Professional Documents

Culture Documents

STD ACT: CLL Not Glow CLL Not Glow

STD ACT: CLL Not Glow CLL Not Glow

Uploaded by

tn07ck62040 ratings0% found this document useful (0 votes)

1 views1 pageOriginal Title

E37-15.04.24

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views1 pageSTD ACT: CLL Not Glow CLL Not Glow

STD ACT: CLL Not Glow CLL Not Glow

Uploaded by

tn07ck6204Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 1

IJL

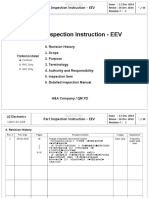

Part name : E37 HL 3.WHY WHY Analysis :

Date : 26/03/24 Why-1 CLL Not Glow

Why-2 Capacitor fallen inside the lamp

Problem : CLL Not Glow at Customer End

STD ACT Why-3 Capacitor broken on PCB

DRL Glow DRL Glow Why-4 Capacitor soldering weak

Why-5 Rework(old) lamp reviewed (2022-2024)

Low+CLL Low Beam Glow

Glow CLL Not Glow 4.Rework Procedure :

STD ACT Result

Low +High+ Low +High Glow Rework Procedure to be followed Rework Procedure followed- Date

CLL Glow CLL Not Glow Stamp / light testing Done

SOP to be followed SOP Followed ( Light + Leak Test)

1.Occurrence study :

Team leader to be Used for Lamp Rework L3 Skilled Manpower used for Rework

Bracket+ Ref B + PCB

Body + Ref Assy Ref B + Inner

PCB Assy Assy

lens QC Person to be Involved while rework Production person Involved

Assy

5.Action Plan :

Problem Root Cause Permanent Action

Lens Leak +

Glue

Pressing Light Testing Final

Dispensing SOP Revised - 24hrs Rule created (OK/NG)

Inspection CLL Not Rework

Root cause Analysis to be done by Dis- assy check

2.4M Analysis : Glow at part for functional defects.

Customer re- 10 cycle SOP audit by each shift TL/SL/Manager

Man : No change Review System procedure changed

Machine : No change viewed (Before - prod After - Prod + QC )

Material : No change

Method : Change

Lighting for your Safety 1

CONFIDENTIAL

You might also like

- MINI6600: Service ManualDocument232 pagesMINI6600: Service ManualChuck Patti100% (5)

- CP Bourg BSTD CDDocument118 pagesCP Bourg BSTD CDtraminer80% (5)

- The 7QB of Production: FAS Training PresentationDocument50 pagesThe 7QB of Production: FAS Training Presentationcong da100% (1)

- CQI-12 Coating System 3-29-16Document71 pagesCQI-12 Coating System 3-29-16Georgeta ComanNo ratings yet

- Andrew MW 2.4mDocument5 pagesAndrew MW 2.4m'Theodora GeorgianaNo ratings yet

- GBE-KPO-2-025-00 Poka YokeDocument85 pagesGBE-KPO-2-025-00 Poka YokeEduardo Magana100% (1)

- (IQC) LG (67) - G3-1214 - Grille Assembly Discharge - Detailed Inspection ProcedureDocument15 pages(IQC) LG (67) - G3-1214 - Grille Assembly Discharge - Detailed Inspection ProcedureAnonymous Lta32Ta9No ratings yet

- CYP DVT Report 20221012Document17 pagesCYP DVT Report 20221012QuýNguyễnNo ratings yet

- GBE-KPO-2-032-00 5 WhyDocument25 pagesGBE-KPO-2-032-00 5 WhyEduardo MaganaNo ratings yet

- QRQCDocument1 pageQRQCmoez50% (2)

- Lab4 Baliguat Dennis IvanDocument3 pagesLab4 Baliguat Dennis IvanDennis IvanNo ratings yet

- GBE-KPO-2-006-00 Standard WorkDocument65 pagesGBE-KPO-2-006-00 Standard WorkEduardo MaganaNo ratings yet

