Professional Documents

Culture Documents

Manual Transmission Powerflow

Manual Transmission Powerflow

Uploaded by

kenyot1270 ratings0% found this document useful (0 votes)

13 views11 pagesThe document discusses how power flows through a manual transmission with 5 gears and reverse. It explains that in first gear, power flows from the input shaft to the counter shaft, where the first gear drives the first gear on the output shaft through the synchronizer clutch hub. Diagrams then show the detailed powerflow for each gear and reverse. It also describes the gear shift mechanism, including how the shift lever and forks are used to engage synchronizer sleeves and lock gears.

Original Description:

Original Title

MANUAL TRANSMISSION POWERFLOW

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses how power flows through a manual transmission with 5 gears and reverse. It explains that in first gear, power flows from the input shaft to the counter shaft, where the first gear drives the first gear on the output shaft through the synchronizer clutch hub. Diagrams then show the detailed powerflow for each gear and reverse. It also describes the gear shift mechanism, including how the shift lever and forks are used to engage synchronizer sleeves and lock gears.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

13 views11 pagesManual Transmission Powerflow

Manual Transmission Powerflow

Uploaded by

kenyot127The document discusses how power flows through a manual transmission with 5 gears and reverse. It explains that in first gear, power flows from the input shaft to the counter shaft, where the first gear drives the first gear on the output shaft through the synchronizer clutch hub. Diagrams then show the detailed powerflow for each gear and reverse. It also describes the gear shift mechanism, including how the shift lever and forks are used to engage synchronizer sleeves and lock gears.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 11

MANUAL TRANSMISSION POWERFLOW

Understanding the powerflow through a transmission helps

the technician in diagnosing complaints and determining the

proper repairs to be done. The following illustrations show

the typical powerflow through a five speed transmission.

For example, in first gear, power flows from the input shaft

and main drive gear to the counter shaft. First gear, on the

counter shaft, drives first gear on the output shaft. The first

gear is locked to the synchronizer clutch hub transmitting

power to the output shaft.

On the following three pages, in figures 3_14 through figure

3_19, the powerflow for 1st, 2nd, 3rd, 4th, 5th, and Reverse

are highlighted and traced through a transmission.

MANUAL TRANSMISSION POWERFLOW

MANUAL TRANSMISSION POWERFLOW

MANUAL TRANSMISSION POWERFLOW

MANUAL TRANSMISSION POWERFLOW

MANUAL TRANSMISSION POWERFLOW

MANUAL TRANSMISSION POWERFLOW

GEAR SHIFT MECHANISM

The gear shift lever and internal linkage allow the

transmission to be shifted through the gears. The shift lever is

mounted in the transmission extension housing and pivots on

a ball socket.

The shift fork shaft connects the shift lever to the shift forks. A

detent ball and spring prevent the forks from moving on their

own. The shift forks are used to lock and unlock the

synchronizer hub sleeve and are mounted on the shafts either

by bolts or roll pins.

The shift forks ride in the grooves of the synchronizer hub

sleeves. Shift forks contact the spinning synchronizer sleeve

and apply pressure to engage the gear. To reduce wear, the

steel or aluminum forks can have contact surfaces of

hardened steel, bronze, low friction plastic, or a nylon pad

attached to the fork.

GEAR SHIFT MECHANISM

After the sleeve has been positioned, there should

be very little contact between the fork and sleeve.

The fork is properly positioned by the detent. The

back taper of the hub sleeve splines and spline gear,

and gear inertia lock mechanism, keep it in mesh

during different driving conditions.

Holding a gear into mesh with the fork results in

rapid wear of the fork and hub sleeve groove. Wear

at the shift lever ball socket, shift fork shaft bushings,

and shift fork contact surfaces may cause the

synchronizer sleeve to be improperly positioned,

causing the sleeve to jump out of gear.

GEAR SHIFT MECHANISM

GEAR SHIFT MECHANISM

You might also like

- 2003 NV3500 Service ManualDocument41 pages2003 NV3500 Service Manuallilfroger98% (40)

- Manual Trans Overhaul Chevrolet S10Document11 pagesManual Trans Overhaul Chevrolet S10Maxi Sardi100% (1)

- Section 3 - Manual TransmissionsDocument29 pagesSection 3 - Manual TransmissionsBhushan Verma100% (2)

- Prestolite Starter MMDocument155 pagesPrestolite Starter MMleather_nun100% (2)

- The Service Manual For GearboxDocument96 pagesThe Service Manual For GearboxPeter Sanjaya100% (6)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

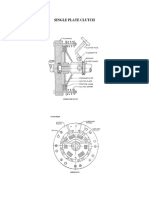

- Single Plate ClutchDocument4 pagesSingle Plate Clutchsaffrin0% (2)

- XJ250S Drawworks PDFDocument20 pagesXJ250S Drawworks PDFAnacleta GomezNo ratings yet

- 2012 Components Technical Manual UkDocument154 pages2012 Components Technical Manual UkBrummerNo ratings yet

- Hyundai HD78 Transmission M2S5, M3S5Document42 pagesHyundai HD78 Transmission M2S5, M3S5Bigfair HD78100% (1)

- Chapter Two Manual Transmission/TransaxleDocument13 pagesChapter Two Manual Transmission/TransaxleabasNo ratings yet

