Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsWelding Safety 2003

Welding Safety 2003

Uploaded by

mr. INCOGNITOCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You might also like

- Module 3 - Basic Safety Rules & Measures of Workplace Hazards (NAC)Document91 pagesModule 3 - Basic Safety Rules & Measures of Workplace Hazards (NAC)art031125100% (8)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Ag E860 MSDS enDocument6 pagesAg E860 MSDS enFernando CalderonNo ratings yet

- Uniflux™ System: Operating InstructionsDocument164 pagesUniflux™ System: Operating InstructionsOlger Renan PulamarinNo ratings yet

- 1466F Users Guide PowerBrush Premier PDFDocument16 pages1466F Users Guide PowerBrush Premier PDFDamien Rhys JonesNo ratings yet

- SAF-T-DATA™ GuideDocument23 pagesSAF-T-DATA™ GuideBoris ChicomaNo ratings yet

- Cyclohexanone MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesCyclohexanone MSDS: Section 1: Chemical Product and Company IdentificationNada NovindaNo ratings yet

- Welding Safety: by Usha Fire Safety Equipments (P) LTDDocument43 pagesWelding Safety: by Usha Fire Safety Equipments (P) LTDAkhilesh KagNo ratings yet

- Welding Safety: Cummins Southern Plains, LTDDocument32 pagesWelding Safety: Cummins Southern Plains, LTDSaras AgrawalNo ratings yet

- Welding Safety Hazards ExplainedDocument26 pagesWelding Safety Hazards Explainedsunilmathew4477No ratings yet

- Center of Excellence For Engineering National Welding Training CenterDocument48 pagesCenter of Excellence For Engineering National Welding Training CenterAmanuel HawiNo ratings yet

- Welding Safety HazardDocument32 pagesWelding Safety HazardjeonronbacurinNo ratings yet

- Welding Hazards AFSCME Fact SheetDocument11 pagesWelding Hazards AFSCME Fact SheetMuhammad Attaulla KhanNo ratings yet

- Welding SafetyDocument17 pagesWelding SafetySETIAJI WIBAWANo ratings yet

- Safety Measures in Pharmaceutical IndustriesDocument31 pagesSafety Measures in Pharmaceutical Industriesabdullah18oowNo ratings yet

- Work Instruction For Welder: Pre-Operation Check For SafetyDocument4 pagesWork Instruction For Welder: Pre-Operation Check For SafetyNnandkishoreNo ratings yet

- Weld Safe For StudentsDocument4 pagesWeld Safe For StudentsCharlyn PandaNo ratings yet

- Safety Precaution in Welding: Ashok Kumar Engineer Sales-Chennai D&H Secheron Electrodes PVT - LTDDocument36 pagesSafety Precaution in Welding: Ashok Kumar Engineer Sales-Chennai D&H Secheron Electrodes PVT - LTDPrakash RajNo ratings yet

- Welding Safety: Amit Gola Assistant Director (Safety)Document21 pagesWelding Safety: Amit Gola Assistant Director (Safety)Vishwash GoyalNo ratings yet

- JSA Detailed InfoDocument15 pagesJSA Detailed InfoGuptaNo ratings yet

- Surindra Engineering Co. LTD - Environmental Health & Safety DepartmentDocument70 pagesSurindra Engineering Co. LTD - Environmental Health & Safety DepartmentRushabh KapadiaNo ratings yet

- Safety Precautions in Welding - 0Document14 pagesSafety Precautions in Welding - 0Jaén García EnriquetaNo ratings yet

- 1 Welding SafetyDocument51 pages1 Welding SafetyAfshadNo ratings yet

- TYPES OF PPE YOU CAN USE TranslatorDocument3 pagesTYPES OF PPE YOU CAN USE TranslatorDiego Aarón AvendañoNo ratings yet

- Day 5 Apply-Safety-PracticesDocument16 pagesDay 5 Apply-Safety-Practicestrustfaith49No ratings yet

