Professional Documents

Culture Documents

Dental Waxes and Base Plate Materials - 111150

Dental Waxes and Base Plate Materials - 111150

Uploaded by

Ron Kivasu0 ratings0% found this document useful (0 votes)

33 views25 pagesDental waxes and base plate materials are used in dentistry for various purposes. Waxes can be natural or synthetic and are classified based on their intended use as pattern, processing, or impression waxes. Pattern waxes like inlay and casting waxes are used to produce patterns for dental restorations. Processing waxes include boxing, utility, and sticky waxes used in laboratory procedures. Properties of waxes like melting range and flow are important for their manipulation. The lost wax technique uses waxes to create patterns that are lost through vaporization to produce dental castings.

Original Description:

Original Title

11. Dental Waxes and Base Plate Materials_111150

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDental waxes and base plate materials are used in dentistry for various purposes. Waxes can be natural or synthetic and are classified based on their intended use as pattern, processing, or impression waxes. Pattern waxes like inlay and casting waxes are used to produce patterns for dental restorations. Processing waxes include boxing, utility, and sticky waxes used in laboratory procedures. Properties of waxes like melting range and flow are important for their manipulation. The lost wax technique uses waxes to create patterns that are lost through vaporization to produce dental castings.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

33 views25 pagesDental Waxes and Base Plate Materials - 111150

Dental Waxes and Base Plate Materials - 111150

Uploaded by

Ron KivasuDental waxes and base plate materials are used in dentistry for various purposes. Waxes can be natural or synthetic and are classified based on their intended use as pattern, processing, or impression waxes. Pattern waxes like inlay and casting waxes are used to produce patterns for dental restorations. Processing waxes include boxing, utility, and sticky waxes used in laboratory procedures. Properties of waxes like melting range and flow are important for their manipulation. The lost wax technique uses waxes to create patterns that are lost through vaporization to produce dental castings.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 25

Dental waxes

&

Base Plate Materials

Dr. Mohamed Arnaout

Objectives

• Composition and origin

• Uses in dentistry

• Classification of wax in dentistry

• Properties

Composition and origin

• Waxes can be natural or synthetics:

a. Gums

b. Fats

c. Fatty acids

d. Oils

e. Natural and synthetic resins

f. Pigments

Composition and origin

• Natural waxes:

* Insects (beeswax)

* Mineral (petroleum and ceresin)

* Vegetable ( carnauba, candelila)

* Animal spermacitic wax

• Synthetic waxes

Uses in dentistry

In clinics In laboratories

Bite registration Boxing techniques

Alterations and adaptation Baseplate for complete

for impression trays and partial dentures

Direct waxing for cast Hold components before

restorations articulation

Indirect pattern for casting

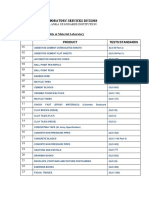

Classification of wax in dentistry

Pattern Processing Impression wax

wax wax

Inlay wax Boxing wax Corrective impression

wax

Casting Utility wax

wax Bite registration wax

Baseplate Sticky wax

wax

Pattern wax

• used to produce patterns for metal casting using the lost wax

technique

A. Inlay wax

– Type I: placed directly in the prepared tooth in the direct

waxing technique. This wax has a low melting range.

– Type II: melted on a die outside the mouth in the indirect

technique (more commonly used). These waxes are supplied

as pellets and sticks. They are blue and green in color. Hard,

medium, soft depending on melting range.

Pattern wax

B. Casting wax:

used to construct the

metal framework

for partial and

complete

dentures. Supplied

in sheets or

preformed shapes

Pattern wax

C. Baseplate wax:

Baseplate wax: sheets

of wax pink in color.

These sheets are

layered to produce

the form on which

denture teeth are

set

Processing wax

Boxing wax: used to

form the base

portion of a gypsum

model. Easily

manipulated at

room temperature.

Processing wax

Utility wax: also called periphery

wax, comes in ropes, and

easily manipulated at room

temperature. Used to adjust

impression trays, used to

cover sharp brackets and

wires in orthodontic

appliances, layered in sheets

for bite registration

Processing wax

Sticky wax: comes in orange

sticks that are hard and brittle

at room temperature. When

heated, become soft and

sticky. Used to adhere

components of metal,

gypsum, resin during

fabrication and repair.

Impression wax

• Corrective impression wax: used with other

impression materials for edentulous impressions,

to correct undercut areas. Flows at mouth

temperature.

• Bite registration: to produce wax bite registration

for articulation of models. Susceptible to

distortion, needs careful handling.

