Professional Documents

Culture Documents

ZSS & LT

ZSS & LT

Uploaded by

kalimsail840 ratings0% found this document useful (0 votes)

0 views12 pagesZSS & LT of barrel reclaimers

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentZSS & LT of barrel reclaimers

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

0 views12 pagesZSS & LT

ZSS & LT

Uploaded by

kalimsail84ZSS & LT of barrel reclaimers

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 12

Knowledge sharing Session

• Today’s topic

1. Zero Speed Switch and it working

2. Long Travel (LT) mechanism of Barrel

Reclaimer.

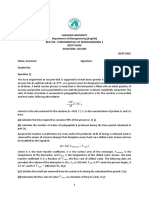

ZERO SPEED SWITCH (ZSS)

1. What is ZSS ?

2. Why it is used.?

3. Where it is used?

4. How it works ?

5. Points to remember while changing ZSS

controllers.

• ZSS is an electronic switch which gives running status

of an equipment.

• It is used to know the running status of driven

equipments which is mechanically coupled/interlinked

with the electrical drive.

It averts the major breakdown.

• In RMHP ZSS is used to know the running status of

1. Conveyors and

2. Crusher.

3. Screens

• The working principle of the ZSS is that,

It measure the speed of rotating equipments

by counting the no. of pulse with the help of

proxy.

• The proxy is connected to the controller by three

wires +, - and o/p.(RBG)

• When striker pass across the face of the probe,

the frontally radiated electromagnetic field of the

probe is damped which is converted to a

corresponding output pulse.

• And this pulse is converted to rotation per minute.

• No. of striker = No. of pulse = k x No. of

revolution counted.

ZSS Controller

Supply Voltage: 110/240 V , 50 Hz

1. Speed Setting range: dip switch given

for high and low range rpm setting.

2. Initial time delay knob

3. Nuisance time delay knob

4. Speed setting knob

5. Terminals for proxy connections

6. Terminals for power supply and

feedback NO/NC contacts.

ZSS Controller

Supply Voltage: 110/240 V , 50 Hz

1. Speed Setting range: 10 to 100 rpm

2. Range Calibration for 1 imp/revolution

3. Contact set to actuate at …..

4. Initial time delay knob

5. Nuisance time delay knob

6. Speed setting

7. Terminals for proxy connections

8. Terminals for power supply and

feedback NO/NC contacts.

Scheme of ZSS connection

1. Power supply to the controller from MCC

panel.

2. Connection of controller with Proxy.

3. NO/NC Contact interlock with the feeder.

• After replacement of controller, following points must be

taken care.

1. ITD must be kept below 5 sec, it may be set on minimum

i.e. zero if there is a initial time delay is considered in PLC

programming.

2. NTD must be set at 5-6 sec.

3. Speed setting must be done as per required speed.

Generally it should be kept between 3-4.

LT Mechanism of Barrel Reclimer.

LT Mechanism of Barrel Reclimer.

Slow LT

motor Slow LT gear

Magnetic Fast LT Fast LT

1.1KW, Box 101:1 Travel

Clutch, 90V motor 15 gear box

VFD run DC Wheel of

KW, DOL 63:1

machine

run

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Fig 2 - Brushless DC Motor Driver - EFY June 14Document1 pageFig 2 - Brushless DC Motor Driver - EFY June 14bahriun syahriNo ratings yet

- Auma India MovDocument28 pagesAuma India Movdk.verma100% (1)

- Bistable Multivibrator PDFDocument11 pagesBistable Multivibrator PDFYasir AliNo ratings yet

- Field Failure Out of StepDocument5 pagesField Failure Out of StepHéctor IbáñezNo ratings yet

- DC Motor ChopperDocument7 pagesDC Motor ChopperRoberto MartinezNo ratings yet

- AUTO CONTROLLER FOR PETROL (Revised)Document25 pagesAUTO CONTROLLER FOR PETROL (Revised)Hamed RazaNo ratings yet

