Professional Documents

Culture Documents

BP - Ageing Static

BP - Ageing Static

Uploaded by

nico.seymusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BP - Ageing Static

BP - Ageing Static

Uploaded by

nico.seymusCopyright:

Available Formats

Ageing on static equipment

Table of content

Containing

Erosion

equipment

Static

Corrosion Valves

equipment

Heating

Vibration

equipment

2 Ageing a practical guide

Static Equipment

1. Static equipment

Containment Heating Control

Piping Heat exchangers Valves

S Pressure vessels S Re boilers S Actuators

St Storage tanks Furnaces & Heaters St Safety/pressure valves

Sta Drums Sta Non return valves

Sta Reactors Sta Hydrant systems

ta i Filters ta i

Civil metal constructions

tci Flair systems

Sa tci

a

Metal constructions

Stci tci

ta

ci S Lighting poles ci

a

tc St c

ti ta

ci t

a

c ti

ci

c

4 Ageing a practical guide

Corrosion

2. Corrosion 1/7

The chemical or electrochemical

reaction between a material and its

environment that produces a

deterioration of the material and its

properties.

Metallic iron “wants” to become iron

ore again.

6 Ageing a practical guide

2. Corrosion 2/7

Material type

7 Ageing a practical guide

2. Generaal Corrosion 3/7

Atmospheric Corrosion

Carbon Dioxide

(Sweet) Corrosion

Hydrogen Sulphide

(Sour) Corrosion

Microbial

Corrosion

8 Ageing a practical guide

2. Generaal Corrosion rate 4/7

RL = (WT - MAWT) / CR

• RL = Remnant Life calculated from the last inspection

date

• WT = Actual Wall Thickness

• MAWT = Minimum Allowable Wall Thickness

• CR = Corrosion Rate

Corrosion Rate : 0.048 mm/year at rural sites

0.079 mm/year at marine sites

0.170 mm/year in some industrial atmospheres

0,003 mm/year driest atmosphere on earth

9 Ageing a practical guide

2. Localized Corrosion 5/7

Pitting corrosion

Crevice corrosion

Galvanic corrosion

Erosion

Corrosion

10 Ageing a practical guide

2. Localized Corrosion 6/7

Cavitational corrosion

Chloride Stress

Corrosion Cracking (SCC)

Hydrogen induced

cracking (HIC)

Corrosion Fatigue

Corrosion Under Insulation (CUI)

Buried Pipes

11 Ageing a practical guide

2. Corrosion Protection 7/7

• Coatings

• Cathodic protection: impressed currents

• Cathodic protection: sacrificial anodes

12 Ageing a practical guide

Erosion

3. Erosion

Erosion is the removal of the surface

of a material by abrasion

14 Ageing a practical guide

Vibration

4. Vibration

At resonance, stresses (vibrations) can

cause failure of components

16 Ageing a practical guide

Containing Equipment

5. Ageing mechanisms

Containment equipment can be subject to

• Corrosion

• Erosion

• Vibration

18 Ageing a practical guide

Heating Equipment

6. Ageing mechanisms

Heating equipment has the same ageing

mechanisms as containing equipment

• Corrosion

• Erosion

• Vibration

Temperature and chemical agents

accelerate the corrosion process

Heating and cooling cycles can produce

low cycle fatigue

20 Ageing a practical guide

Valves

7.1 Valves types

Valve categories by purpose Valve categories by operation

Isolating valves Manually

S Regulating valves S Pneumatical Actuated

St Relief valves St Electrical Actuated

Sta Non return or Check valves Sta

Sta Solenoid valves Pressure vessels ta

ta i ti

a

Valve tci

a categories by build up tci

tci ci

ci c

c

22 Ageing a practical guide

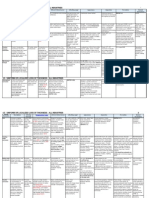

7.2 Ageing mechanisms 1/2

• Actuators are more prone to failure than valves

• Erosion can occure with abresive medium in the flow

• PRV’s have limited ageing but setpoint can deviate

23 Ageing a practical guide

7.2 Ageing mechanisms 2/2

In general valves will not be the limiting ageing factor

• Valves 100.000 to 1.000.000 cycles or 25 to 50 years

• Actuator 100.000 to 1.000.000 cycles or up to 40 years

• Check valves 1.000.000 cycles 50 years (20 to 25y overhaul)