Manipulation

• Softened evenly in:

– Warm hands

– Dry heat

– Flame

• Added in layers into an object

• Should be invested within 30 minutes of carving

• Utility and boxing wax should remain dry to allow to stick when

manipulated.

• Should be stored at or slightly below room temperature

Properties

1. Melting range: a range of temperatures at which each

component of the wax will start to soften and then

flow. The operator can control the viscosity of wax by

controlling temperature.

2. Flow: is the movement of the wax as molecules slip

over each other. Melting range and flow of the wax are

important in wax manipulation by operator. E.g. bite

registration wax

Properties

Properties

3. Excess residue: for the sake of accuracy in the

object produced, if excess residue remains after

melted wax is removed, inaccuracies may occur.

(lost wax technique procedure)

Properties

4. Dimensional change: waxes expand when heated,

contract when cooled. Thermal expansion of waxes is

highest among dental materials. This property is

important especially for pattern waxes (e.g. inlay wax).

How:

– If wax is heated well beyond melting range or

unevenly, unacceptable expansion occurs.

– If wax is allowed to stand for a long time, the release

of residual stresses will lead to dimensional changes

and inaccuracies. This is why pattern wax should be

invested within 30 minutes of carving.

Lost wax technique

1. An impression of the preparation is taken and poured into

high strength stone to form a die.

2. Wax pattern is carved

3. Wax or plastic sprue is attached to pattern

4. Pattern and sprue are encased in investment ring, into which

investment gypsum is poured

5. Once investment sets, wax pattern and sprue are heated in a

burnout oven, causing wax and sprue to vaporize (lost wax),

leaving an impression of wax pattern in the empty case

Lost wax technique

6. Molten metal is poured through the empty channel

formed by sprue, into the empty wax pattern

space.

7. Metal cools, sprue removed, casting cleaned and

polished and now ready for cementation

Lost wax technique

Thank U

You might also like

- Strongcalc (Basic) : Blue Inputs (Edit These)Document51 pagesStrongcalc (Basic) : Blue Inputs (Edit These)Edward van doornNo ratings yet

- BOLESA Residence - Architectural SpecificationDocument18 pagesBOLESA Residence - Architectural SpecificationMarilou Basallo100% (1)

- Libro de Cera Del Japones AzulDocument142 pagesLibro de Cera Del Japones Azulminesponce100% (5)

- The Conventional Lathe Evolution: New Generation SCDocument18 pagesThe Conventional Lathe Evolution: New Generation SCIbrahim AzhariNo ratings yet

- Dental WaxesDocument32 pagesDental Waxesjohn mwambuNo ratings yet

- Waxes 1bdsDocument27 pagesWaxes 1bdsPreeti AgarwalNo ratings yet

- Dental Waxes Dental WaxesDocument29 pagesDental Waxes Dental WaxesSaurabh PawarNo ratings yet

- Dental WaxesDocument28 pagesDental WaxesMarios Tsakiridis0% (1)

- Dental Waxes Lec.12Document21 pagesDental Waxes Lec.12diyarberwari15No ratings yet

- Wax PatternDocument34 pagesWax PatternMariam SherifNo ratings yet

- Dental WaxesDocument28 pagesDental Waxesakashj20650% (2)

- Waxes: by DR Samreen Ahmed Dept of Dental MaterialsDocument8 pagesWaxes: by DR Samreen Ahmed Dept of Dental MaterialsHamza NadeemNo ratings yet

- Dental WaxDocument63 pagesDental WaxNavya AnilNo ratings yet

- Dental WaxfinalDocument80 pagesDental WaxfinalSimoun FeirNo ratings yet

- Dental WaxesDocument24 pagesDental Waxesمحمود ألاهدلNo ratings yet

- Dental WaxDocument29 pagesDental WaxSaurabh PawarNo ratings yet

- Inlay Casting Waxes & Wax Pattern FabricationDocument71 pagesInlay Casting Waxes & Wax Pattern FabricationMehak AryaNo ratings yet

- 13 WaxDocument67 pages13 WaxHadil AltilbaniNo ratings yet

- Dental MaterialsDocument31 pagesDental MaterialsRiz QianNo ratings yet

- Wax PatternDocument60 pagesWax PatternRosa GhahremaniNo ratings yet

- Dental WaxesDocument28 pagesDental Waxesk224299 Muhammad Sarim ShahNo ratings yet

- Dental Waxes: Dr. Archana Vyas Dept. of ProsthodonticsDocument33 pagesDental Waxes: Dr. Archana Vyas Dept. of ProsthodonticsAyaNo ratings yet

