Professional Documents

Culture Documents

5S - Levels of Excellence

5S - Levels of Excellence

Uploaded by

Ramanagiri BharathanCopyright:

Available Formats

You might also like

- Spare Parts Inventory Management: A Complete Guide to SparesologyFrom EverandSpare Parts Inventory Management: A Complete Guide to SparesologyRating: 4 out of 5 stars4/5 (3)

- 5 S ChecklistsDocument11 pages5 S Checklistsjahazi2No ratings yet

- 5S - Excellence Assessment PDFDocument2 pages5S - Excellence Assessment PDFAshokNo ratings yet

- 5 S Presentation Basic TrainingDocument82 pages5 S Presentation Basic TrainingEmman Bosito100% (2)

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- 5S Training and ImplementationDocument66 pages5S Training and ImplementationLlehk FranciscoNo ratings yet

- 5S - Levels of ExcellenceDocument2 pages5S - Levels of ExcellenceHartoyo SwiNo ratings yet

- 5S Checklist - Area: 5S Check Item Guidance RatingDocument5 pages5S Checklist - Area: 5S Check Item Guidance Ratingakbars.thasimaNo ratings yet

- TQM Chapter 5Document8 pagesTQM Chapter 5KENNETH IAN MADERANo ratings yet

- 5S - Check ListDocument3 pages5S - Check ListJayendra RajeshirkeNo ratings yet

- 5S Audit FormDocument2 pages5S Audit FormNavnath Tamhane100% (2)

- 5S Audit FormDocument2 pages5S Audit Formmounirs719883No ratings yet

- 5S Audit FormDocument2 pages5S Audit FormWaqar DarNo ratings yet

- 5SDocument56 pages5SInderpreet Singh AhujaNo ratings yet

- 5S and Workplace Productivity CLADocument48 pages5S and Workplace Productivity CLASteben MeuerteNo ratings yet

- 5S TrainingDocument32 pages5S TrainingQuest Certification B.KarthikeyanNo ratings yet

- Category Criteria Audit Period Scoring System: PLS Office 5S + Safety Audit Form - DraftDocument109 pagesCategory Criteria Audit Period Scoring System: PLS Office 5S + Safety Audit Form - DraftblitzkrigNo ratings yet

- 5S ManualDocument23 pages5S ManualBittuNo ratings yet

- What Is 5S?Document37 pagesWhat Is 5S?wferry27No ratings yet

- Chapter 5 Good HousekeepingDocument29 pagesChapter 5 Good HousekeepingOmar KatogNo ratings yet

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Document44 pagesSort Set-In-Order Shine Standardize Sustain: What Is 5-S?Angel David ChavezNo ratings yet

- S5 - Sustain: 5S Housekeeping Score SheetDocument1 pageS5 - Sustain: 5S Housekeeping Score SheetRama PrasetiaNo ratings yet

- About 5 SDocument9 pagesAbout 5 SKharolina BautistaNo ratings yet

- 5S ChecklistsDocument5 pages5S ChecklistsRheneir MoraNo ratings yet

- Reported By: Ms. Laarni P. LacandazoDocument36 pagesReported By: Ms. Laarni P. Lacandazolpl_0124No ratings yet

- Presentation 6 S STARTER TrainingDocument96 pagesPresentation 6 S STARTER Trainingm_ramas2001No ratings yet

- Module 5 - TQMDocument8 pagesModule 5 - TQMRevenlie GalapinNo ratings yet

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- 5s Step by Step GuideDocument10 pages5s Step by Step GuideKalkidan MekuriyaNo ratings yet

- LESSON 2-Occupational Health and SafetyDocument6 pagesLESSON 2-Occupational Health and Safetymelanielampera17No ratings yet

- 5SSSSSDocument19 pages5SSSSSHoàng Thị NguyênNo ratings yet

- 5'S ManualDocument44 pages5'S ManualSayan KonarNo ratings yet

- Stangerweb 5S Audit QuestionnaireDocument4 pagesStangerweb 5S Audit QuestionnaireambicaNo ratings yet

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Document40 pagesSort Set-In-Order Shine Standardize Sustain: What Is 5-S?blitzkrigNo ratings yet

- 5-S Handbook For Operations Depot 105/NBE-AM: TNT Express Germany Road Hub and Depot NürnbergDocument24 pages5-S Handbook For Operations Depot 105/NBE-AM: TNT Express Germany Road Hub and Depot NürnbergthomasarnosanderNo ratings yet

- 5s ReportDocument15 pages5s ReportAkash KarbotkarNo ratings yet

- 5s in Simba Apparels KenyaDocument19 pages5s in Simba Apparels KenyaPrerna Khatri100% (1)

