet

- Air Raid Shelters at ST Luke's and Warstones Schools, WolverhamptonDocument25 pagesAir Raid Shelters at ST Luke's and Warstones Schools, WolverhamptondigitalpastNo ratings yet

- Repair of Underwater Concrete StructuresDocument5 pagesRepair of Underwater Concrete StructuresRaja babuNo ratings yet

- Sea Sand Replacement With Fine AggregateDocument40 pagesSea Sand Replacement With Fine AggregateBHAVANA MNo ratings yet

- DIY Paving PDF 31103601924Document4 pagesDIY Paving PDF 31103601924Laki RevellosNo ratings yet

- DM PH&SD P7 TG02 (Guidelines+for+Approval+of+Swimming+Pool+Plans)Document5 pagesDM PH&SD P7 TG02 (Guidelines+for+Approval+of+Swimming+Pool+Plans)jbonvierNo ratings yet

- Ferrocement Construction Technology and Its Applications PDFDocument20 pagesFerrocement Construction Technology and Its Applications PDFPranavaDart0% (1)

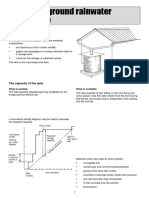

- Above-Ground Rainwater StorageDocument4 pagesAbove-Ground Rainwater StorageikaspuspasariNo ratings yet

- Some Innovative Steel StructuresDocument12 pagesSome Innovative Steel Structuresgurdan100% (2)

- Module 2 Pfrefab Components ComDocument86 pagesModule 2 Pfrefab Components ComAravinda NatikeriNo ratings yet

- Design, Manufacture and Test A Hydraulic Ram: ThesisDocument42 pagesDesign, Manufacture and Test A Hydraulic Ram: ThesisIrfan ShaikhNo ratings yet

- Radial WellsDocument44 pagesRadial Wellsidigiti100% (1)

- Hollow Slab / Concrete Beams MachineryDocument26 pagesHollow Slab / Concrete Beams Machineryprensoland100% (1)

- Soil Properties GuidlineDocument27 pagesSoil Properties GuidlineJulfikar KhanNo ratings yet

- Ce102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeDocument46 pagesCe102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeRomel BernardoNo ratings yet

- Sprayed ConcreteDocument27 pagesSprayed ConcreteSharanu PujariNo ratings yet

- Bamboo Space Frame Structures - Aug2012Document4 pagesBamboo Space Frame Structures - Aug2012Shriti DasNo ratings yet

- Build A Retaining WallDocument13 pagesBuild A Retaining WallAnonymous 1TTYYaNo ratings yet

- HB Assignment 2Document11 pagesHB Assignment 2Himanshu BishnoiNo ratings yet

- Fibre Reinforced ConcreteDocument6 pagesFibre Reinforced ConcreteFranklyn GenoveNo ratings yet

- Tipi Setup Catalog12 V6.0Document31 pagesTipi Setup Catalog12 V6.0victorNo ratings yet

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 pagesWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieNo ratings yet

- Monopole Mounts P70to88Document19 pagesMonopole Mounts P70to88robrebelNo ratings yet

- Auckland Soakhole Design Manual PDFDocument109 pagesAuckland Soakhole Design Manual PDFfrankmaggie850102No ratings yet

- FoundationDocument6 pagesFoundationAnonymous dK9Qi2XjNo ratings yet

- How I Built My Own Wind Turbine For My HouseDocument16 pagesHow I Built My Own Wind Turbine For My HouseAbu AsimNo ratings yet

- 1 Bridge Types and ClassificationsDocument65 pages1 Bridge Types and ClassificationsPraveen BhandariNo ratings yet

- Chapter 4 Roofs: Page 1 of Ch-4 A Lecture Note Compiled By: Er. Kishor ThapaDocument6 pagesChapter 4 Roofs: Page 1 of Ch-4 A Lecture Note Compiled By: Er. Kishor ThapaPratik Ghimire100% (1)

