Professional Documents

Culture Documents

Dowel Joint

Dowel Joint

Uploaded by

eyadianoofekry0 ratings0% found this document useful (0 votes)

4 views2 pagesmethod on how dowel joints are made

Original Title

DOWEL JOINT

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmethod on how dowel joints are made

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

4 views2 pagesDowel Joint

Dowel Joint

Uploaded by

eyadianoofekrymethod on how dowel joints are made

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 2

DOWEL

JOINT

How to make a dowl joint? Method 2:

How to make a dowl joint? Method 1:

One method of making dowel joints is to use Another method of making a dowel joint is to use a

marking tools known as dowel centers.. If doweling jig. This dowel jig will fit over a workpiece,

clamp into place, and guide the drill bit into the

they’re off by as much as 1/16th of an inch,

wood. The user can then transfer the jig onto

the joint might not work. The cylinder fits another workpiece and drill the corresponding

inside a drilled hole while the pin marks the holes. Because these jigs guide the drill bit, a drill

location of another. With careful alignment, press isn’t necessary. A sharp brad point bit, a

the user can push this pin into the surface of combination square, and a power drill will do the

the mating board, leaving a mark for a trick.

corresponding hole. The user can then drill It’s possible to create a dowel

the other hole and form the joint. Other than joint without dowel centers or

a combination square, sharp brad-point drill a doweling jig, but it takes

bits, and a drill (though a drill press is better), painfully exact layout and a

dowel centers are all that’s required. very steady, straight drilling

Step 1 Step 2 Step 3 Step 4 Step 5

Lay out the Dowel Clamp the Doweling Drill the Hole Test Fit the Joint Glue and Clamp

Locations

Jig in Place the Joint

The first step to making a Slide the doweling jig over Choose the drill bit that Before final assembly, it’s critical that

dowel joint is to lay out the the workpiece. All jigs matches the diameter of the you test fit the joint (known as dry

Squeeze a bit of

dowel locations. Place the

have reference markers dowels you intend to use and fitting). It should be snug but shouldn’t wood glue into the

two pieces of wood next to

each as if they’re already that you can use to align clamp it in your drill. Most require force, and the dowels should holes. Insert the

assembled (form the them. Carefully align the jigs have depth gauges that reach into each board sufficiently. The dowels into one

corner). Be sure that the reference marker with you can set to prevent from joint should also be flush and tight

horizontal piece (the rail) one of the lines drawn in drilling too deeply, but you without gaps, and dowels shouldn’t be board before

butts up to the vertical piece sliding the two

the last step and clamp can also use a piece of visible.

(the stile). Holding the

combination square the jig into place. For jigs masking tape wrapped If you drilled too deeply, cut a small plug boards together.

approximately 1/2-inch with multiple holes, be around the bit as the marker. off of a spare dowel and place it in the

down from the end of the sure you’re lining up the With the depth set, place the hole. If you didn’t drill deep enough, set

Use clamps to hold

stile, draw a line across the jig with the correct hole. bit in the appropriate guide, up the jig and drill deeper. There needs the joint together

stile and onto the rail with a

pencil. Move the

squeeze the drill’s trigger, to be a little bit of room in the end of until it dries.

combination square down and drill the hole. each hole for glue, but not so much that

one inch and draw another the dowel slides around sloppily.

line. These lines represent

You might also like

- Kumiko Jigs Japanese Woodworking PDFDocument9 pagesKumiko Jigs Japanese Woodworking PDFJaime Montiel100% (1)

- Woodsmith Rocking Horse PlansDocument11 pagesWoodsmith Rocking Horse Planscrm102bNo ratings yet

- D300 Mixer Parts Catalog F16971 (05-20)Document32 pagesD300 Mixer Parts Catalog F16971 (05-20)Eduardo TeslaNo ratings yet

- Step by Step Jewelry WorkshopDocument8 pagesStep by Step Jewelry WorkshopInterweave68% (31)