- RESP./ Date Verification (Qa Pic) Improvement Action Root Cause / Analysis Issue Detail StatusDocument2 pagesRESP./ Date Verification (Qa Pic) Improvement Action Root Cause / Analysis Issue Detail StatusSameer SaxenaNo ratings yet

- Adidas - Quality Concept Best PracticeDocument24 pagesAdidas - Quality Concept Best Practicemgttrainee16No ratings yet

- Session 1 Photometric Measrement Based On CIE S 025Document82 pagesSession 1 Photometric Measrement Based On CIE S 025Marce MangaoangNo ratings yet

- 8D CT Interchnaged - NNLDocument10 pages8D CT Interchnaged - NNLAbhinav SinghNo ratings yet

- PR.R - Issue Wrong Assemble Seal MotorDocument12 pagesPR.R - Issue Wrong Assemble Seal MotorVan Ba VuNo ratings yet

- 4M Change Management PresentationDocument42 pages4M Change Management PresentationSARAI MARINNo ratings yet

- SECTION 417-02 Interior LightingDocument20 pagesSECTION 417-02 Interior LightingTiến Phát Công ty TNHH Đầu Tư Xây DựngNo ratings yet

- LG (67) - G3-1028-EEV Eng Rev 1Document10 pagesLG (67) - G3-1028-EEV Eng Rev 1Anonymous Lta32Ta9No ratings yet

- Analyze Problem Coupler O2 Sensor BKUDocument10 pagesAnalyze Problem Coupler O2 Sensor BKUmutiara.dewiNo ratings yet

- Pre-Shipment Inspection: Product PhotoDocument35 pagesPre-Shipment Inspection: Product Photo123456No ratings yet

- Lighting Selection ChecklistDocument1 pageLighting Selection ChecklistmuzammalNo ratings yet

- 8D Report For VDC Wrong - NNLDocument10 pages8D Report For VDC Wrong - NNLAbhinav SinghNo ratings yet

- PFMEA Import FormatDocument1 pagePFMEA Import FormatMani Rathinam RajamaniNo ratings yet

- Siemens Internship ReportDocument17 pagesSiemens Internship ReportmirfanbilalNo ratings yet

- Advanced Process Control-Advanced ServicesDocument89 pagesAdvanced Process Control-Advanced ServicesxincherduNo ratings yet

- Ag PEB 66 67Document4 pagesAg PEB 66 67Anggraini NRealNo ratings yet

- SPE WI W.Shop WIF GuidelineDocument20 pagesSPE WI W.Shop WIF Guidelineibrahimletaief1985No ratings yet

- LG (67) - G3-1009-Fan (Turbo) G v.2Document9 pagesLG (67) - G3-1009-Fan (Turbo) G v.2Anonymous Lta32Ta9No ratings yet

- Assembly Lean Assessmentv1Document19 pagesAssembly Lean Assessmentv1Leontin LeonNo ratings yet

- LG (67) - G3-1007 Fan (Propeller) G v.2Document10 pagesLG (67) - G3-1007 Fan (Propeller) G v.2Anonymous Lta32Ta9No ratings yet

- M & E QC Plan - 01b REV. 0Document4 pagesM & E QC Plan - 01b REV. 0Anonymous 3eHGEDbxNo ratings yet

- 8D FormatDocument12 pages8D FormatMd sameerNo ratings yet

- Best Practices-RelianceDocument47 pagesBest Practices-Reliancepramod_nandaNo ratings yet

- Problem: Part Hight Out of Spec Problem PhotoDocument8 pagesProblem: Part Hight Out of Spec Problem PhotoManikandanNo ratings yet

- PPPL-NPD-QSP-02 - Initial Part ControlDocument3 pagesPPPL-NPD-QSP-02 - Initial Part Controlcghodake1No ratings yet

- ConcernsDocument4 pagesConcernsSrikanthNo ratings yet

- Caliper For New Technologies?: Ruth TaylorDocument30 pagesCaliper For New Technologies?: Ruth TaylorinzanerNo ratings yet