- What Are The Five SDocument4 pagesWhat Are The Five Ssaman2580No ratings yet

- Assignment TQM 4Document5 pagesAssignment TQM 4Aiswarya ASNo ratings yet

- Assignment On Achieving Quality With 5 S AQM M.F.Tech - II SemDocument26 pagesAssignment On Achieving Quality With 5 S AQM M.F.Tech - II SempetcutpaulNo ratings yet

- Five SDocument41 pagesFive Srolly curiaNo ratings yet

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Document43 pagesSort Set-In-Order Shine Standardize Sustain: What Is 5-S?Navnath TamhaneNo ratings yet

- World Class Manufacturing PracticesDocument5 pagesWorld Class Manufacturing PracticesSumit_Raj_Patn_8373No ratings yet

- 5s Audit Check SheetDocument4 pages5s Audit Check SheetLAI WEI SINGNo ratings yet

- Module For Operations Management and TQM Part 5Document7 pagesModule For Operations Management and TQM Part 5Karyll JustoNo ratings yet

- 5SDocument12 pages5SJanzen BascoNo ratings yet

- Module 4 - Housekeeping (Occupational Safety)Document20 pagesModule 4 - Housekeeping (Occupational Safety)Sam100% (1)

- 5s ShortDocument24 pages5s ShortSMAKNo ratings yet

- Office 5s ChecklistDocument109 pagesOffice 5s ChecklistSercan Sülün100% (1)

- Five S Program: Sort (Clean Up)Document3 pagesFive S Program: Sort (Clean Up)Gina GuillénNo ratings yet

- Office 5S ChecklistDocument15 pagesOffice 5S ChecklisttahirNo ratings yet

- Introduction To "5S"..Document23 pagesIntroduction To "5S"..Rahul SharmaNo ratings yet

- 5S Audit ReportDocument8 pages5S Audit Reportmananshah89No ratings yet

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- Sticky Solutions: 99 Clever Tricks with Sticky Notes: 99 TricksFrom EverandSticky Solutions: 99 Clever Tricks with Sticky Notes: 99 TricksNo ratings yet

- Becoming Lean: Practical Steps to Build CompetitivenessFrom EverandBecoming Lean: Practical Steps to Build CompetitivenessRating: 5 out of 5 stars5/5 (1)

5S - Levels of Excellence

5S - Levels of Excellence

Uploaded by

Ramanagiri BharathanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5S - Levels of Excellence

5S - Levels of Excellence

Uploaded by

Ramanagiri BharathanCopyright:

Available Formats

SORTING SIMPLIFYING SWEEPING STANDARDIZING

SUSTAINING

LEVEL

5

Focus on

Prevention

Employees are

continually seeking

improvement

opportunities.

A dependable,

documented method has

been developed to

provide continual

evaluation, and a

process is in place to

implement improvements.

Area employees

have devised a

dependable,

documented method

of preventive cleaning

and maintenance.

Everyone is continually

seeking the elimination of

waste with changes

documented and

information shared.

There is a general appearance

of a confident understanding

of, and adherence to, the 5S

principles.

LEVEL

4

Focus on

Consistency

A dependable,

documented

method has been

established to keep

the work area free

of unnecessary

items.

A dependable,

documented method has

been established to

recognize in a visual

sweep if items are out of

place or exceed quantity

limits.

5S agreements are

understood and

practiced continually.

Substantial process

documentation is available

and followed.

Follow-through with 5S

agreements and safety

practices is evident.

LEVEL

3

Make it visuaI

Unnecessary items

have been

removed from the

workplace.

Designated locations are

marked to make

Organization more

visible.

Work/break areas

and machinery are

cleaned on a daily

basis. Visual controls

have been

established and

marked.

Working environment

changes are being

documented. Visual control

agreements for labeling and

quantity levels established.

5S agreements and safety

practices have been

developed and are utilized.

LEVEL

2

Focus on

Basics

Necessary and

unnecessary items

are separated.

A designated location

has been established for

items.

Work/breaks areas

are cleaned on a

regular scheduled

basis. Key tems to

check have been

identified.

Methods are being

improved but changes

haven' been documented.

A recognizable effort has been

made to improve the condition

of the workplace.

LEVEL

1

Just

Beginning

Needed and not

needed items are

mixed throughout

the work place.

tems are randomly

located throughout the

work place.

Work place areas are

dirty, disorganized

and key items not

marked or identified.

Work place methods are

not consistently followed

and are undocumented.

Work place checks are

randomly performed and there

is no visual measurement of 5S

performance.

5S Levels oI Excellence

All cleaning equipment is stored in a neat manner; handy & easily

available when needed. (Papertowels, duster, Lysol, glass cleaner)

All floors are clean & free of debris & dirt.

No outdated, torn, or soiled announcements are displayed.