- I. OBJECTIVES • Identifying appropriate hand tools • Selecting appropriate hand tools II. SUBJECT MATTER Topic: USE OF HANDTOOLS Reference: CONSUMER ELECTRONICS SERVICING LM pp.4-14 CONSUMER ELECTRONICS SERVICING TG p. 12 III. PROCEDURE A. Pre-Activities Motivation: The teacher will show the students a video presentation of the concept of hand tools Presentation: The teacher will present the lesson for today: Use of Hand tools B. Activity Proper: The class will be divided into six groups .The groups will be given tools, discuss the tools in the group and identify them if the tool belongs to Driving Tools, Soldering Tools, Splicing Tools, Boring Tools, Cutting Tools, Auxiliary Tools. . Then, a representative from each group will explain why the given tool belongs to the kind of basic tools. C. Analysis: Let the students draw/illustrate the different tools with their functions. D. Abstraction: The teacher will show again a tool and ask the students to eDocument3 pagesI. OBJECTIVES • Identifying appropriate hand tools • Selecting appropriate hand tools II. SUBJECT MATTER Topic: USE OF HANDTOOLS Reference: CONSUMER ELECTRONICS SERVICING LM pp.4-14 CONSUMER ELECTRONICS SERVICING TG p. 12 III. PROCEDURE A. Pre-Activities Motivation: The teacher will show the students a video presentation of the concept of hand tools Presentation: The teacher will present the lesson for today: Use of Hand tools B. Activity Proper: The class will be divided into six groups .The groups will be given tools, discuss the tools in the group and identify them if the tool belongs to Driving Tools, Soldering Tools, Splicing Tools, Boring Tools, Cutting Tools, Auxiliary Tools. . Then, a representative from each group will explain why the given tool belongs to the kind of basic tools. C. Analysis: Let the students draw/illustrate the different tools with their functions. D. Abstraction: The teacher will show again a tool and ask the students to eSherwin Cayetano58% (12)

- 2020 WLAC - Tech Scoresheet - SmifinalsDocument1 page2020 WLAC - Tech Scoresheet - SmifinalsTeam 1No ratings yet

- Figure #2: The Parts For The Drilling Jig After Cutting To SizeDocument7 pagesFigure #2: The Parts For The Drilling Jig After Cutting To SizeEricsNo ratings yet

- Drill TechniquesDocument5 pagesDrill TechniquesJoaquín Capella CallavedNo ratings yet

- Three Easy Woodworking Jigs (Popular Woodworking)Document8 pagesThree Easy Woodworking Jigs (Popular Woodworking)Bozidar Vasiljevic100% (3)

- Snake DidgeridooDocument19 pagesSnake DidgeridooCesar Ojeda SaldivarNo ratings yet

- Pocket Hole JoineryDocument5 pagesPocket Hole JoineryJessica Sanders100% (3)

- Wood Joints (May 11, 2023)Document5 pagesWood Joints (May 11, 2023)leahlayon.iskolarNo ratings yet

- Human Arts - Hombre Que Llora Manual - AdornoDocument12 pagesHuman Arts - Hombre Que Llora Manual - Adornoyujraroberto4No ratings yet

- Human Arts - Hombre Atleta Manual - AdornoDocument12 pagesHuman Arts - Hombre Atleta Manual - Adornoyujraroberto4No ratings yet

- Car Case ConstructionDocument7 pagesCar Case ConstructionAnonymous QJ5j94luLmNo ratings yet

- All-Star Router Jigs: Make Your Tool A Multi-Tasker With This Problem-Solving ArsenalDocument7 pagesAll-Star Router Jigs: Make Your Tool A Multi-Tasker With This Problem-Solving ArsenalFernando AgudeloNo ratings yet

- Sunrise DovetailsDocument12 pagesSunrise DovetailsBobbyNo ratings yet

- 79 FT Latheless-Spindles FINALDocument4 pages79 FT Latheless-Spindles FINALAndrew LeeNo ratings yet

- Build Workbranch 1Document14 pagesBuild Workbranch 1cu-bisNo ratings yet

- WSS810 5CJTDocument15 pagesWSS810 5CJTroberto martinezNo ratings yet

- Hand Cut DovetailsFINALDocument6 pagesHand Cut DovetailsFINALMuhammet OfluoğluNo ratings yet

- Globe Puzzle: Assembly InstructionsDocument3 pagesGlobe Puzzle: Assembly InstructionsElia CF100% (1)

- Globe Puzzle InstruccionDocument3 pagesGlobe Puzzle InstruccionLizeth BaezNo ratings yet

- Pocket Hole JoineryDocument5 pagesPocket Hole Joineryjamboree_scribdNo ratings yet

- Q.A. How Would You Go About Turning A Twin Helix Like This?Document1 pageQ.A. How Would You Go About Turning A Twin Helix Like This?neko222No ratings yet

- Let's Make A Crokinole Board!: by GeekswoodshopDocument14 pagesLet's Make A Crokinole Board!: by GeekswoodshopManuel TorresNo ratings yet

- Woodcademy Folding Router Table Plans R2Document45 pagesWoodcademy Folding Router Table Plans R2Yamil PaladinoNo ratings yet

- A Benchtop BenchDocument2 pagesA Benchtop Benchcorneliu.modilca67% (3)