- CD4060 Timer Circuit 1 Minute To 2 HoursDocument9 pagesCD4060 Timer Circuit 1 Minute To 2 HoursBabu Variath100% (1)

- HCF MDocument2 pagesHCF MboansahNo ratings yet

- Power Electronics Lab Simulation Project ReportDocument5 pagesPower Electronics Lab Simulation Project ReportMaha RaufNo ratings yet

- Automatic Fan Speed ControlDocument11 pagesAutomatic Fan Speed ControlAbhilash Redefining LoveNo ratings yet

- PS Lab ManualDocument49 pagesPS Lab Manual18-206 Ajay KumarNo ratings yet

- DC Motor Speed Controller Using IC 555 TimerDocument8 pagesDC Motor Speed Controller Using IC 555 Timerfarazpayoneer21No ratings yet

- To Study The Operation of A Instantaneous Over Current (IDMT Relay)Document8 pagesTo Study The Operation of A Instantaneous Over Current (IDMT Relay)Abhishek HotaNo ratings yet

- Electronics Washing Machine ControlDocument4 pagesElectronics Washing Machine ControlMohd ShukriNo ratings yet

- 1 Design A Protection System Using IDMT Relay To Protect System For Given Fault Currents & Plot The Operating Time Characteristics of The Relay UsedDocument6 pages1 Design A Protection System Using IDMT Relay To Protect System For Given Fault Currents & Plot The Operating Time Characteristics of The Relay UsedMR. SUSHIL BARAPATRENo ratings yet

- Induction Motor GK DubeyDocument13 pagesInduction Motor GK Dubeysakshamnegi40069No ratings yet

- Project ReportDocument14 pagesProject ReportNoah100% (7)

- Lab Manual Switchgear and Protection SapDocument46 pagesLab Manual Switchgear and Protection SapYash MaheshwariNo ratings yet

- PCB Project DetailsDocument4 pagesPCB Project DetailsmohanNo ratings yet

- Circuit Stepper Motor DriverDocument17 pagesCircuit Stepper Motor DriverkalpicoNo ratings yet

- Gate Driver Circuit For Three Phase InverterDocument13 pagesGate Driver Circuit For Three Phase InverterMarc TcheukabaNo ratings yet

- Diy K166Document3 pagesDiy K166Danny DurhamNo ratings yet

- Single Phase (Full Converter) DriveDocument3 pagesSingle Phase (Full Converter) DriveaskmeyrmailNo ratings yet

- Type 2 Co-Ordination Selection ChartsDocument48 pagesType 2 Co-Ordination Selection ChartsShashank GuptaNo ratings yet

- Motor Control: Instruction ManualDocument12 pagesMotor Control: Instruction ManualRICHIHOTS2No ratings yet

- Name: Faizan Bashir Reg No: F20604044 Submitted To: Sir Abdul Qadeer Date: 26/2/2023Document16 pagesName: Faizan Bashir Reg No: F20604044 Submitted To: Sir Abdul Qadeer Date: 26/2/2023safiullahadam353No ratings yet

- Home Circuits Other: SchematicDocument6 pagesHome Circuits Other: SchematicGrafo Bogdanov Novi SadNo ratings yet

- Electrical Drives (ARG)Document24 pagesElectrical Drives (ARG)alu bhindiNo ratings yet

- DeviceCraftDCmotorController 1015BDocument24 pagesDeviceCraftDCmotorController 1015BbetortitaNo ratings yet

- The 8051 Microcontroller and Embedded Systems: Motor Control: Relay, PWM, DC and Stepper MotorsDocument51 pagesThe 8051 Microcontroller and Embedded Systems: Motor Control: Relay, PWM, DC and Stepper MotorsAmAnDeepSingh100% (1)

- DC Motor Speed ControllerDocument22 pagesDC Motor Speed ControllerShafqt MbrkNo ratings yet