- Manual TransmissionDocument34 pagesManual TransmissionGabriel SabangNo ratings yet

- 3 Steering System UpdatedDocument98 pages3 Steering System UpdatedFitri9No ratings yet

- Tie Bolts/Rods: ArrangementDocument28 pagesTie Bolts/Rods: ArrangementSuhas KassaNo ratings yet

- 204-01 Front SuspensionDocument33 pages204-01 Front SuspensionMiguel AngelNo ratings yet

- ClutchDocument22 pagesClutchIsaiah LuleNo ratings yet

- Section 1.24 Gear Train and Engine TimingDocument20 pagesSection 1.24 Gear Train and Engine TimingLuis CastroNo ratings yet

- Automobile Clutch: Aim To Study and Prepare Report On The Constructional Details, Working Principles andDocument4 pagesAutomobile Clutch: Aim To Study and Prepare Report On The Constructional Details, Working Principles andசிவ சங்கர்No ratings yet

- Clutches and BrakesDocument10 pagesClutches and BrakesKhaloud Mahdi Al-JasmiNo ratings yet

- Lab 2Document13 pagesLab 2Fady KamilNo ratings yet

- 21me54 Mod-2Document29 pages21me54 Mod-2SrivatsaNo ratings yet

- ClutchDocument5 pagesClutchyudhisthar0110% (1)

- Technical Information About Steering Gears and Steering PumpsDocument37 pagesTechnical Information About Steering Gears and Steering PumpsVictor BalasNo ratings yet

- Steering System ComponentsDocument11 pagesSteering System Componentskeval patel0% (1)

- Galgotias University: Laboratory ManualDocument52 pagesGalgotias University: Laboratory ManualAgnivesh SharmaNo ratings yet

- SAA2E02E15100000Document27 pagesSAA2E02E15100000张业No ratings yet

- Automotive Starting SystemDocument28 pagesAutomotive Starting Systemkelvinthuita877No ratings yet

- Automotive (2) Lab: EXP1: ClutchesDocument7 pagesAutomotive (2) Lab: EXP1: ClutchesMohammad YahyaNo ratings yet

- Unit-2-Automobile EnggDocument23 pagesUnit-2-Automobile EnggPrashant BhumireddyNo ratings yet

- ZJ Trans&XferDocument356 pagesZJ Trans&Xferoğuzhan_tekceNo ratings yet

- AT6501 UwDocument132 pagesAT6501 UwAjithNo ratings yet

- Transmission and Drive Axle Hyster S135-155XL Repair ManualDocument25 pagesTransmission and Drive Axle Hyster S135-155XL Repair ManualArmando OrtaNo ratings yet

- Steering SystemsDocument8 pagesSteering SystemssurajcsioNo ratings yet

- Steering SystemDocument18 pagesSteering SystemUsama khanNo ratings yet

- What Does The Clutch Pressure Plate Do?Document10 pagesWhat Does The Clutch Pressure Plate Do?Kem Docenos Yam-ocNo ratings yet

- Andrew Ajirogi Ben Aldern John Odlum Johnny ChangDocument32 pagesAndrew Ajirogi Ben Aldern John Odlum Johnny Changshariefsm2No ratings yet

- Automotive TransmissionDocument146 pagesAutomotive TransmissionTony Neal100% (1)

- Multi-Cone Synchronizer SystemsDocument30 pagesMulti-Cone Synchronizer Systemsgrnflash100% (1)

- Automotive Transmission NewDocument147 pagesAutomotive Transmission NewhodvmkvecautoNo ratings yet

- Unit-III Transmission SysytemDocument168 pagesUnit-III Transmission Sysytemriyaz ahmedNo ratings yet

- Steering Gears Steering MechanismsDocument23 pagesSteering Gears Steering MechanismsthiagarajanNo ratings yet

- SSP 299 6 SP Manual Gearbox 08DDocument44 pagesSSP 299 6 SP Manual Gearbox 08DvasilealexandruNo ratings yet

- 04 Tie Rods or Tie BoltsDocument12 pages04 Tie Rods or Tie BoltsBhupender RamchandaniNo ratings yet

- 04 Tie Rods or Tie BoltsDocument12 pages04 Tie Rods or Tie BoltsrajishrrrNo ratings yet

- brakes-and-clutches-lecturer-noteDocument22 pagesbrakes-and-clutches-lecturer-noteashwini yewaleNo ratings yet

- Coupling Clutch BrakeDocument43 pagesCoupling Clutch BrakeSurjit Kumar Gandhi100% (1)

- Mechanics of Textile Machinery ContentDocument59 pagesMechanics of Textile Machinery ContentPARAMASIVAM SNo ratings yet

- Acdelco Steering and Suspension ManualDocument10 pagesAcdelco Steering and Suspension ManualfrostybergstromNo ratings yet

- Crane Control Equ PmentsDocument16 pagesCrane Control Equ PmentsslipformNo ratings yet

- 2004 Hyundai Sonata 2Document112 pages2004 Hyundai Sonata 2EJ EdgeNo ratings yet

- AT6501 (R-13) Notes PDFDocument131 pagesAT6501 (R-13) Notes PDFAashiq NawinNo ratings yet

- Jose Valen 10Document19 pagesJose Valen 10Meghan NielsenNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)