- Water From Rock OutcropsDocument63 pagesWater From Rock OutcropsShiitake100% (1)

- Ferro Cement RoofDocument9 pagesFerro Cement RoofAr Aditya SharmaNo ratings yet

- Design Calculations For No-Head, Low-Head Waterwheels... by RuDocument2 pagesDesign Calculations For No-Head, Low-Head Waterwheels... by RuSPYDERSKILL100% (1)

- Introduction, Beam and SlabDocument6 pagesIntroduction, Beam and SlabNinie AzrinNo ratings yet

- Unit 1 CACMDocument34 pagesUnit 1 CACMRajha RajeswaranNo ratings yet

- Ques Bank Cacep Cie 2 Oct 2023Document30 pagesQues Bank Cacep Cie 2 Oct 2023Rajha RajeswaranNo ratings yet

- Athena 2023 SeptemberDocument70 pagesAthena 2023 SeptemberRajha RajeswaranNo ratings yet

- CON QUIZ Q Bank-2 NewDocument5 pagesCON QUIZ Q Bank-2 NewRajha RajeswaranNo ratings yet

- QP 1 CPS 21CE321T CIE 2 3rd Yr Civil Engg. MAR 2024Document2 pagesQP 1 CPS 21CE321T CIE 2 3rd Yr Civil Engg. MAR 2024Rajha RajeswaranNo ratings yet

- Ferrocement Shell RoofDocument6 pagesFerrocement Shell RoofRajha Rajeswaran100% (2)

- Computer Applications in Construction ManagementDocument12 pagesComputer Applications in Construction ManagementRajha RajeswaranNo ratings yet

- Sample PatentDocument16 pagesSample PatentRajha RajeswaranNo ratings yet

- QP 2 CPS 21CE321T CIE 2 3rd Yr Civil Engg. MAR 2024Document2 pagesQP 2 CPS 21CE321T CIE 2 3rd Yr Civil Engg. MAR 2024Rajha RajeswaranNo ratings yet

- Velammal Destiny InvitationDocument8 pagesVelammal Destiny InvitationRajha RajeswaranNo ratings yet

- CIE 1 QP 2nd Set CTP BE Civil Engg 3rd Sem SEP 2023Document1 pageCIE 1 QP 2nd Set CTP BE Civil Engg 3rd Sem SEP 2023Rajha RajeswaranNo ratings yet

- Construction EquipmentDocument23 pagesConstruction EquipmentRajha RajeswaranNo ratings yet

- HUB QB Job Nov 17, 2018Document5 pagesHUB QB Job Nov 17, 2018Rajha RajeswaranNo ratings yet

- Ques Bank For Prelims GeoTech Quiz 2015Document11 pagesQues Bank For Prelims GeoTech Quiz 2015Rajha RajeswaranNo ratings yet

- CM Cie 1 QBDocument7 pagesCM Cie 1 QBRajha RajeswaranNo ratings yet

- CRANESDocument45 pagesCRANESRajha RajeswaranNo ratings yet

- Aug 18 Hour 48 SoM 1Document21 pagesAug 18 Hour 48 SoM 1Rajha RajeswaranNo ratings yet

- Civil Engg ObjectiveDocument30 pagesCivil Engg ObjectiveRajha RajeswaranNo ratings yet

- PoM AU QP Big MarksDocument13 pagesPoM AU QP Big MarksRajha RajeswaranNo ratings yet

- Functional Classification of RoadsDocument26 pagesFunctional Classification of RoadsRajha RajeswaranNo ratings yet

- Glass Bottle WallsDocument27 pagesGlass Bottle WallsHiwi Negash100% (1)

- Finance BoqDocument372 pagesFinance Boqrak77No ratings yet

- Le CorbusierDocument32 pagesLe CorbusierRiaverma VermaNo ratings yet

- Construction Estimating PROJECT 02Document5 pagesConstruction Estimating PROJECT 02notevale100% (3)