• Solenoid valves 1 to 2 million continuous, 2 to 15 million

normal, 50 million heavy duty or 17 to 45 years

24 Ageing a practical guide

You might also like

- Juju Sundin, Sarah Murdoch-Juju Sundin's Birth Skills - Proven Pain-Management Techniques For Your Labour and Birth PDFDocument287 pagesJuju Sundin, Sarah Murdoch-Juju Sundin's Birth Skills - Proven Pain-Management Techniques For Your Labour and Birth PDFCamila BastosNo ratings yet

- Basic of CorrosionDocument67 pagesBasic of Corrosionkenzsugiyanto100% (1)

- Corrosion Mechanisms - Material Selection and Corrosion Control (Technip Italy)Document148 pagesCorrosion Mechanisms - Material Selection and Corrosion Control (Technip Italy)ah1525100% (4)

- Function, Structure, Operation of Engine Null (4JK1)Document36 pagesFunction, Structure, Operation of Engine Null (4JK1)jonathan100% (3)

- GS 08 50329 Hydrocracker Corrosion Control PDFDocument116 pagesGS 08 50329 Hydrocracker Corrosion Control PDFTerrance Badree100% (1)

- Bangalore Metallurgy in AIM BrochureDocument7 pagesBangalore Metallurgy in AIM Brochurebhavesh solankiNo ratings yet

- RCC CorrosionDocument125 pagesRCC CorrosionVINOTHINI R B.EdNo ratings yet

- Pipeline CorrosionDocument11 pagesPipeline Corrosioneng20072007No ratings yet

- NETRA Corrosion Control Dec 2016Document132 pagesNETRA Corrosion Control Dec 2016ankitgarg13100% (1)

- CorrosionDocument64 pagesCorrosionOmar Ezzat100% (1)

- SG-33 Electric Induction FurnaceDocument6 pagesSG-33 Electric Induction FurnaceDev PatelNo ratings yet

- CCW - Common Cooling System ProblemsDocument59 pagesCCW - Common Cooling System Problemszerocool86No ratings yet

- Evaluation of Steel and Tsa Coating in A Corrosion Under Insulation (Cui) EnvironmentDocument19 pagesEvaluation of Steel and Tsa Coating in A Corrosion Under Insulation (Cui) Environmentpapaya123No ratings yet

- Tp-Corrosion-Explique 240305 150304Document46 pagesTp-Corrosion-Explique 240305 150304hiepcon1216No ratings yet

- RCC Corrosion PDFDocument126 pagesRCC Corrosion PDFPreitee Ranjan PradhanNo ratings yet

- Corrosion Basic'sDocument58 pagesCorrosion Basic'sMayang Centya FebriaryNo ratings yet

- Pitting CorrosionDocument40 pagesPitting CorrosionRamin ShojaNo ratings yet

- Chapter 2-Metal CorrosionDocument75 pagesChapter 2-Metal Corrosionshenouda403No ratings yet

- Corrosion Control On Oil Pipelines - PPT Video Online Download2222Document10 pagesCorrosion Control On Oil Pipelines - PPT Video Online Download2222moheeNo ratings yet

- A Sacrificial AnodeDocument2 pagesA Sacrificial AnodeererNo ratings yet

- Practical Mitigation Procedures To Control Hydrogen-Related Damage During Production of Structural SteelsDocument12 pagesPractical Mitigation Procedures To Control Hydrogen-Related Damage During Production of Structural SteelsJJNo ratings yet

- Surface Production Operations 9Document61 pagesSurface Production Operations 9Сергей ВельдяксовNo ratings yet

- Corrosion in Offshore Wind Energy. A Major IssueDocument18 pagesCorrosion in Offshore Wind Energy. A Major IssueKenginNo ratings yet

- Galvanized Steel Specifiers GuideDocument20 pagesGalvanized Steel Specifiers GuideDan PascaruNo ratings yet

- Corr of Power Plant ComponentsDocument34 pagesCorr of Power Plant ComponentsAnil Kumar TNo ratings yet

- Corrosion Mitigation of Tanks: Chrissy HendersonDocument36 pagesCorrosion Mitigation of Tanks: Chrissy Hendersontania jessica gonzales giraldoNo ratings yet

- Corrosion Cooling SystemsDocument12 pagesCorrosion Cooling SystemsQuốc Anh KhổngNo ratings yet

- ICCP CathelcoDocument74 pagesICCP CathelcoNemanja TrojkovićNo ratings yet

- Localised CorrosionDocument82 pagesLocalised CorrosionAnil Kumar TNo ratings yet

- Corrosion of WeldmentsDocument174 pagesCorrosion of Weldments이선엽No ratings yet

- CorrosionDocument33 pagesCorrosionirfanlarikhotmailcom100% (1)