- Dental Waxes: Prosthodontics Assignment Bds 1St Year Roll Number-24Document4 pagesDental Waxes: Prosthodontics Assignment Bds 1St Year Roll Number-24Afnan AzadNo ratings yet

- Dental Waxes IOzcan Keyps PDFDocument35 pagesDental Waxes IOzcan Keyps PDFışıl özcan100% (1)

- Wa0004.Document32 pagesWa0004.Aisha samreenNo ratings yet

- Dental WaxesDocument60 pagesDental WaxesHarold MangaNo ratings yet

- L7 WaxDocument5 pagesL7 WaxAaaNo ratings yet

- Wax PatternDocument60 pagesWax Patternmustafa100% (1)

- 13 WaxDocument67 pages13 Waxak4sevenNo ratings yet

- Dental WaxesDocument49 pagesDental Waxeschoudharyishita163No ratings yet

- Dental Wax Yr3 1Document54 pagesDental Wax Yr3 1natchaya thitivarapornNo ratings yet

- Dental Materials PresentaionDocument21 pagesDental Materials Presentaionhamzawork106No ratings yet

- Dental WaxesDocument82 pagesDental WaxesVimalKumar100% (1)

- Dental WaxesDocument39 pagesDental WaxesJAYASURYA GOVINDARAJNo ratings yet

- Dental WaxesDocument7 pagesDental WaxesNurul IzzatiNo ratings yet

- Dental Material - MikeDocument22 pagesDental Material - MikeMike LimNo ratings yet

- 8 Dental WaxesDocument36 pages8 Dental Waxes刘雨樵No ratings yet

- Dental WaxesDocument75 pagesDental Waxesamayasudheeshkumar71No ratings yet

- DentalwaxesDocument56 pagesDentalwaxesnandhini2k23No ratings yet

- Seminar On WaxesDocument27 pagesSeminar On Waxesdrreba100% (2)

- Investment CastingDocument14 pagesInvestment CastingAkshaj NevgiNo ratings yet

- Casting Procedures: DR - Abhijit.Pallewar Dept of Conservative Dentistry & EndodonticsDocument82 pagesCasting Procedures: DR - Abhijit.Pallewar Dept of Conservative Dentistry & EndodonticsPavithra balasubramaniNo ratings yet

- Af Chapter 4 Waxes by DR Asad FarooqDocument51 pagesAf Chapter 4 Waxes by DR Asad FarooqGareth Bale100% (1)

- Wax Pattern: Type 1 (Medium Direct IntraoralDocument11 pagesWax Pattern: Type 1 (Medium Direct IntraoralMustafa SaßerNo ratings yet

- Dental WaxesDocument46 pagesDental WaxesAyu SawitriNo ratings yet

- Dental WaxesDocument18 pagesDental WaxesrajaniNo ratings yet

- Inlay Casting Wax-BDS II Year-31!12!14Document53 pagesInlay Casting Wax-BDS II Year-31!12!14Jihan CamilleNo ratings yet

- Models For Prosthodontics - Boxing-In Impressions: Dr/Ebrahim Al ShamiDocument12 pagesModels For Prosthodontics - Boxing-In Impressions: Dr/Ebrahim Al Shamiماجد هاديNo ratings yet

- Waxes: Dental Materials Assis. Prof. Dr. Ibrahim AlfahdawiDocument9 pagesWaxes: Dental Materials Assis. Prof. Dr. Ibrahim Alfahdawiزهراء فاضل اجبير فعيلNo ratings yet

- Fixed ProsthodonticsDocument21 pagesFixed ProsthodonticsnseraldenNo ratings yet

- Casting ProcedureDocument37 pagesCasting ProceduretaosifhasanshahidNo ratings yet

- Dental WaxesDocument23 pagesDental Waxesdrgayen6042100% (1)

- 4 Record Bases by FaryalDocument35 pages4 Record Bases by FaryalIslam ul haqNo ratings yet

- Jordan University For Science and TechnologyDocument3 pagesJordan University For Science and TechnologyTasneem HamdanNo ratings yet

- Waxes in DentistryDocument3 pagesWaxes in Dentistryloulwa76No ratings yet

- Record Bases & Occlusion RimsDocument34 pagesRecord Bases & Occlusion RimsmariahashrafNo ratings yet

- Die-Materials classEDITDocument45 pagesDie-Materials classEDITSatya AsatyaNo ratings yet

- Viral Hepatitis Breakthrough by SlidesgoDocument18 pagesViral Hepatitis Breakthrough by SlidesgoMohammed HassanNo ratings yet