Bulletin Boards are arranged in a straight, neat manner, & properly

mounted.

Emergency evacuation plans are in place & 5ersonneI knows

where Iocated .

Detailed instructions put together with the intent to make sure if a

person is absent from their job, a person could step in & find their

way around the work area, important for critical operations.

18

5S ControI &

Maintenance

There is a disciplined system of control & maintenance to assure

that each of the above items is maintained at the highest possible

level. t is the responsibility of the team to maintain this system.

The 5S poster is displayed in a prominent place, & everyone

understands it.

17

SheIves, FiIe

Cabinets, & Desks -

Arrangement &

Maintenance

Shelves, file cabinets & desks are arranged, divided & clearly

labeled to make it obvious where things are stored. They are kept

free of unused objects. tems are returned to proper location after

each use.

16

Deskto5 Work

Instructions/

Binder AvaiIabIe

15 FiIing Filing system is visible and easy to understand.

14

Documents -

Storage/ControI

Only documents necessary to the work are stored at desks; such

documents & binders are stored in a neat & orderly manner & a

visual management system for these items are in place. No

unlabeled binders/documents are present. Obsolete or unused

documents are removed.

Nothing is stored on top of computers, cabinets, or equipment;

nothing leans against the walls or columns.

13

Equi5ment -

Storage

12 Badges Badges are worn by all employees.

All binders are labeled and clearly identified. 11 Binders

10

Equi5ment

(Com5uters,

5rinters, faxes)

All machines & equipment are kept clean (free of extra paper) by

routine daily care. Computer screens & key boards are clean,

windows & desktops are clean - no dust bunnies.

9 LabeIing Drawers & file folders are clearly labeled preferably typed.

8 Coat Racks

7

Desk/Com5uter

Storage

Nothing is stored under desk. Computer files (e-mail deleted &

recycle bin) are kept neat, cleaned out, and organized.

Coat racks are available and coats are stored there, not on the

backs of chairs.

6 Storage on FIoor

5

Emergency

Access &

Evacuation PIan

Large items such as storage boxes are not routinely stored on the

floor. Extension cords are properly organized and stored.

4 BuIIetin Boards

3 FIoor CIeaning

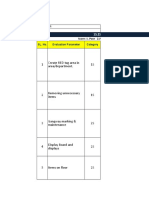

#

2

CIeaning

Equi5ment

GeneraI

A55earance

1

Office has a well organized, clean, neat professional look. tems

not required for performing work are removed from the workplace.

Personal items are stored in one drawer.

TotaI Score: Divided by 18 = Avg. Score:

Date: Area: Performed by:

Descri5tion

Scoring Criteria

Rating Scale: 0-5 (poor = 0, excellent = 5)

Item

Score Notes for next IeveI im5rovement

You might also like

- Spare Parts Inventory Management: A Complete Guide to SparesologyFrom EverandSpare Parts Inventory Management: A Complete Guide to SparesologyRating: 4 out of 5 stars4/5 (3)

- 5 S ChecklistsDocument11 pages5 S Checklistsjahazi2No ratings yet

- 5S - Excellence Assessment PDFDocument2 pages5S - Excellence Assessment PDFAshokNo ratings yet

- 5 S Presentation Basic TrainingDocument82 pages5 S Presentation Basic TrainingEmman Bosito100% (2)

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- 5S Training and ImplementationDocument66 pages5S Training and ImplementationLlehk FranciscoNo ratings yet

- 5S - Levels of ExcellenceDocument2 pages5S - Levels of ExcellenceHartoyo SwiNo ratings yet

- 5S Checklist - Area: 5S Check Item Guidance RatingDocument5 pages5S Checklist - Area: 5S Check Item Guidance Ratingakbars.thasimaNo ratings yet

- TQM Chapter 5Document8 pagesTQM Chapter 5KENNETH IAN MADERANo ratings yet

- 5S - Check ListDocument3 pages5S - Check ListJayendra RajeshirkeNo ratings yet

- 5S Audit FormDocument2 pages5S Audit FormNavnath Tamhane100% (2)

- 5S Audit FormDocument2 pages5S Audit Formmounirs719883No ratings yet

- 5S Audit FormDocument2 pages5S Audit FormWaqar DarNo ratings yet

- 5SDocument56 pages5SInderpreet Singh AhujaNo ratings yet

- 5S and Workplace Productivity CLADocument48 pages5S and Workplace Productivity CLASteben MeuerteNo ratings yet

- 5S TrainingDocument32 pages5S TrainingQuest Certification B.KarthikeyanNo ratings yet

- Category Criteria Audit Period Scoring System: PLS Office 5S + Safety Audit Form - DraftDocument109 pagesCategory Criteria Audit Period Scoring System: PLS Office 5S + Safety Audit Form - DraftblitzkrigNo ratings yet