- Carpentry Job Report - Cross Lap JointDocument12 pagesCarpentry Job Report - Cross Lap JointMohammad Zahidul Karim83% (6)

- Woodworking Guide - Basic JoineryDocument6 pagesWoodworking Guide - Basic JoineryMrPaulCorcoran100% (1)

- Origami Arrowhead Bowl DiagramDocument8 pagesOrigami Arrowhead Bowl DiagramKanguru MuriukiNo ratings yet

- Art of Slow Dovetailing Through DovetailsDocument7 pagesArt of Slow Dovetailing Through DovetailsleeroyhaspoonNo ratings yet

- Woodworking TipsDocument13 pagesWoodworking TipsjahemscbdNo ratings yet

- Finger Joints: Fast and EasyDocument4 pagesFinger Joints: Fast and EasyIlberto FortunaNo ratings yet

- Trees Set 1Document8 pagesTrees Set 1EstherPerezExpositoNo ratings yet

- Drying RackDocument4 pagesDrying RackFahrudin NoorNo ratings yet

- Box Joinery 4.25ver8Document5 pagesBox Joinery 4.25ver8cajemarNo ratings yet

- Guide To Oboe Reedmaking 2021Document21 pagesGuide To Oboe Reedmaking 2021Katoka Felix100% (1)

- PerfecttapersDocument3 pagesPerfecttapersMarco FigueiredoNo ratings yet

- 7 Tips For Working With Plywood: © 2009 August Home Publishing CoDocument5 pages7 Tips For Working With Plywood: © 2009 August Home Publishing ColordkyoriNo ratings yet

- Box Joint Jig PlanDocument8 pagesBox Joint Jig PlanLarry MullinsNo ratings yet

- Paper BowsDocument3 pagesPaper BowsBev Wintle HeslinNo ratings yet

- 5 Shop Made Clamps - SSCDocument1 page5 Shop Made Clamps - SSCjuan olivaNo ratings yet

- CNT 0011130 02Document6 pagesCNT 0011130 02SonNo ratings yet

- Cutting Perfect TapersDocument3 pagesCutting Perfect Tapersgmand68100% (1)

- SIX-CANDLE CENTERPIECE - Woodsmith ShopDocument5 pagesSIX-CANDLE CENTERPIECE - Woodsmith ShopEricsNo ratings yet

- AR15 Forging ReceiverDocument105 pagesAR15 Forging ReceiverNO2NWO100% (12)

- 5hopnotes #85 - Router Table PDFDocument55 pages5hopnotes #85 - Router Table PDFpiedrahec100% (2)

- 5 Spline Miters JointDocument2 pages5 Spline Miters JointtomNo ratings yet

- Frog Chorus: Assembly Instructions: How To Play Assembly Instructions: Three A4 Sheets (PAGE01 To PAGE03)Document3 pagesFrog Chorus: Assembly Instructions: How To Play Assembly Instructions: Three A4 Sheets (PAGE01 To PAGE03)Rochi RodriguezNo ratings yet

- Whatnot Dish: The Ideal Gift BowlDocument5 pagesWhatnot Dish: The Ideal Gift BowlMarcos R. Hernández M.No ratings yet

- Napkin CaddyDocument10 pagesNapkin CaddyEmilian Baluta100% (2)

- Morning Dew PDFDocument2 pagesMorning Dew PDFGheorghe IliesNo ratings yet

- Morning Dew PDFDocument2 pagesMorning Dew PDFGheorghe IliesNo ratings yet

- Kusudama - Ball Diagrama (Makoto YmamguchiDocument2 pagesKusudama - Ball Diagrama (Makoto YmamguchiMarcelo HKonoNo ratings yet

- Spice Organizer Rack With Pull Out DrawersDocument22 pagesSpice Organizer Rack With Pull Out DrawersInsane HiNo ratings yet

- Crafts - Woodworking - Magazine - (Ebook) - Shopnotes #85 - Router Table +10 UpgradesDocument55 pagesCrafts - Woodworking - Magazine - (Ebook) - Shopnotes #85 - Router Table +10 Upgradespiedrahec100% (2)

- Pocket Hole JoineryDocument2 pagesPocket Hole JoineryFrancois Vaaltyn100% (1)

- Scrapwood Frame Saw: InstructablesDocument12 pagesScrapwood Frame Saw: InstructablesJasmine VaaltynNo ratings yet

- Military Mast: Problems and SolutionsDocument3 pagesMilitary Mast: Problems and Solutionsdod3007No ratings yet

- Loose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsDocument6 pagesLoose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsFausto Martin Vicente MoralesNo ratings yet