- Wigley 2 PDFDocument33 pagesWigley 2 PDFcosorio5No ratings yet

- Estimating and Costing 15072020Document54 pagesEstimating and Costing 15072020Najim PatelNo ratings yet

- Shear WallDocument4 pagesShear WallIsmail A IsmailNo ratings yet

- Msheireb Downtown Doha Catalogue 1Document72 pagesMsheireb Downtown Doha Catalogue 1Maryam AL GhafriNo ratings yet

- History Quiz 2.0Document3 pagesHistory Quiz 2.0Ria Frania Dela CruzNo ratings yet

- Large Building Fires and Subsequent Code ChangesDocument20 pagesLarge Building Fires and Subsequent Code ChangesPopa ConstantinNo ratings yet

- Computation of Cooling LoadDocument10 pagesComputation of Cooling LoadYancy BagsaoNo ratings yet

- 09 - BoardDocument4 pages09 - Boardakankshas06No ratings yet

- Proposed Concrete Design Mix by FilFirstDocument19 pagesProposed Concrete Design Mix by FilFirstjaymarNo ratings yet

- Architectural Interior (Pertinent Laws)Document66 pagesArchitectural Interior (Pertinent Laws)Rhomayne Triz LapuzNo ratings yet

- Stair DesignDocument7 pagesStair DesignRifat Bin KamalNo ratings yet

- Solarmotion CatalogDocument7 pagesSolarmotion CatalogTeodor BaniskiNo ratings yet

- Appendix 1-Precast Factory-Concept Layout Plan PDFDocument1 pageAppendix 1-Precast Factory-Concept Layout Plan PDFAkshay Wahal100% (1)

- False CeilingDocument23 pagesFalse CeilingZhwan Anwar100% (1)

- 2STOARIENDA A1-MergedDocument13 pages2STOARIENDA A1-MergedMark Rengie Azul100% (1)

- Jurnal Korosi BajaDocument13 pagesJurnal Korosi BajapublikgerNo ratings yet

- Section 01 PDFDocument1 pageSection 01 PDFRufielle PascualNo ratings yet

- Analysis of Thermal Comfort Enhancement Using Vernacular Architecture in Siwa Oasis, EgyptDocument23 pagesAnalysis of Thermal Comfort Enhancement Using Vernacular Architecture in Siwa Oasis, EgyptMichael EssamNo ratings yet

- Selectcitywalk - MALL CASE STUDYDocument2 pagesSelectcitywalk - MALL CASE STUDYsakshiNo ratings yet

- Horizontal Seismic Band in Masonry StructuresDocument2 pagesHorizontal Seismic Band in Masonry StructuresSantosh YadavNo ratings yet

- Learning From Peter Buchanan - The Big Rethink - K - ResumenDocument56 pagesLearning From Peter Buchanan - The Big Rethink - K - ResumenMariaNo ratings yet

- Chapter-2 Building DrawingDocument32 pagesChapter-2 Building DrawingIssack MattewNo ratings yet

- Portfolio Beatriz OrozcoDocument16 pagesPortfolio Beatriz OrozcobeaorozcovNo ratings yet

Ferrocement Water Tank Construction

Ferrocement Water Tank Construction

Uploaded by

Rajha Rajeswaran0 ratings0% found this document useful (0 votes)

120 views32 pagesThis document provides instructions for constructing a ferrocement tank in less than 3 sentences:

Ferrocement tanks are constructed by building a wire mesh frame, applying cement mortar in layers to form walls at least 2 inches thick, and constructing a domed roof using wood forms, rebar, wire mesh and more cement mortar before curing and finishing the tank.