- HCF TDocument3 pagesHCF TJoebenson JjNo ratings yet

- Pub111 101 00 0720Document4 pagesPub111 101 00 0720vdphong2012No ratings yet

- Mod 2Document99 pagesMod 2SREEHARI V ANo ratings yet

- Introduction To Power SwitchesDocument33 pagesIntroduction To Power SwitchesjjaazzmmNo ratings yet

- Unit-6: Over Current ProtectionDocument52 pagesUnit-6: Over Current ProtectionREDAPPLE MEDIANo ratings yet

- MICROCONTROLLER-based DC Motor Speed ControllerDocument8 pagesMICROCONTROLLER-based DC Motor Speed Controllerranjithsim100% (1)

- Diy Kit 187: Stepper Motor Chopper DriverDocument4 pagesDiy Kit 187: Stepper Motor Chopper DriverNirav ChauhanNo ratings yet

- UtbsDocument41 pagesUtbsGaurav ChauhaanNo ratings yet

- Lect - 39 - 40 - Power Electronic Control of IM MotorsDocument18 pagesLect - 39 - 40 - Power Electronic Control of IM MotorsVishal MeghwarNo ratings yet

- Applied Electricity - Laboratory Reports 1Document12 pagesApplied Electricity - Laboratory Reports 1Pradeep JayasingheNo ratings yet

- Another Interesting Circuit From Burt Design PadDocument13 pagesAnother Interesting Circuit From Burt Design PadmoisesHolaNo ratings yet

- Chapter 5 Stepper MOTOR PracticalDocument16 pagesChapter 5 Stepper MOTOR PracticalmfmprofNo ratings yet

- Power Semiconductor DevicesDocument31 pagesPower Semiconductor DevicesLai Yon Peng50% (2)

- Softstart Digistart D3 Slip Ring Motor Control Application NoteDocument3 pagesSoftstart Digistart D3 Slip Ring Motor Control Application NoteIsaac AwudiNo ratings yet

- EG1000Document12 pagesEG1000alizanelectronicNo ratings yet

- D Escriptio S FeatureDocument16 pagesD Escriptio S FeatureSanjyNo ratings yet

- Components Side PCBDocument1 pageComponents Side PCBsohail nasirNo ratings yet

- Making Your Oscillator Work: Author: Brett Duane Microchip Technology IncDocument8 pagesMaking Your Oscillator Work: Author: Brett Duane Microchip Technology IncCícero Domingos JuniorNo ratings yet

- Microcontroller Based Speed Cntrol SystemDocument3 pagesMicrocontroller Based Speed Cntrol Systemvinovictory8571No ratings yet

- Current Control in Stepper MotorsDocument2 pagesCurrent Control in Stepper MotorsRoy FUNo ratings yet

- KA KR Motor Driver ManualDocument33 pagesKA KR Motor Driver Manualalexandr.vl.smk2No ratings yet

- of BLDCDocument45 pagesof BLDCsmhbNo ratings yet

- Sy1 Paralleling Unit PT Sinar Elektrindo PerkasaDocument7 pagesSy1 Paralleling Unit PT Sinar Elektrindo PerkasaAshraf IrfanNo ratings yet

- Auxiliary TransformerDocument22 pagesAuxiliary TransformerعليفاضلNo ratings yet

- Electrical Power-2 Lab ManualDocument6 pagesElectrical Power-2 Lab ManualAditya SanjeevNo ratings yet

- Automatic Restart of Essential Motors Using Micro Processor Based RelaysDocument21 pagesAutomatic Restart of Essential Motors Using Micro Processor Based RelaysJasa R ChoudharyNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Transactions Apparatus Systems, Vol - PAS-98, No.1: 97 Ieee Power and Jan/Feb 1979Document13 pagesTransactions Apparatus Systems, Vol - PAS-98, No.1: 97 Ieee Power and Jan/Feb 1979awolNo ratings yet

- Pile Load Test PDFDocument11 pagesPile Load Test PDFAjit P. SinghNo ratings yet

- Final Thesis VdPoll TU DELFTDocument55 pagesFinal Thesis VdPoll TU DELFTKarun NooneyNo ratings yet