- T. Training Condition & Life Assessment Technique MPT Solution PDFDocument22 pagesT. Training Condition & Life Assessment Technique MPT Solution PDFHarianto ArieNo ratings yet

- Jotun CourseDocument76 pagesJotun CourseElhusseiny Fouda100% (1)

- Cooling Corrosion 01 2015Document92 pagesCooling Corrosion 01 2015Omar EscuderoNo ratings yet

- Hilti - Corrosion-Handbook - Tech Manual - 10 - 2015Document48 pagesHilti - Corrosion-Handbook - Tech Manual - 10 - 2015هدوء السماءNo ratings yet

- Kenny Corrosion StudiesDocument38 pagesKenny Corrosion StudiesOtaru kehindeNo ratings yet

- ISBScale Buster English2011Document8 pagesISBScale Buster English2011Constantin PopaNo ratings yet

- Reading List For New Corrosion Engineers in The Nuclear IndustryDocument15 pagesReading List For New Corrosion Engineers in The Nuclear IndustryAnonymous xyZH2OaUVNo ratings yet

- L2 - MRCS - Embedded Metal Corrosion - 2Document35 pagesL2 - MRCS - Embedded Metal Corrosion - 2Kaushal KumarNo ratings yet

- WRM Proceses - Copy (Autosaved)Document41 pagesWRM Proceses - Copy (Autosaved)Vikrant HanwatNo ratings yet

- Ts 22Document44 pagesTs 22ashuNo ratings yet

- 4.2 Mechanical and Metallurgical Damages - All IndustriesDocument4 pages4.2 Mechanical and Metallurgical Damages - All IndustriesKimi Konon100% (2)

- Evaluating Dielectric Conditionin SF6 Gas BreakersDocument18 pagesEvaluating Dielectric Conditionin SF6 Gas BreakersGabriel Zenarosa Lacsamana100% (2)

- Hilti Corrosion-Handbook EN PDFDocument48 pagesHilti Corrosion-Handbook EN PDFElenildo BarrosNo ratings yet

- Is 12560Document10 pagesIs 12560Srikanth VoletiNo ratings yet

- Welding and FabricationDocument54 pagesWelding and FabricationSungJun Park100% (1)

- C795-08 (2013) Standard Specification For Thermal Insulation For Use in Contact With Austenitic SDocument4 pagesC795-08 (2013) Standard Specification For Thermal Insulation For Use in Contact With Austenitic Snguyen100% (1)

- D807-14 Standard Practice For Assessing The Tendency of Industrial Boiler Waters To Cause Embrittlement (USBM1 Embrittlement Detector Method)Document6 pagesD807-14 Standard Practice For Assessing The Tendency of Industrial Boiler Waters To Cause Embrittlement (USBM1 Embrittlement Detector Method)astewayb_964354182No ratings yet

- TMS1285Document22 pagesTMS1285Nelson P. ColoNo ratings yet

- Corrosion: From Wikipedia, The Free EncyclopediaDocument4 pagesCorrosion: From Wikipedia, The Free EncyclopediapachecaquezadaNo ratings yet

- Corrosion PrinciplesDocument40 pagesCorrosion PrinciplesDinh Quoc HungNo ratings yet

- TMT ProcesesDocument39 pagesTMT ProcesesVikrant HanwatNo ratings yet

- NDT and CorrosionDocument21 pagesNDT and CorrosionPrakash100% (1)

- Corrosion and Degradation of MaterialsDocument22 pagesCorrosion and Degradation of MaterialsSiddharth Patel100% (1)

- Corrosion Final Term 2015 SessionDocument26 pagesCorrosion Final Term 2015 SessionHammad AhmadNo ratings yet

- CW Treatment by YogiDocument43 pagesCW Treatment by Yogiyogider palNo ratings yet

- A Holistic Model To Address Corrosion in Nuclear Power PlantsDocument44 pagesA Holistic Model To Address Corrosion in Nuclear Power PlantsHeramb TrifaleyNo ratings yet

- Metal Oxide Surge Arrester Application - PresentationDocument53 pagesMetal Oxide Surge Arrester Application - PresentationsulemankhalidNo ratings yet

- VOLTAMMETRY - Cathodic StrippingDocument10 pagesVOLTAMMETRY - Cathodic StrippingAndres Camilo Yasmo PerezNo ratings yet

- Section 3 - Corrosion - ProtectionDocument44 pagesSection 3 - Corrosion - ProtectionChris MedeirosNo ratings yet