Original Description:

Ferrocement

Original Title

Ferrocement Water Tank Construction

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides instructions for constructing a ferrocement tank in less than 3 sentences:

Ferrocement tanks are constructed by building a wire mesh frame, applying cement mortar in layers to form walls at least 2 inches thick, and constructing a domed roof using wood forms, rebar, wire mesh and more cement mortar before curing and finishing the tank.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

120 views32 pagesFerrocement Water Tank Construction

Ferrocement Water Tank Construction

Uploaded by

Rajha RajeswaranThis document provides instructions for constructing a ferrocement tank in less than 3 sentences:

Ferrocement tanks are constructed by building a wire mesh frame, applying cement mortar in layers to form walls at least 2 inches thick, and constructing a domed roof using wood forms, rebar, wire mesh and more cement mortar before curing and finishing the tank.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 32

INTRODUCTION:

• Ferro cement is a form of reinforced concrete using closely

spaced multiple layers of mesh and small diameter rods

completely infiltrated with mortar.

• Ferro-cement consists of wire meshes and cement mortar. It

was developed by P.L.Nervi , an Italian architect in 1940.

• Ferro cement is widely used due to the low self weight, lack

of skilled workers, no need of framework etc.

How to construct a ferrocement tank ?

->Plan and design the tank.

->Prepare the site and create a formwork.

->Install reinforcing bars and metal mesh inside the formwork.

->Mix and apply cement mortar in layers, allowing each layer to

partially set.

->Cure the tank by keeping it moist for at least a week.

->Demold the tank and finish the surface as needed.

->Optionally, apply a sealant for water resistance.

.

Cut the chicken wire/hexagonal

wire mesh using the wire cutters.

The tank size will dictate the

necessary sizes of the mesh.

Cut the electro-welded mesh using the

bolt cutters. The tank size will dictate

the necessary sizes of the mesh.

Lay the chicken wire and electro-

welded mesh flat to create layers. The

layering should be as follows: 2 layers

of chicken wire, 1 layer of electro-

welded mesh, 2 layers of chicken wire.

Using wire ties and the pliers,

fasten the flat layers of mesh

together.

Know that once the mesh layers are

securely fastened, roll one end of the

mesh to the other and attach the two

ends together using the wire ties. This

will create the circular body structure of

the tank walls

Stand the mesh frame upright on

the tank foundation and attach,

using the wire ties, the frame to

rebar protruding from the tank

foundation.

Tie the reinforcement wire near the top of

the mesh frame and connect the wire to

the ground. Be sure that the wire is in

tension. This will prevent the walls from

buckling during the construction and

concrete curing stages. Four

reinforcement wires around the perimeter

of the frame are sufficient.

Place scrap pipes as form placeholders

for the inflow, outflow, overflow, and

drainage pipe locations

Slap the concrete mortar onto the

outside of the mesh frame. The

mortar should be applied so that the

holes of the mesh are completely

filled.

Allow the mortar to cure

Repeat step 9 with the inside of the

mesh frame. Use a ladder when

climbing in and out of the tank

structure.

Allow the mortar to cure. Keep the

walls wet during the curing process.

Once all the mortar has been

applied, the walls will be about 2

inches (5.1 cm) thick.

Cut the wood boards so that one

edge is curved outward. This can be

done while the tank walls are curing.

The tank size will dictate the

necessary sizes of the forms.

Once the walls are fully cured, position the

wood beams inside the tank. One log will be the

center pole sticking up vertically from the center

of the foundation. Two logs will be cross bars

near to the top of the walls to support the

wooden roof forms. Additional vertical logs will

also be used to support the wooden roof forms;

these logs should be placed along the inside

circumference of the walls.

Nail the cut wood board forms to the

support poles. The wood will create

a domed roof form.

Nail the plywood sheets flat against

the wood board forms.

Leave one square space open in the

forms. This will provide the tank

lid opening.

Lay concentric circle of rebar on top of

the plywood sheets.

Tie supporting wires to the rebar

circles using wire ties. The

wires should run from the dome

center down to the base of the

roof.