- Waxes in Dentistry: PRESENTED BY: Dr. Pragya SaranDocument75 pagesWaxes in Dentistry: PRESENTED BY: Dr. Pragya SaranAllan JosephNo ratings yet

- Non Elastic ImpressionDocument65 pagesNon Elastic ImpressionAbdelruhman SobhyNo ratings yet

- Dental Waxes and InlayDocument5 pagesDental Waxes and InlayJEANASHLEY PUNZALAN0% (1)

- The Nail technician’s Career Guide - The blueprint to a successful nail salon businessFrom EverandThe Nail technician’s Career Guide - The blueprint to a successful nail salon businessNo ratings yet

- Abrasive Specification No.: SSPC: The Society For Protective CoatingsDocument3 pagesAbrasive Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- Activity 6890Document3 pagesActivity 6890Raymond Gicalde RementillaNo ratings yet

- Quality Control Flow Diagram of FBE CoatingDocument4 pagesQuality Control Flow Diagram of FBE CoatingOmar WardehNo ratings yet

- SEPL Product CatalogDocument16 pagesSEPL Product CatalogPawan SaraswatNo ratings yet

- Abstract of ASTM F738M 1997Document12 pagesAbstract of ASTM F738M 1997Jesse ChenNo ratings yet

- Ortho Class CatalogDocument49 pagesOrtho Class CatalogAbdul BasitNo ratings yet

- Epodux Zinc 62-208Document3 pagesEpodux Zinc 62-208Millennium PharmNo ratings yet

- Laboratory Services Division: Sri Lanka Standards InstitutionDocument4 pagesLaboratory Services Division: Sri Lanka Standards InstitutionAbcNo ratings yet

- MEPLDocument35 pagesMEPLMegamet Engineers Pvt. Ltd.No ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification SheetMohamed NouzerNo ratings yet

- TS - 016A - Temporary - Cathodic - Protection - 24.07.2020 - R-1Document24 pagesTS - 016A - Temporary - Cathodic - Protection - 24.07.2020 - R-1Aashish Moyal100% (1)

- Types of Carbon Steel and Their PropertiesDocument4 pagesTypes of Carbon Steel and Their Propertiesahmed ezwaiNo ratings yet

- A Study of Erosion Wear Behavior of Inconel-718 Nickel-Based Superalloy at Different Impingement AnglesDocument10 pagesA Study of Erosion Wear Behavior of Inconel-718 Nickel-Based Superalloy at Different Impingement Anglesppic.gapallanNo ratings yet

- Type Approval Certificate: Nord-Lock ABDocument4 pagesType Approval Certificate: Nord-Lock ABbladdeeNo ratings yet

- Knauf AQUAPANEL Exterior Ceiling System PDFDocument20 pagesKnauf AQUAPANEL Exterior Ceiling System PDFBHINEKA ENGINEERINGNo ratings yet

- Casting 1Document64 pagesCasting 1henokzewduNo ratings yet

- Cd12-24 RPF Hardware List FullDocument1 pageCd12-24 RPF Hardware List FullinayahNo ratings yet

- Dynamic transformation of α → β titanium at temperatures below the β -transus in commercially pure titaniumDocument4 pagesDynamic transformation of α → β titanium at temperatures below the β -transus in commercially pure titaniumLucas SerenaNo ratings yet

- Central Components Mfg. Company ProfileDocument6 pagesCentral Components Mfg. Company Profilewebmaster5813No ratings yet

- Is 2629Document23 pagesIs 2629Abhishek KaliaNo ratings yet

- WELD-A Welding Guide For Beginners - Beginner Welding GuideDocument11 pagesWELD-A Welding Guide For Beginners - Beginner Welding GuidepeterNo ratings yet

- Metco SF Alum. Wire 10-009Document3 pagesMetco SF Alum. Wire 10-009Remco Van Den BergNo ratings yet

- Northern Railway Jagadhri Workshop Auction ...Document121 pagesNorthern Railway Jagadhri Workshop Auction ...mitzz39No ratings yet

- SECT051223 Structural SteelDocument19 pagesSECT051223 Structural SteelTewodros TeferaNo ratings yet

- For Product Analysis of Steel Castings (: IS:6601 - 1987 I Permissible Deviations in Chemical CompositionDocument3 pagesFor Product Analysis of Steel Castings (: IS:6601 - 1987 I Permissible Deviations in Chemical Compositionrohan sharmaNo ratings yet

- 38 TabletDedusterModelTD2200 0Document2 pages38 TabletDedusterModelTD2200 0Satyam MadameNo ratings yet

- En 286-1Document96 pagesEn 286-1Onur oskay SaatçiNo ratings yet