- Industrial Hazards: Thomas Shelby ID: 2063269060 Roll: 29Document9 pagesIndustrial Hazards: Thomas Shelby ID: 2063269060 Roll: 29Morshed AbirNo ratings yet

- Welding Safety Kemp Rev909Document64 pagesWelding Safety Kemp Rev909Mohammad AshpakNo ratings yet

- Plate MsdsDocument7 pagesPlate MsdsShawn ChiassonNo ratings yet

- WeldingDocument2 pagesWeldingGhodke ParmeshwarNo ratings yet

- Apply Safety PracticesDocument59 pagesApply Safety PracticesEugenio Jr. MatesNo ratings yet

- Arc Welding Safety PrecautionsDocument64 pagesArc Welding Safety Precautionsbarry bonzoNo ratings yet

- Written Report: Electrical Safety Hazards Negative Effects of Inhaling Fumes From Soldering Iron ComponentsDocument8 pagesWritten Report: Electrical Safety Hazards Negative Effects of Inhaling Fumes From Soldering Iron ComponentsAliceNo ratings yet

- Common 1 General Safety Precaution in WeldingDocument49 pagesCommon 1 General Safety Precaution in WeldingEgghead YTCNo ratings yet

- Safety in WeldingDocument3 pagesSafety in WeldingNAGABHUSHAN CPNo ratings yet

- Personal Protective Equipment: Office of Environmental, Health, & SafetyDocument70 pagesPersonal Protective Equipment: Office of Environmental, Health, & SafetyPedro SousaNo ratings yet

- Welding RulesDocument2 pagesWelding Rulesapi-626529020No ratings yet

- Smaw 12 Module 1Document7 pagesSmaw 12 Module 1Francis Rico Mutia RufonNo ratings yet

- Installation and Maintenance of ServicesDocument68 pagesInstallation and Maintenance of Servicesgodson.jacksonNo ratings yet

- Xti-160 Xti-161 DV: Operator ManualDocument16 pagesXti-160 Xti-161 DV: Operator ManualVicente SarmientoNo ratings yet

- Ppe American STDSDocument30 pagesPpe American STDSChetana HamsagarNo ratings yet

- 9-Welding and CuttingDocument19 pages9-Welding and CuttingAhmed AbbasNo ratings yet

- MIG-200L ManualDocument30 pagesMIG-200L ManualV-Man systemNo ratings yet

- Practical Work Book For Health Safety and EnvironmentDocument69 pagesPractical Work Book For Health Safety and EnvironmentAreejNo ratings yet

- Robin Rajan 18 Types of Ppe, Reapiratory and Non RespiratoryDocument22 pagesRobin Rajan 18 Types of Ppe, Reapiratory and Non Respiratoryrobin rajanNo ratings yet

- Final Health and SafetyDocument11 pagesFinal Health and SafetyMalka Melani JayaweeraNo ratings yet

- Freelander 2 BADocument6 pagesFreelander 2 BAJim LiebNo ratings yet

- 1 Electric Gas Welding SafetyDocument34 pages1 Electric Gas Welding SafetyPrincess Mae DesaculaNo ratings yet

- Safety Precautions in Welding Operation1Document11 pagesSafety Precautions in Welding Operation1sivaNo ratings yet

- ARC630Document90 pagesARC630VVan TanNo ratings yet

- Construction Safety - Part 3 (Ppe)Document27 pagesConstruction Safety - Part 3 (Ppe)Henry TuraldeNo ratings yet

- PosterDocument3 pagesPosterRahul NambiarNo ratings yet

- Lesson 08 Basic Occupational Safety and HealthDocument75 pagesLesson 08 Basic Occupational Safety and HealthJohn MaloneNo ratings yet

- Atig 400Document48 pagesAtig 400VVan TanNo ratings yet

- Mig 250c ManualDocument18 pagesMig 250c ManualBondan PratamaNo ratings yet

- Electrical InstallationDocument4 pagesElectrical Installationonchiriemmanuel891No ratings yet