Place and tie chicken wire mesh

to the supporting wires.

Slap concrete mortar mixture onto the roof

forms. Be sure that enough concrete gets below

the rebar circles.

Allow the concrete to cure. Keep the

concrete wet during this process.

Once the concrete has cured, enter

the tank through the open square

space.

Carefully remove the wood beams,

forms and plywood.

Paint the inside of the tank with

the waterproof sealant.

Install the square metal lid into

the open space of to roof.

Paint the walls and roof of the

ferrocement tank with any

desired color.

You might also like

- Concrete Exposure Classes A23.1-19Document7 pagesConcrete Exposure Classes A23.1-19Steven SebastianNo ratings yet

- WASH Evaluation Solar Powered Water Supply Systems Somalia 2016-003Document60 pagesWASH Evaluation Solar Powered Water Supply Systems Somalia 2016-003kooj diriye100% (1)

- Alternative Building Techniques: 5 Architects and Their ProjectsDocument39 pagesAlternative Building Techniques: 5 Architects and Their ProjectsOmveer KumarNo ratings yet

- Lintel ClassificationDocument6 pagesLintel ClassificationsravanNo ratings yet

- Dib83-04 Caltrans CMP Culvert Repair Practices Manual PDFDocument210 pagesDib83-04 Caltrans CMP Culvert Repair Practices Manual PDFmm0493440No ratings yet

- Question Bank - MCQ - LandscapeDocument16 pagesQuestion Bank - MCQ - LandscapeASWIN KUMAR N S70% (10)

- Bathroom Remodel ChecklistDocument2 pagesBathroom Remodel ChecklistSol Farahmand100% (1)

- Ferro Cement Water TankDocument42 pagesFerro Cement Water TankbenzzenhdNo ratings yet

- Tehnology of ConstructionDocument11 pagesTehnology of ConstructionZenaida VoiculetNo ratings yet

- Pre Stressed BeamsDocument127 pagesPre Stressed BeamsjaffnaNo ratings yet

- Tie BarsDocument18 pagesTie BarsKutty Mansoor100% (1)

- Unit-3 (FRP & Ferrocement)Document27 pagesUnit-3 (FRP & Ferrocement)Mohammed Imran100% (1)

- IDE Lec8 Canal LiningDocument65 pagesIDE Lec8 Canal LiningFortiter FysproNo ratings yet

- Fly Ash Soil BlocksDocument42 pagesFly Ash Soil Blocksrafilu100% (1)

- Low Cost ConstructionDocument14 pagesLow Cost Constructionkaushita banerjee100% (1)

- Advantages of Shell Structures PDFDocument3 pagesAdvantages of Shell Structures PDFNeven Ahmed HassanNo ratings yet

- Is 9901-1 PDFDocument12 pagesIs 9901-1 PDFJGD123No ratings yet

- Gabion Walls For Form and Function - Backwoods Home MagazineDocument6 pagesGabion Walls For Form and Function - Backwoods Home Magazinesuasponte2No ratings yet

- All CladdingDocument44 pagesAll CladdingalloytarungNo ratings yet

- Pole Barn Metal DetailsDocument52 pagesPole Barn Metal DetailsKurt Stailey100% (1)

- Structural Steel Reuse in ConstructionDocument12 pagesStructural Steel Reuse in ConstructionMuhammad MurtazaNo ratings yet

- Canal Design1Document18 pagesCanal Design1Santosh Kumar DasNo ratings yet

- Analytical Research On Ferrocement: Design, Strength and Servicibility AspectsDocument8 pagesAnalytical Research On Ferrocement: Design, Strength and Servicibility AspectsPiyush SharmaNo ratings yet

- Innovative Uses of House Lifting Techniq PDFDocument15 pagesInnovative Uses of House Lifting Techniq PDFPandi AnNo ratings yet

- Wood Shingles and ShakesDocument6 pagesWood Shingles and Shakesjack.simpson.changNo ratings yet