- Galvanic CorrosionDocument20 pagesGalvanic CorrosionluisNo ratings yet

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document30 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkNo ratings yet

- Subsea Exercise No.6 PDFDocument16 pagesSubsea Exercise No.6 PDFEmmanuel Byensita100% (2)

- A Guide For Reduction and Disposal of Waste From Oil Refineries and Marketing InstallationsDocument40 pagesA Guide For Reduction and Disposal of Waste From Oil Refineries and Marketing InstallationsnikitaambeNo ratings yet

- JS1034-XX-F06-0001. A1Document107 pagesJS1034-XX-F06-0001. A1Pawan Gosavi100% (1)

- Itp - For Heat ExchangerDocument3 pagesItp - For Heat ExchangerSuraj ShettyNo ratings yet

- Aims and Obj of Financial RegulationDocument30 pagesAims and Obj of Financial RegulationIbrahim As'adNo ratings yet

- Meningitis Pathophysiology PDFDocument59 pagesMeningitis Pathophysiology PDFpaswordnyalupa100% (1)

- A Shawl For Anita: Lolita M. AndradaDocument11 pagesA Shawl For Anita: Lolita M. AndradaMelanie Mataga MagculangNo ratings yet

- Standard Operating Procedures Covid 19: CIDESCO Sections, CIDESCO Schools CIDESCO MembersDocument14 pagesStandard Operating Procedures Covid 19: CIDESCO Sections, CIDESCO Schools CIDESCO MembersShaji VkNo ratings yet

- Prodotti Manuali Documento 43Document16 pagesProdotti Manuali Documento 43whorne24No ratings yet

- Household Chores Multiple Choice Questionaire Picture Dictionaries - 76883Document1 pageHousehold Chores Multiple Choice Questionaire Picture Dictionaries - 76883Jayne Gomez ArenillaNo ratings yet

- Study - On GorfersDocument4 pagesStudy - On GorfersrashmiNo ratings yet

- Kalyan Sir - DPSPDocument6 pagesKalyan Sir - DPSPSuresh SuryaNo ratings yet

- Critical SkillsDocument5 pagesCritical SkillsJosiah MwashitaNo ratings yet

- Assignment Ahamadul Islam Ananna ID: 19304077 Section: 3 Course: ANT101 Fall 2020Document3 pagesAssignment Ahamadul Islam Ananna ID: 19304077 Section: 3 Course: ANT101 Fall 2020Ahamadul Islam OnonnoNo ratings yet

- CV Manat Ryan Hard NababanDocument1 pageCV Manat Ryan Hard NababanmanatNo ratings yet

- Corrguard Si PDFDocument18 pagesCorrguard Si PDFyolia16100% (1)

- Effects of Invasive Species Snails in Continental Aquatic Bodies of Pernambucano SemiaridDocument10 pagesEffects of Invasive Species Snails in Continental Aquatic Bodies of Pernambucano SemiaridVladut BratfaleanNo ratings yet

- Teknistae Sulakkeista Englanti PDFDocument156 pagesTeknistae Sulakkeista Englanti PDFJosué Miranda da SilvaNo ratings yet

- Stability Study of Cocoa Butter Body Scrub Formulated With Ground Cocoa Pod HuskDocument7 pagesStability Study of Cocoa Butter Body Scrub Formulated With Ground Cocoa Pod Huskudiwaluyo waluyoNo ratings yet

- Biomedical Waste ManagementDocument36 pagesBiomedical Waste ManagementAlice sylviya SamuelNo ratings yet

- Parle AgroDocument3 pagesParle AgroKumar GautamNo ratings yet

- Product Decors and Services BrochureDocument76 pagesProduct Decors and Services BrochureAleksandr LesnikNo ratings yet

- Bank Management: Dr. Rania Salem Department of FinanceDocument22 pagesBank Management: Dr. Rania Salem Department of FinanceDoha KashNo ratings yet

- Lab1 Heat RadiationDocument8 pagesLab1 Heat Radiationsarjan59No ratings yet

- Steelcrete PavementsDocument4 pagesSteelcrete Pavementsvinay rodeNo ratings yet

- G Ed Suc: Uide To The I OllegesDocument56 pagesG Ed Suc: Uide To The I OllegesZacNo ratings yet

- Nontyphoidal Salmonella: An Occupational Hazard For Clinical Laboratory WorkersDocument3 pagesNontyphoidal Salmonella: An Occupational Hazard For Clinical Laboratory WorkersYahia BerbouchiNo ratings yet