- Shielded Metal Arc Welding NciiDocument8 pagesShielded Metal Arc Welding NciiElla MaeNo ratings yet

- Plasma YH-400 English ManualDocument29 pagesPlasma YH-400 English ManualOLVERACNCMAQUINAS EMPRESANo ratings yet

- SIF MTS300/400 Welder ManualDocument20 pagesSIF MTS300/400 Welder Manualsteven5140No ratings yet

- Kompakt 160Document180 pagesKompakt 160mihai37No ratings yet

- Tic MachineDocument33 pagesTic MachineDaniel AlmendarezNo ratings yet

- GMAW Facilitator GuideDocument42 pagesGMAW Facilitator GuideEng trk100% (1)

- Manual ATIG PACDocument82 pagesManual ATIG PACindo jasunNo ratings yet

- Laboratory Safety HEMA Chapter 2Document34 pagesLaboratory Safety HEMA Chapter 2Pam FajardoNo ratings yet

- 9 PpeDocument22 pages9 PpepokiningNo ratings yet

- Welding for Off-Road Beginners: This Book Includes - Welding for Beginners in Fabrication & Off-Road WeldingFrom EverandWelding for Off-Road Beginners: This Book Includes - Welding for Beginners in Fabrication & Off-Road WeldingRating: 5 out of 5 stars5/5 (2)

- (D-03573) DISTILLED WATER (D.M.Water)Document8 pages(D-03573) DISTILLED WATER (D.M.Water)sureshNo ratings yet

- Dyson DC32Document7 pagesDyson DC32philaskNo ratings yet

- TP6053 Catalago KohlerDocument70 pagesTP6053 Catalago KohlerOperaciones Max Diesel ProNo ratings yet

- Inverter 201 Ultra PFC ManualDocument44 pagesInverter 201 Ultra PFC ManualParadox UtopiaNo ratings yet

- R30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFDocument219 pagesR30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFdenix49No ratings yet

- 7 Hazardous LocationsDocument7 pages7 Hazardous LocationsBechir OuhibiNo ratings yet

- OBM Viscosifier - LiquidDocument3 pagesOBM Viscosifier - LiquidPranav DubeyNo ratings yet

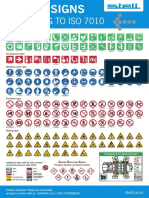

- According To Iso 7010: Safety SignsDocument1 pageAccording To Iso 7010: Safety SignsKirankumar PanchalNo ratings yet

- Complete 1000+ Error DetectingDocument159 pagesComplete 1000+ Error DetectingVikashNo ratings yet

- Es 120 - 252Document16 pagesEs 120 - 252ulvi ganjaliNo ratings yet

- ANSELL - Gloves StandardsDocument16 pagesANSELL - Gloves StandardsAlexandru A.No ratings yet

- LNG Msds Wood Side)Document5 pagesLNG Msds Wood Side)Phuluang Ninrut Na AyuttayaNo ratings yet

- MSDS - Diesel - DemoDocument10 pagesMSDS - Diesel - Demodavid ruawNo ratings yet

- Properrties of White Mineral Oil-LightDocument8 pagesProperrties of White Mineral Oil-LightMamunNo ratings yet

- MSDS - Text Spin H (E)Document4 pagesMSDS - Text Spin H (E)Athiphap SrisupareerathNo ratings yet

- Section 3 - Chemical Waste ManagementDocument20 pagesSection 3 - Chemical Waste ManagementJayson FranciscoNo ratings yet

- Application For Fire Certificate Fire ClearanceDocument10 pagesApplication For Fire Certificate Fire ClearanceYashveer TakooryNo ratings yet

- Omm Gd705a-5 - Pen00687-00 PDFDocument343 pagesOmm Gd705a-5 - Pen00687-00 PDFAgus Wijaya100% (1)