- Performance Evaluation of High Strength Concrete With Partial Replacement of Saw DustDocument10 pagesPerformance Evaluation of High Strength Concrete With Partial Replacement of Saw DustInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Part 4 2 RMCdamDocument38 pagesPart 4 2 RMCdamKremen Mitov100% (1)

- Installation of Ceramic Tile in Swimming PoolsDocument5 pagesInstallation of Ceramic Tile in Swimming PoolsTenaw AlamirewNo ratings yet

- Lintel and ArchesDocument58 pagesLintel and ArchesVarinder SinghNo ratings yet

- Unit - 2: Advanced Concrete and Composite ReinforcementDocument89 pagesUnit - 2: Advanced Concrete and Composite Reinforcementsanjay saravananNo ratings yet

- Air Raid Shelters at ST Luke's and Warstones Schools, WolverhamptonDocument25 pagesAir Raid Shelters at ST Luke's and Warstones Schools, WolverhamptondigitalpastNo ratings yet

- Repair of Underwater Concrete StructuresDocument5 pagesRepair of Underwater Concrete StructuresRaja babuNo ratings yet

- Sea Sand Replacement With Fine AggregateDocument40 pagesSea Sand Replacement With Fine AggregateBHAVANA MNo ratings yet

- DIY Paving PDF 31103601924Document4 pagesDIY Paving PDF 31103601924Laki RevellosNo ratings yet

- DM PH&SD P7 TG02 (Guidelines+for+Approval+of+Swimming+Pool+Plans)Document5 pagesDM PH&SD P7 TG02 (Guidelines+for+Approval+of+Swimming+Pool+Plans)jbonvierNo ratings yet

- Ferrocement Construction Technology and Its Applications PDFDocument20 pagesFerrocement Construction Technology and Its Applications PDFPranavaDart0% (1)

- Above-Ground Rainwater StorageDocument4 pagesAbove-Ground Rainwater StorageikaspuspasariNo ratings yet

- Some Innovative Steel StructuresDocument12 pagesSome Innovative Steel Structuresgurdan100% (2)

- Module 2 Pfrefab Components ComDocument86 pagesModule 2 Pfrefab Components ComAravinda NatikeriNo ratings yet

- Design, Manufacture and Test A Hydraulic Ram: ThesisDocument42 pagesDesign, Manufacture and Test A Hydraulic Ram: ThesisIrfan ShaikhNo ratings yet

- Radial WellsDocument44 pagesRadial Wellsidigiti100% (1)

- Hollow Slab / Concrete Beams MachineryDocument26 pagesHollow Slab / Concrete Beams Machineryprensoland100% (1)

- Soil Properties GuidlineDocument27 pagesSoil Properties GuidlineJulfikar KhanNo ratings yet

- Ce102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeDocument46 pagesCe102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeRomel BernardoNo ratings yet

- Sprayed ConcreteDocument27 pagesSprayed ConcreteSharanu PujariNo ratings yet

- Bamboo Space Frame Structures - Aug2012Document4 pagesBamboo Space Frame Structures - Aug2012Shriti DasNo ratings yet

- Build A Retaining WallDocument13 pagesBuild A Retaining WallAnonymous 1TTYYaNo ratings yet

- HB Assignment 2Document11 pagesHB Assignment 2Himanshu BishnoiNo ratings yet

- Fibre Reinforced ConcreteDocument6 pagesFibre Reinforced ConcreteFranklyn GenoveNo ratings yet

- Tipi Setup Catalog12 V6.0Document31 pagesTipi Setup Catalog12 V6.0victorNo ratings yet

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 pagesWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieNo ratings yet

- Monopole Mounts P70to88Document19 pagesMonopole Mounts P70to88robrebelNo ratings yet

- Auckland Soakhole Design Manual PDFDocument109 pagesAuckland Soakhole Design Manual PDFfrankmaggie850102No ratings yet