- 5S ManualDocument23 pages5S ManualBittuNo ratings yet

- What Is 5S?Document37 pagesWhat Is 5S?wferry27No ratings yet

- Chapter 5 Good HousekeepingDocument29 pagesChapter 5 Good HousekeepingOmar KatogNo ratings yet

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Document44 pagesSort Set-In-Order Shine Standardize Sustain: What Is 5-S?Angel David ChavezNo ratings yet

- S5 - Sustain: 5S Housekeeping Score SheetDocument1 pageS5 - Sustain: 5S Housekeeping Score SheetRama PrasetiaNo ratings yet

- About 5 SDocument9 pagesAbout 5 SKharolina BautistaNo ratings yet

- 5S ChecklistsDocument5 pages5S ChecklistsRheneir MoraNo ratings yet

- Reported By: Ms. Laarni P. LacandazoDocument36 pagesReported By: Ms. Laarni P. Lacandazolpl_0124No ratings yet

- Presentation 6 S STARTER TrainingDocument96 pagesPresentation 6 S STARTER Trainingm_ramas2001No ratings yet

- Module 5 - TQMDocument8 pagesModule 5 - TQMRevenlie GalapinNo ratings yet

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- 5s Step by Step GuideDocument10 pages5s Step by Step GuideKalkidan MekuriyaNo ratings yet

- LESSON 2-Occupational Health and SafetyDocument6 pagesLESSON 2-Occupational Health and Safetymelanielampera17No ratings yet

- 5SSSSSDocument19 pages5SSSSSHoàng Thị NguyênNo ratings yet

- 5'S ManualDocument44 pages5'S ManualSayan KonarNo ratings yet

- Stangerweb 5S Audit QuestionnaireDocument4 pagesStangerweb 5S Audit QuestionnaireambicaNo ratings yet

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Document40 pagesSort Set-In-Order Shine Standardize Sustain: What Is 5-S?blitzkrigNo ratings yet

- 5-S Handbook For Operations Depot 105/NBE-AM: TNT Express Germany Road Hub and Depot NürnbergDocument24 pages5-S Handbook For Operations Depot 105/NBE-AM: TNT Express Germany Road Hub and Depot NürnbergthomasarnosanderNo ratings yet

- 5s ReportDocument15 pages5s ReportAkash KarbotkarNo ratings yet

- 5s in Simba Apparels KenyaDocument19 pages5s in Simba Apparels KenyaPrerna Khatri100% (1)

- What Are The Five SDocument4 pagesWhat Are The Five Ssaman2580No ratings yet

- Assignment TQM 4Document5 pagesAssignment TQM 4Aiswarya ASNo ratings yet

- Assignment On Achieving Quality With 5 S AQM M.F.Tech - II SemDocument26 pagesAssignment On Achieving Quality With 5 S AQM M.F.Tech - II SempetcutpaulNo ratings yet

- Five SDocument41 pagesFive Srolly curiaNo ratings yet

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Document43 pagesSort Set-In-Order Shine Standardize Sustain: What Is 5-S?Navnath TamhaneNo ratings yet

- World Class Manufacturing PracticesDocument5 pagesWorld Class Manufacturing PracticesSumit_Raj_Patn_8373No ratings yet

- 5s Audit Check SheetDocument4 pages5s Audit Check SheetLAI WEI SINGNo ratings yet

- Module For Operations Management and TQM Part 5Document7 pagesModule For Operations Management and TQM Part 5Karyll JustoNo ratings yet

- 5SDocument12 pages5SJanzen BascoNo ratings yet

- Module 4 - Housekeeping (Occupational Safety)Document20 pagesModule 4 - Housekeeping (Occupational Safety)Sam100% (1)

- 5s ShortDocument24 pages5s ShortSMAKNo ratings yet

- Office 5s ChecklistDocument109 pagesOffice 5s ChecklistSercan Sülün100% (1)

- Five S Program: Sort (Clean Up)Document3 pagesFive S Program: Sort (Clean Up)Gina GuillénNo ratings yet

- Office 5S ChecklistDocument15 pagesOffice 5S ChecklisttahirNo ratings yet

- Introduction To "5S"..Document23 pagesIntroduction To "5S"..Rahul SharmaNo ratings yet

- 5S Audit ReportDocument8 pages5S Audit Reportmananshah89No ratings yet

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- Sticky Solutions: 99 Clever Tricks with Sticky Notes: 99 TricksFrom EverandSticky Solutions: 99 Clever Tricks with Sticky Notes: 99 TricksNo ratings yet

- Becoming Lean: Practical Steps to Build CompetitivenessFrom EverandBecoming Lean: Practical Steps to Build CompetitivenessRating: 5 out of 5 stars5/5 (1)