- EIGA 15.21 Gaseous Hydrogen InstallationsDocument37 pagesEIGA 15.21 Gaseous Hydrogen InstallationsSTFNo ratings yet

- PCE Product Data Sheet: Description and Physical PropertiesDocument1 pagePCE Product Data Sheet: Description and Physical PropertiesArmando DCNo ratings yet

- M SF 142 PDFDocument43 pagesM SF 142 PDFRezaNo ratings yet

- HSE Fire Watcher TrainingDocument32 pagesHSE Fire Watcher TrainingMuneeb RehmanNo ratings yet

- Wacker Neuson G100 Operator ManualDocument78 pagesWacker Neuson G100 Operator ManualCesar Palacios ToctoNo ratings yet

- Midterm Seamanship 3Document5 pagesMidterm Seamanship 3Paulo GeneraloNo ratings yet

Welding Safety 2003

Welding Safety 2003

Uploaded by

mr. INCOGNITO0 ratings0% found this document useful (0 votes)

2 views21 pagesCopyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

2 views21 pagesWelding Safety 2003

Welding Safety 2003

Uploaded by

mr. INCOGNITOCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 21

Welding

Welding joins two pieces of metal by the use of

heat, pressure, or both

Health Hazards

Welding “Smoke” is a mixture of very fine particles called fumes

and gases

Include Chromium, nickel, arsenic, asbestos, manganese, silica,

beryllium, cadmium, nitrogen oxides, phosgene, acrolein, flourine

compounds, carbon monoxide, cobalt, copper, lead, ozone,

selenium, and zinc

come from…Base material & filler material

Coatings & paints

Shielding gases & chemical reactions

Process & consumables used

Contaminants in the air

Health Hazards

smoke” can affect any part of the body, including the

lungs, heart, kidneys, & central nervous system

Short-term effects…

Effects happen at or very soon after exposure

Long-term effects

Effects may happen after repeated

overexposures or an extended time after the

exposure

Short-term exposures

Exposure to zinc, magnesium, copper and copper

oxide can cause metal fume fever

Symptoms of metal fume fevere may occur 4 to 12

hours after exposure

Symptoms include…Chills, thirst, fever, muscle

ache, chest soreness, coughing, wheezing, fatigue,

nausea, and metallic taste in mouth

Ultraviolet rays given off by welding can react with

hydrocarbon solvents form phosgene gas may be deadly

Short-term exposures

irritate the eyes, nose, chest and respiratory tract

coughing, wheezing, shortness of breath,

bronchitis, pulmonary edema, and pneumontis

nausea, loss of appetite, vomiting, cramps, and

slow digestion

Exposure to cadmium can be fatal in a short time

Long-term exposures

welders, flame cutters, and burners have shown that

welders have an increased risk of lung cancer…

welding “smoke” can include cancer causing agents such

as…cadmium, nickel, beryllium, chromium, and arsenic

Welders may experience a variety of chronic respiratory

problems, Bronchitis, asthma, pneumonia, emphysema,

pneumoconiosis, decreased lung capacity, silicosis, and

siderosis

Long-term exposures

Heart disease, skin diseases, hearing loss, chronic

gastritis, gastroduodentis, and ulcers of the stomach and

small intestine

Reproductive risks

Heat exposure…

Heat stress, heat stroke

burns, eye injuries from hot slag, metal chips, sparks, and

hot electrodes

Other Health Risks…

Intense light can cause damage to retina

Infrared radiation may damage the cornea and result in

cataracts

May include sandy or gritty eye, blurred vision, intense pain,

tearing, burning and headache

Permanent eye damage

Skin burns and Skin cancer

Noise

Can result in stress, increased blood pressure, may contribute

to heart disease, tiredness, nervousness, and irratability

Musculoskeletal Injuries

Back injuries, shoulder pain, tendonitis, reduced

muscle strength, carpal tunnel syndrome, white

finger, and knee joint diseases

Injuries may be caused by overhead work,

vibration and heavy lifting

Electrical Hazards

danger of electric shock

Wet work areas, Cramped work spaces

Falls, fractures and other accidents can result from

electrical exposure

Even small shock can cause brain damage

Death can occur from large shocks