- FoundationDocument6 pagesFoundationAnonymous dK9Qi2XjNo ratings yet

- How I Built My Own Wind Turbine For My HouseDocument16 pagesHow I Built My Own Wind Turbine For My HouseAbu AsimNo ratings yet

- 1 Bridge Types and ClassificationsDocument65 pages1 Bridge Types and ClassificationsPraveen BhandariNo ratings yet

- Chapter 4 Roofs: Page 1 of Ch-4 A Lecture Note Compiled By: Er. Kishor ThapaDocument6 pagesChapter 4 Roofs: Page 1 of Ch-4 A Lecture Note Compiled By: Er. Kishor ThapaPratik Ghimire100% (1)

- Water From Rock OutcropsDocument63 pagesWater From Rock OutcropsShiitake100% (1)

- Ferro Cement RoofDocument9 pagesFerro Cement RoofAr Aditya SharmaNo ratings yet

- Design Calculations For No-Head, Low-Head Waterwheels... by RuDocument2 pagesDesign Calculations For No-Head, Low-Head Waterwheels... by RuSPYDERSKILL100% (1)

- Introduction, Beam and SlabDocument6 pagesIntroduction, Beam and SlabNinie AzrinNo ratings yet

- Unit 1 CACMDocument34 pagesUnit 1 CACMRajha RajeswaranNo ratings yet

- Ques Bank Cacep Cie 2 Oct 2023Document30 pagesQues Bank Cacep Cie 2 Oct 2023Rajha RajeswaranNo ratings yet

- Athena 2023 SeptemberDocument70 pagesAthena 2023 SeptemberRajha RajeswaranNo ratings yet

- CON QUIZ Q Bank-2 NewDocument5 pagesCON QUIZ Q Bank-2 NewRajha RajeswaranNo ratings yet

- QP 1 CPS 21CE321T CIE 2 3rd Yr Civil Engg. MAR 2024Document2 pagesQP 1 CPS 21CE321T CIE 2 3rd Yr Civil Engg. MAR 2024Rajha RajeswaranNo ratings yet

- Ferrocement Shell RoofDocument6 pagesFerrocement Shell RoofRajha Rajeswaran100% (2)

- Computer Applications in Construction ManagementDocument12 pagesComputer Applications in Construction ManagementRajha RajeswaranNo ratings yet

- Sample PatentDocument16 pagesSample PatentRajha RajeswaranNo ratings yet

- QP 2 CPS 21CE321T CIE 2 3rd Yr Civil Engg. MAR 2024Document2 pagesQP 2 CPS 21CE321T CIE 2 3rd Yr Civil Engg. MAR 2024Rajha RajeswaranNo ratings yet

- Velammal Destiny InvitationDocument8 pagesVelammal Destiny InvitationRajha RajeswaranNo ratings yet

- CIE 1 QP 2nd Set CTP BE Civil Engg 3rd Sem SEP 2023Document1 pageCIE 1 QP 2nd Set CTP BE Civil Engg 3rd Sem SEP 2023Rajha RajeswaranNo ratings yet

- Construction EquipmentDocument23 pagesConstruction EquipmentRajha RajeswaranNo ratings yet

- HUB QB Job Nov 17, 2018Document5 pagesHUB QB Job Nov 17, 2018Rajha RajeswaranNo ratings yet

- Ques Bank For Prelims GeoTech Quiz 2015Document11 pagesQues Bank For Prelims GeoTech Quiz 2015Rajha RajeswaranNo ratings yet

- CM Cie 1 QBDocument7 pagesCM Cie 1 QBRajha RajeswaranNo ratings yet

- CRANESDocument45 pagesCRANESRajha RajeswaranNo ratings yet

- Aug 18 Hour 48 SoM 1Document21 pagesAug 18 Hour 48 SoM 1Rajha RajeswaranNo ratings yet