- Machine Cut DovetailsDocument4 pagesMachine Cut DovetailsFrancois VaaltynNo ratings yet

- Drilling Machine: Fierda Lestari Sarpangga Putri NRP 0516040128 D4 Teknik K3 Ppns (Lintas Jenjang)Document7 pagesDrilling Machine: Fierda Lestari Sarpangga Putri NRP 0516040128 D4 Teknik K3 Ppns (Lintas Jenjang)Fierda SarpanggaNo ratings yet

- Group 2 Tightening TorqueDocument3 pagesGroup 2 Tightening TorquerolandseNo ratings yet

- #Form Master List Alat Ukur - AllDocument18 pages#Form Master List Alat Ukur - AllAzis AsmawanNo ratings yet

- Learner'S Packet No. 4 Quarter 1: I. Introductory ConceptDocument4 pagesLearner'S Packet No. 4 Quarter 1: I. Introductory Conceptanna balmesNo ratings yet

- Ebook Commercial Refrigeration For Air Conditioning Technicians 3Rd Edition Wirz Solutions Manual Full Chapter PDFDocument46 pagesEbook Commercial Refrigeration For Air Conditioning Technicians 3Rd Edition Wirz Solutions Manual Full Chapter PDFVictoriaBrownwfjr100% (11)

- HAMMER STRENGTH EQUIPMENT ILBP-H ISO-Lateral Bench ...Document5 pagesHAMMER STRENGTH EQUIPMENT ILBP-H ISO-Lateral Bench ...Rida DahmounNo ratings yet

- M4 Internal Hex. Ø3.30: Implant SystemsDocument20 pagesM4 Internal Hex. Ø3.30: Implant SystemsNicolás MedinaNo ratings yet

- 3maintain - 32+45+53CDN - 20100205ADocument13 pages3maintain - 32+45+53CDN - 20100205APracetak GwkNo ratings yet

- Wet GrinderDocument1 pageWet GrinderMani KandanNo ratings yet

- Installing An External Bolt Stop/Release On A Remington 700Document10 pagesInstalling An External Bolt Stop/Release On A Remington 700M Poveda0% (1)

- Doc053.52.90451Document8 pagesDoc053.52.90451Morris PeregoNo ratings yet

- Price List SPC 2021Document15 pagesPrice List SPC 2021Nesa DjuricNo ratings yet

- FZ-BNC Slitter Rewinder Machine OperationDocument10 pagesFZ-BNC Slitter Rewinder Machine OperationYonas MuluNo ratings yet

- Check SheetDocument20 pagesCheck SheetMuis AnwarNo ratings yet

- All 3WH Spare Part Catalogue Excel File - SPCDocument471 pagesAll 3WH Spare Part Catalogue Excel File - SPCdubanjdssf100% (1)

- NPT Thread SizesDocument1 pageNPT Thread SizesVishal AryaNo ratings yet

- MODULE IN TLE 7 & 8 (Specialization-Cookery) First Grading/Week 3 Day 1Document6 pagesMODULE IN TLE 7 & 8 (Specialization-Cookery) First Grading/Week 3 Day 1Shi E LaNo ratings yet

- Refrigeration and Air Conditioning - 220308 - 155054Document13 pagesRefrigeration and Air Conditioning - 220308 - 155054Dhruvi PadmaniNo ratings yet

- Barrel Extension ThreadsDocument1 pageBarrel Extension Threadsblazerman3No ratings yet

- Local Control Box Wiring Diagram: Packman Horizontal Fire-Tube Steam BoilerDocument11 pagesLocal Control Box Wiring Diagram: Packman Horizontal Fire-Tube Steam BoilerBassilNo ratings yet

- Various Gear Finishing MethodsDocument9 pagesVarious Gear Finishing MethodsYoginderYadavNo ratings yet

- Chapter 11Document45 pagesChapter 11Fionna Lou M. CarandangNo ratings yet

- Questions: ST RD RDDocument4 pagesQuestions: ST RD RDjohnnyNo ratings yet

- Microtomy LectureDocument6 pagesMicrotomy LectureIsah Sitti0% (1)

- Apostila Rayk 01Document69 pagesApostila Rayk 01Rabelo JCNo ratings yet

- Biosafety Cabinet Model La2 4a e Class II TypeDocument12 pagesBiosafety Cabinet Model La2 4a e Class II TypedinniNo ratings yet

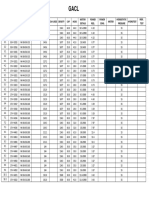

- Gacl Testing Data SheetDocument2 pagesGacl Testing Data SheetVIKASH RAINo ratings yet