Electrical Precautions

Always use dry gloves

Always wear rubber soled shoes

Always use insulating layers

When working on electrically powered machinery,

make sure the frame is grounded

Keep insulation on all welding equipment and

components dry and in good condition

Don’t change electrodes with bare hands, wet gloves or

while standing on wet or ungrounded surfaces

Fire and Explosion Hazards

Intense heat and sparks can cause fires or explosions

if in the vicinity of combustible or flammable materials

performed in areas free of combustible materials such

as trash, wood, paper, textiles, plastics, chemicals,

and flammable dusts, liquids and gases

fire inspection

Dangerous Machinery

All machines in the area with moving parts must be

guarded to prevent worker’s contact

Hair, clothing, fingers, etc.

When repairing machinery by brazing and welding,

power must be disconnected, locked out, and tagged so

the machinery cannot be started up accidently

Trips and Falls

keep work areas clear of equipment, machines, cables,

and hoses

Always properly maintain and use handrails

Always use and maintain safety lines, harnesses and

lanyards

Always make sure that scaffolds are properly assembled

and used

A work area with limited access, little or no airflow, not

intended for continuous occupation

Compressed Gas Hazards

All cylinders should havecaps or regulators

Pressure regulators must be designed for gas in use

Check all equipment and components prior to use

Cylinders must be stored upright and secured

Oxygen and fuel gas cylinders must be stored

separately

Be aware of flashbacks and backfires??

Close cylinder valves when work is completed or left

unattended during breaks, etc.

Engineering Controls and Work

Practices

Substitute less hazardous materials for hazardous

materials

Use cadmium-free silver solders

Use asbestos- free electrodes, gloves, and hot pads

Use ventilation to move away or dilute hazards

Use work area barriers to protect others

Welding booths should be painted with dull finishes so

they don’t reflect UV light

Acoustic shields between the worker and noise sources

can reduce exposures

Engineering Controls and Work

Practices

Modify the process or follow safe work practices so that

hazards are eliminated or reduced to the minimum…

Don’t weld on painted surfaces; use water table under

plasma arc cutting to reduce noise; Grind instead of air-

arcing; use sub arc; position yourself away from fumes;

remove nearby flammables/combustibles; properly

maintain equipment; proper housekeeping; use lowest

possible amperage; hold electrode perpendicular and

close to work surface

Protective Clothing

Eye protection

Fire resistant gauntlet gloves

Headcap

High top hard toed shoes

Leather apron

Faceshield

Flame retardant clothing

Safety Glasses

Safety helmet

Ear plugs and/or muffs

General Precautions

properly trained and qualified

Inspect work area for fire hazards before welding

Compressed gas cylinders should always be secured in

an upright position when not in use and handled with

extreme care

Gas cylinders should be stored at least 20 feet away from

flammable materials and heat sources

Must be specific to the hazard

Must be fitted, cleaned, stored and maintained in

accordance to regulation and manufacturers specs

Other Precautions

Don’t weld on painted surfaces

Use water table to reduce noise

Properly maintain equipment

Proper housekeeping

Use lowest possible amperage

Hold electrode perpendicular and close to work

surface

Never weld or cut within 200 feet of degreasing

equipment or solvents

You might also like

- Module 3 - Basic Safety Rules & Measures of Workplace Hazards (NAC)Document91 pagesModule 3 - Basic Safety Rules & Measures of Workplace Hazards (NAC)art031125100% (8)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Ag E860 MSDS enDocument6 pagesAg E860 MSDS enFernando CalderonNo ratings yet

- Uniflux™ System: Operating InstructionsDocument164 pagesUniflux™ System: Operating InstructionsOlger Renan PulamarinNo ratings yet