- Civil Engg ObjectiveDocument30 pagesCivil Engg ObjectiveRajha RajeswaranNo ratings yet

- PoM AU QP Big MarksDocument13 pagesPoM AU QP Big MarksRajha RajeswaranNo ratings yet

- Functional Classification of RoadsDocument26 pagesFunctional Classification of RoadsRajha RajeswaranNo ratings yet

- Glass Bottle WallsDocument27 pagesGlass Bottle WallsHiwi Negash100% (1)

- Finance BoqDocument372 pagesFinance Boqrak77No ratings yet

- Le CorbusierDocument32 pagesLe CorbusierRiaverma VermaNo ratings yet

- Construction Estimating PROJECT 02Document5 pagesConstruction Estimating PROJECT 02notevale100% (3)

- Wigley 2 PDFDocument33 pagesWigley 2 PDFcosorio5No ratings yet

- Estimating and Costing 15072020Document54 pagesEstimating and Costing 15072020Najim PatelNo ratings yet

- Shear WallDocument4 pagesShear WallIsmail A IsmailNo ratings yet

- Msheireb Downtown Doha Catalogue 1Document72 pagesMsheireb Downtown Doha Catalogue 1Maryam AL GhafriNo ratings yet

- History Quiz 2.0Document3 pagesHistory Quiz 2.0Ria Frania Dela CruzNo ratings yet

- Large Building Fires and Subsequent Code ChangesDocument20 pagesLarge Building Fires and Subsequent Code ChangesPopa ConstantinNo ratings yet

- Computation of Cooling LoadDocument10 pagesComputation of Cooling LoadYancy BagsaoNo ratings yet

- 09 - BoardDocument4 pages09 - Boardakankshas06No ratings yet

- Proposed Concrete Design Mix by FilFirstDocument19 pagesProposed Concrete Design Mix by FilFirstjaymarNo ratings yet

- Architectural Interior (Pertinent Laws)Document66 pagesArchitectural Interior (Pertinent Laws)Rhomayne Triz LapuzNo ratings yet

- Stair DesignDocument7 pagesStair DesignRifat Bin KamalNo ratings yet

- Solarmotion CatalogDocument7 pagesSolarmotion CatalogTeodor BaniskiNo ratings yet

- Appendix 1-Precast Factory-Concept Layout Plan PDFDocument1 pageAppendix 1-Precast Factory-Concept Layout Plan PDFAkshay Wahal100% (1)

- False CeilingDocument23 pagesFalse CeilingZhwan Anwar100% (1)

- 2STOARIENDA A1-MergedDocument13 pages2STOARIENDA A1-MergedMark Rengie Azul100% (1)

- Jurnal Korosi BajaDocument13 pagesJurnal Korosi BajapublikgerNo ratings yet

- Section 01 PDFDocument1 pageSection 01 PDFRufielle PascualNo ratings yet

- Analysis of Thermal Comfort Enhancement Using Vernacular Architecture in Siwa Oasis, EgyptDocument23 pagesAnalysis of Thermal Comfort Enhancement Using Vernacular Architecture in Siwa Oasis, EgyptMichael EssamNo ratings yet

- Selectcitywalk - MALL CASE STUDYDocument2 pagesSelectcitywalk - MALL CASE STUDYsakshiNo ratings yet

- Horizontal Seismic Band in Masonry StructuresDocument2 pagesHorizontal Seismic Band in Masonry StructuresSantosh YadavNo ratings yet

- Learning From Peter Buchanan - The Big Rethink - K - ResumenDocument56 pagesLearning From Peter Buchanan - The Big Rethink - K - ResumenMariaNo ratings yet

- Chapter-2 Building DrawingDocument32 pagesChapter-2 Building DrawingIssack MattewNo ratings yet

- Portfolio Beatriz OrozcoDocument16 pagesPortfolio Beatriz OrozcobeaorozcovNo ratings yet