- We Are Young Chords-FunDocument11 pagesWe Are Young Chords-FunDimas NaufalNo ratings yet

- Lubrication SystemDocument43 pagesLubrication Systemkebaman1986No ratings yet

- 2 1 Fg8jglt Eep Final (PM)Document1 page2 1 Fg8jglt Eep Final (PM)hyde2520015754No ratings yet

- 0510 w19 QP 22 PDFDocument16 pages0510 w19 QP 22 PDFAxel GanzaNo ratings yet

- AC Generator TheroryDocument11 pagesAC Generator TheroryM Kumar MarimuthuNo ratings yet

- To Calculate Monetary Saving by Changing Ex-Works Vendors From OM Logistics To Free Delivery Through Alternate TransporterDocument53 pagesTo Calculate Monetary Saving by Changing Ex-Works Vendors From OM Logistics To Free Delivery Through Alternate TransporterpeednaskNo ratings yet

- Sistem Thinking Dan Analisa Pengambilan KeputusanDocument47 pagesSistem Thinking Dan Analisa Pengambilan KeputusanyudiferiandiNo ratings yet

- Chapter 9-SPUR GEARS AND GEAR TRAINSDocument64 pagesChapter 9-SPUR GEARS AND GEAR TRAINSMohammed Al-OdatNo ratings yet

- Theo Wanne Tip Opening Chart TENORDocument1 pageTheo Wanne Tip Opening Chart TENORIsrael BandonillNo ratings yet

- JMA-7100 Instruction ManualDocument560 pagesJMA-7100 Instruction ManualViliame D RoqicaNo ratings yet

- Product CatalogDocument30 pagesProduct CatalogVeri Ambar SariNo ratings yet

- Steam Tracing SpecificationDocument14 pagesSteam Tracing SpecificationPankaj SahuNo ratings yet

- Achasta Bear Paw RidgeDocument1 pageAchasta Bear Paw RidgeC Bombin'No ratings yet

- ENGLISHDocument4 pagesENGLISHALLISONNo ratings yet

- RB Cba Executive Summary 0405Document24 pagesRB Cba Executive Summary 0405pepegrillo891No ratings yet

- Weatherby Vanguard Bolt Action RifleDocument22 pagesWeatherby Vanguard Bolt Action RifleJon MorenoNo ratings yet

- VAMP 125: Unit For Flexible Arc Flash ProtectionDocument12 pagesVAMP 125: Unit For Flexible Arc Flash Protectionuday chaurasiaNo ratings yet

- Tabatana 2023 ReportDocument15 pagesTabatana 2023 ReportKudakwashe Pride ChirendaNo ratings yet

- Polaris Ranger ManualDocument110 pagesPolaris Ranger ManualdarinNo ratings yet

- Maths (Standard) Class - X - SET-1 (English Version)Document7 pagesMaths (Standard) Class - X - SET-1 (English Version)shanmugan rajNo ratings yet

- DT KCDocument10 pagesDT KCbettieboomNo ratings yet

- 2-1 Basic CT EquipmentDocument35 pages2-1 Basic CT EquipmentAnthony LakpahNo ratings yet

- LeeBoy Tack Tank Manual 8 21 06 PDFDocument40 pagesLeeBoy Tack Tank Manual 8 21 06 PDFLuis Miguel Mamani CastroNo ratings yet

- 8.protocols For Collecting EvidenceDocument21 pages8.protocols For Collecting EvidenceMugilan KrishnamurthyNo ratings yet

- Governing System of 210mw KwuDocument21 pagesGoverning System of 210mw KwuNitesh Rasekar100% (5)

- Module 4 Family and Consumer Life Skills 5Document10 pagesModule 4 Family and Consumer Life Skills 5PAGHASIAN, RENAROSE JOYNo ratings yet

- III Eee I Sem Cs Lab Manual (Ee332) - 1Document51 pagesIII Eee I Sem Cs Lab Manual (Ee332) - 1Syed Salman AhmadNo ratings yet