- 1466F Users Guide PowerBrush Premier PDFDocument16 pages1466F Users Guide PowerBrush Premier PDFDamien Rhys JonesNo ratings yet

- SAF-T-DATA™ GuideDocument23 pagesSAF-T-DATA™ GuideBoris ChicomaNo ratings yet

- Cyclohexanone MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesCyclohexanone MSDS: Section 1: Chemical Product and Company IdentificationNada NovindaNo ratings yet

- Welding Safety: by Usha Fire Safety Equipments (P) LTDDocument43 pagesWelding Safety: by Usha Fire Safety Equipments (P) LTDAkhilesh KagNo ratings yet

- Welding Safety: Cummins Southern Plains, LTDDocument32 pagesWelding Safety: Cummins Southern Plains, LTDSaras AgrawalNo ratings yet

- Welding Safety Hazards ExplainedDocument26 pagesWelding Safety Hazards Explainedsunilmathew4477No ratings yet

- Center of Excellence For Engineering National Welding Training CenterDocument48 pagesCenter of Excellence For Engineering National Welding Training CenterAmanuel HawiNo ratings yet

- Welding Safety HazardDocument32 pagesWelding Safety HazardjeonronbacurinNo ratings yet

- Welding Hazards AFSCME Fact SheetDocument11 pagesWelding Hazards AFSCME Fact SheetMuhammad Attaulla KhanNo ratings yet

- Welding SafetyDocument17 pagesWelding SafetySETIAJI WIBAWANo ratings yet

- Safety Measures in Pharmaceutical IndustriesDocument31 pagesSafety Measures in Pharmaceutical Industriesabdullah18oowNo ratings yet

- Work Instruction For Welder: Pre-Operation Check For SafetyDocument4 pagesWork Instruction For Welder: Pre-Operation Check For SafetyNnandkishoreNo ratings yet

- Weld Safe For StudentsDocument4 pagesWeld Safe For StudentsCharlyn PandaNo ratings yet

- Safety Precaution in Welding: Ashok Kumar Engineer Sales-Chennai D&H Secheron Electrodes PVT - LTDDocument36 pagesSafety Precaution in Welding: Ashok Kumar Engineer Sales-Chennai D&H Secheron Electrodes PVT - LTDPrakash RajNo ratings yet

- Welding Safety: Amit Gola Assistant Director (Safety)Document21 pagesWelding Safety: Amit Gola Assistant Director (Safety)Vishwash GoyalNo ratings yet

- JSA Detailed InfoDocument15 pagesJSA Detailed InfoGuptaNo ratings yet

- Surindra Engineering Co. LTD - Environmental Health & Safety DepartmentDocument70 pagesSurindra Engineering Co. LTD - Environmental Health & Safety DepartmentRushabh KapadiaNo ratings yet

- Safety Precautions in Welding - 0Document14 pagesSafety Precautions in Welding - 0Jaén García EnriquetaNo ratings yet

- 1 Welding SafetyDocument51 pages1 Welding SafetyAfshadNo ratings yet

- TYPES OF PPE YOU CAN USE TranslatorDocument3 pagesTYPES OF PPE YOU CAN USE TranslatorDiego Aarón AvendañoNo ratings yet

- Day 5 Apply-Safety-PracticesDocument16 pagesDay 5 Apply-Safety-Practicestrustfaith49No ratings yet

- Industrial Hazards: Thomas Shelby ID: 2063269060 Roll: 29Document9 pagesIndustrial Hazards: Thomas Shelby ID: 2063269060 Roll: 29Morshed AbirNo ratings yet

- Welding Safety Kemp Rev909Document64 pagesWelding Safety Kemp Rev909Mohammad AshpakNo ratings yet

- Plate MsdsDocument7 pagesPlate MsdsShawn ChiassonNo ratings yet

- WeldingDocument2 pagesWeldingGhodke ParmeshwarNo ratings yet

- Apply Safety PracticesDocument59 pagesApply Safety PracticesEugenio Jr. MatesNo ratings yet