- SPS Section 3 V3.0 EnglishDocument56 pagesSPS Section 3 V3.0 EnglishjustinNo ratings yet

- Alternative DaylightDocument1 pageAlternative DaylightjupiracaNo ratings yet

- Laboratory Assessment Faculty of Electrical Engineering Universiti Teknologi Mara Electrical Engineering Laboratory 3 (Eee525)Document4 pagesLaboratory Assessment Faculty of Electrical Engineering Universiti Teknologi Mara Electrical Engineering Laboratory 3 (Eee525)Muhamad Nur Firdaus Bin MunirNo ratings yet

- OK-Rvd-D-Q10-Procedure For Outsourced Activities & Its Control Parameters Rev 04-18.6.24Document3 pagesOK-Rvd-D-Q10-Procedure For Outsourced Activities & Its Control Parameters Rev 04-18.6.24navneetNo ratings yet

- GBE-KPO-2-008-00 Cell DesignDocument50 pagesGBE-KPO-2-008-00 Cell DesignEduardo MaganaNo ratings yet

- Incident ReportDocument29 pagesIncident Reportharjan2507No ratings yet

- Quick Changeover SmedDocument33 pagesQuick Changeover SmedAnonymous O1xkZINNo ratings yet

- CK Nac Mindray bs-400Document1 pageCK Nac Mindray bs-400rizal_aspanNo ratings yet

- Modern Nissan Catalytic Converter DiagnosisDocument7 pagesModern Nissan Catalytic Converter DiagnosisSecarianu Florentin RazvanNo ratings yet

- EPRI PMBD Gap Analysis TemplateDocument4 pagesEPRI PMBD Gap Analysis TemplatedanishaslNo ratings yet

- 2b AIAG CQI 12 Coating System AssessmentDocument69 pages2b AIAG CQI 12 Coating System AssessmentAngie GuerreroNo ratings yet

- Connecting Pre-Si and Post-Si VerificationDocument25 pagesConnecting Pre-Si and Post-Si VerificationkvishakhaNo ratings yet

- GBE-KPO-2-010-00 Work Load LevellingDocument81 pagesGBE-KPO-2-010-00 Work Load LevellingEduardo Magana100% (1)

- Pgurl Evalboard - Doidncp1251gevb - Doidncp1251gevbDocument1 pagePgurl Evalboard - Doidncp1251gevb - Doidncp1251gevbRey FloresNo ratings yet

- Incident: What Was The Problem? (5W+2H)Document3 pagesIncident: What Was The Problem? (5W+2H)Gyanveer SinghNo ratings yet

- Rapid Problem Solving (RPS) /8D: IS: Is NotDocument2 pagesRapid Problem Solving (RPS) /8D: IS: Is NotprashanthNo ratings yet

- Mahindra Bolt Loosening Issue 3.10.2017Document24 pagesMahindra Bolt Loosening Issue 3.10.2017Sridharan VenkatNo ratings yet

- GSM SilentCall and NBR AuditDocument9 pagesGSM SilentCall and NBR AuditPanus AssawirojruengNo ratings yet

- LMM - JJS - PPT 5A - Lean Tools & TechniquesDocument165 pagesLMM - JJS - PPT 5A - Lean Tools & TechniquesAby Reji ChemmathuNo ratings yet

- SPC SimplifiedDocument2 pagesSPC SimplifiedVenodaren VelusamyNo ratings yet

- LED Light Repair TechnicianDocument23 pagesLED Light Repair TechniciangulfamNo ratings yet

- FRM QUA 506 Process Audit Sheet 1Document2 pagesFRM QUA 506 Process Audit Sheet 1Ravi javaliNo ratings yet

- Cqi 12 Coating System 3 8 12 FinalDocument71 pagesCqi 12 Coating System 3 8 12 Finalgocohov660No ratings yet