- Arc Welding Safety PrecautionsDocument64 pagesArc Welding Safety Precautionsbarry bonzoNo ratings yet

- Written Report: Electrical Safety Hazards Negative Effects of Inhaling Fumes From Soldering Iron ComponentsDocument8 pagesWritten Report: Electrical Safety Hazards Negative Effects of Inhaling Fumes From Soldering Iron ComponentsAliceNo ratings yet

- Common 1 General Safety Precaution in WeldingDocument49 pagesCommon 1 General Safety Precaution in WeldingEgghead YTCNo ratings yet

- Safety in WeldingDocument3 pagesSafety in WeldingNAGABHUSHAN CPNo ratings yet

- Personal Protective Equipment: Office of Environmental, Health, & SafetyDocument70 pagesPersonal Protective Equipment: Office of Environmental, Health, & SafetyPedro SousaNo ratings yet

- Welding RulesDocument2 pagesWelding Rulesapi-626529020No ratings yet

- Smaw 12 Module 1Document7 pagesSmaw 12 Module 1Francis Rico Mutia RufonNo ratings yet

- Installation and Maintenance of ServicesDocument68 pagesInstallation and Maintenance of Servicesgodson.jacksonNo ratings yet

- Xti-160 Xti-161 DV: Operator ManualDocument16 pagesXti-160 Xti-161 DV: Operator ManualVicente SarmientoNo ratings yet

- Ppe American STDSDocument30 pagesPpe American STDSChetana HamsagarNo ratings yet

- 9-Welding and CuttingDocument19 pages9-Welding and CuttingAhmed AbbasNo ratings yet

- MIG-200L ManualDocument30 pagesMIG-200L ManualV-Man systemNo ratings yet

- Practical Work Book For Health Safety and EnvironmentDocument69 pagesPractical Work Book For Health Safety and EnvironmentAreejNo ratings yet

- Robin Rajan 18 Types of Ppe, Reapiratory and Non RespiratoryDocument22 pagesRobin Rajan 18 Types of Ppe, Reapiratory and Non Respiratoryrobin rajanNo ratings yet

- Final Health and SafetyDocument11 pagesFinal Health and SafetyMalka Melani JayaweeraNo ratings yet

- Freelander 2 BADocument6 pagesFreelander 2 BAJim LiebNo ratings yet

- 1 Electric Gas Welding SafetyDocument34 pages1 Electric Gas Welding SafetyPrincess Mae DesaculaNo ratings yet

- Safety Precautions in Welding Operation1Document11 pagesSafety Precautions in Welding Operation1sivaNo ratings yet

- ARC630Document90 pagesARC630VVan TanNo ratings yet

- Construction Safety - Part 3 (Ppe)Document27 pagesConstruction Safety - Part 3 (Ppe)Henry TuraldeNo ratings yet

- PosterDocument3 pagesPosterRahul NambiarNo ratings yet

- Lesson 08 Basic Occupational Safety and HealthDocument75 pagesLesson 08 Basic Occupational Safety and HealthJohn MaloneNo ratings yet

- Atig 400Document48 pagesAtig 400VVan TanNo ratings yet

- Mig 250c ManualDocument18 pagesMig 250c ManualBondan PratamaNo ratings yet

- Electrical InstallationDocument4 pagesElectrical Installationonchiriemmanuel891No ratings yet

- Shielded Metal Arc Welding NciiDocument8 pagesShielded Metal Arc Welding NciiElla MaeNo ratings yet

- Plasma YH-400 English ManualDocument29 pagesPlasma YH-400 English ManualOLVERACNCMAQUINAS EMPRESANo ratings yet

- SIF MTS300/400 Welder ManualDocument20 pagesSIF MTS300/400 Welder Manualsteven5140No ratings yet

- Kompakt 160Document180 pagesKompakt 160mihai37No ratings yet

- Tic MachineDocument33 pagesTic MachineDaniel AlmendarezNo ratings yet

- GMAW Facilitator GuideDocument42 pagesGMAW Facilitator GuideEng trk100% (1)