- Experiment 2Document14 pagesExperiment 2Mayur RamavatNo ratings yet

- Presentation On SPS: (Special Protection Scheme)Document9 pagesPresentation On SPS: (Special Protection Scheme)Abhishek SinhaNo ratings yet

- ResearchDocument4 pagesResearchNikko PatunganNo ratings yet

- Datasheet Az431Document20 pagesDatasheet Az43193082No ratings yet

- EC6401 Electronic Circuits II Syllabus With Anna University Previous Questions Regulation 2013Document1 pageEC6401 Electronic Circuits II Syllabus With Anna University Previous Questions Regulation 2013Dharani KumarNo ratings yet

- Mobile Tower and Mobile Phone Radiation Hazards - Prof Girish KumarDocument52 pagesMobile Tower and Mobile Phone Radiation Hazards - Prof Girish KumarNeha KumarNo ratings yet

- Rajiv Gandhi University of Knowledge Technologies, BasarDocument2 pagesRajiv Gandhi University of Knowledge Technologies, BasarGUMPULA ROHITH JOSHUA B182487No ratings yet

- Terra 360-180-60 Series 1 - CE - Installation and Operation Manual - en - V003Document123 pagesTerra 360-180-60 Series 1 - CE - Installation and Operation Manual - en - V003contatoNo ratings yet

- Best Collection of Mouse Types - Hafeez Center Online StoreDocument3 pagesBest Collection of Mouse Types - Hafeez Center Online StoreRichardNo ratings yet

- DC TESLA COIL Construction and ApllicatiDocument5 pagesDC TESLA COIL Construction and ApllicatiwoodNo ratings yet

- Skan Mobile XRAYDocument2 pagesSkan Mobile XRAYJC ZorrovskiNo ratings yet

- Homework 8 TCDocument12 pagesHomework 8 TCSebastián TorresNo ratings yet

- Calculator Repair Instructions: TI 83 and TI-83 PLUSDocument2 pagesCalculator Repair Instructions: TI 83 and TI-83 PLUSjozoceNo ratings yet

- Procedure and Macros NotesDocument7 pagesProcedure and Macros NotesBoy BearishNo ratings yet

- Capitole 40Document20 pagesCapitole 40ImtiazAhmedNo ratings yet

- 8-Bit Single Chip Microcontroller LC87F67C8ADocument27 pages8-Bit Single Chip Microcontroller LC87F67C8AAlbert GTNo ratings yet

- 7SR242 - Duobias Technical Manual Chapter 02 Settings, Configuration and InstrumentsDocument20 pages7SR242 - Duobias Technical Manual Chapter 02 Settings, Configuration and InstrumentsssNo ratings yet

- Project Final Report On Home AutomationDocument120 pagesProject Final Report On Home AutomationManish Yadav78% (77)

- Introduction To Analog and Digital Communications: Simon Haykin, Michael MoherDocument64 pagesIntroduction To Analog and Digital Communications: Simon Haykin, Michael MoherAmr AbdelnaserNo ratings yet

- Preface Broadcasting Handbook: TuggleDocument18 pagesPreface Broadcasting Handbook: TuggleAndy Nmn PhamNo ratings yet

- Parameter Setting NSMDocument1 pageParameter Setting NSMKrishna JashaNo ratings yet

- Arduino Tutorials - The AREF PinDocument4 pagesArduino Tutorials - The AREF Pinmask6622000No ratings yet

- KV650C2Document4 pagesKV650C2Anonymous DuwQk4iNo ratings yet

- P345 Relay Test ReportDocument18 pagesP345 Relay Test ReportSuresh Kuttan100% (3)

- 8051 Development Board Circuit DiagramDocument1 page8051 Development Board Circuit DiagramRohan DharmadhikariNo ratings yet

- Harmonic Filtering of High-Power 12-Pulse Rectifier Loads With A Selective Hybrid Filter SystemDocument10 pagesHarmonic Filtering of High-Power 12-Pulse Rectifier Loads With A Selective Hybrid Filter Systemnareshkumar KNo ratings yet