- Manual ATIG PACDocument82 pagesManual ATIG PACindo jasunNo ratings yet

- Laboratory Safety HEMA Chapter 2Document34 pagesLaboratory Safety HEMA Chapter 2Pam FajardoNo ratings yet

- 9 PpeDocument22 pages9 PpepokiningNo ratings yet

- Welding for Off-Road Beginners: This Book Includes - Welding for Beginners in Fabrication & Off-Road WeldingFrom EverandWelding for Off-Road Beginners: This Book Includes - Welding for Beginners in Fabrication & Off-Road WeldingRating: 5 out of 5 stars5/5 (2)

- (D-03573) DISTILLED WATER (D.M.Water)Document8 pages(D-03573) DISTILLED WATER (D.M.Water)sureshNo ratings yet

- Dyson DC32Document7 pagesDyson DC32philaskNo ratings yet

- TP6053 Catalago KohlerDocument70 pagesTP6053 Catalago KohlerOperaciones Max Diesel ProNo ratings yet

- Inverter 201 Ultra PFC ManualDocument44 pagesInverter 201 Ultra PFC ManualParadox UtopiaNo ratings yet

- R30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFDocument219 pagesR30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFdenix49No ratings yet

- 7 Hazardous LocationsDocument7 pages7 Hazardous LocationsBechir OuhibiNo ratings yet

- OBM Viscosifier - LiquidDocument3 pagesOBM Viscosifier - LiquidPranav DubeyNo ratings yet

- According To Iso 7010: Safety SignsDocument1 pageAccording To Iso 7010: Safety SignsKirankumar PanchalNo ratings yet

- Complete 1000+ Error DetectingDocument159 pagesComplete 1000+ Error DetectingVikashNo ratings yet

- Es 120 - 252Document16 pagesEs 120 - 252ulvi ganjaliNo ratings yet

- ANSELL - Gloves StandardsDocument16 pagesANSELL - Gloves StandardsAlexandru A.No ratings yet

- LNG Msds Wood Side)Document5 pagesLNG Msds Wood Side)Phuluang Ninrut Na AyuttayaNo ratings yet

- MSDS - Diesel - DemoDocument10 pagesMSDS - Diesel - Demodavid ruawNo ratings yet

- Properrties of White Mineral Oil-LightDocument8 pagesProperrties of White Mineral Oil-LightMamunNo ratings yet

- MSDS - Text Spin H (E)Document4 pagesMSDS - Text Spin H (E)Athiphap SrisupareerathNo ratings yet

- Section 3 - Chemical Waste ManagementDocument20 pagesSection 3 - Chemical Waste ManagementJayson FranciscoNo ratings yet

- Application For Fire Certificate Fire ClearanceDocument10 pagesApplication For Fire Certificate Fire ClearanceYashveer TakooryNo ratings yet

- Omm Gd705a-5 - Pen00687-00 PDFDocument343 pagesOmm Gd705a-5 - Pen00687-00 PDFAgus Wijaya100% (1)

- EIGA 15.21 Gaseous Hydrogen InstallationsDocument37 pagesEIGA 15.21 Gaseous Hydrogen InstallationsSTFNo ratings yet

- PCE Product Data Sheet: Description and Physical PropertiesDocument1 pagePCE Product Data Sheet: Description and Physical PropertiesArmando DCNo ratings yet

- M SF 142 PDFDocument43 pagesM SF 142 PDFRezaNo ratings yet

- HSE Fire Watcher TrainingDocument32 pagesHSE Fire Watcher TrainingMuneeb RehmanNo ratings yet

- Wacker Neuson G100 Operator ManualDocument78 pagesWacker Neuson G100 Operator ManualCesar Palacios ToctoNo ratings yet

- Midterm Seamanship 3Document5 pagesMidterm Seamanship 3Paulo GeneraloNo ratings yet