Professional Documents

Culture Documents

OPR Front Bumper Assy - Problem Pickup - 06122023

OPR Front Bumper Assy - Problem Pickup - 06122023

Uploaded by

Hafizuddin SuhaimanCopyright:

Available Formats

You might also like

- CQI-11 Plating System AssessmentDocument31 pagesCQI-11 Plating System AssessmentKULDEEP THAKUR100% (1)

- Aurttk102 (Wa)Document28 pagesAurttk102 (Wa)ARSHAD TURINo ratings yet

- Admin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Document3 pagesAdmin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Saifulazreen Mahyan100% (1)

- Employee Post Training Evaluation FormDocument3 pagesEmployee Post Training Evaluation FormD Tech Dental Technologies100% (2)

- Process Industry PracticeDocument12 pagesProcess Industry PracticeRonald George100% (1)

- ISTQB Certified Tester Foundation Level Practice Exam QuestionsFrom EverandISTQB Certified Tester Foundation Level Practice Exam QuestionsRating: 5 out of 5 stars5/5 (1)

- Corrective Action Form PDFDocument1 pageCorrective Action Form PDFchahiNo ratings yet

- Coating System Assessment CQI-12Document40 pagesCoating System Assessment CQI-12dyolotzin100% (1)

- Layered Process Audit ChecksheetDocument7 pagesLayered Process Audit Checksheetalliceyew100% (3)

- Water Cycle Test SchoologyDocument5 pagesWater Cycle Test Schoologyapi-241192726No ratings yet

- FM - 12 Corrective Action RequestDocument1 pageFM - 12 Corrective Action RequestBleep NewsNo ratings yet

- Process Observation Tool: Quality FormDocument2 pagesProcess Observation Tool: Quality FormAroma Eyre100% (3)

- 8D Format Updated r1Document4 pages8D Format Updated r1புதுகை பாலாNo ratings yet

- 1.b Hasil Surveillance AuditDocument12 pages1.b Hasil Surveillance AuditFajar Ismanto Part IINo ratings yet

- Process Observation ToolDocument2 pagesProcess Observation ToolNestor CapinaNo ratings yet

- SOX Deficiencies TraiingDocument49 pagesSOX Deficiencies TraiingSridhair IyengarNo ratings yet

- Scan 20 Jul 2023Document1 pageScan 20 Jul 2023Hytham ShaerNo ratings yet

- Process Observation Tool PDF FreeDocument2 pagesProcess Observation Tool PDF FreeChristopher E. ZernaNo ratings yet

- Mareaux2 Lo 2.5 We 2.3 SemiDocument5 pagesMareaux2 Lo 2.5 We 2.3 SemiKahlil Kaimo MagsinoNo ratings yet

- QA-SQA-003 Supplier Quality System Audit CAPA by SupplierDocument11 pagesQA-SQA-003 Supplier Quality System Audit CAPA by SupplierAbhishek AllenNo ratings yet

- JV-P08 Corrective Action (OK)Document41 pagesJV-P08 Corrective Action (OK)BÍCH NGUYỄNNo ratings yet

- Candidate InformationDocument7 pagesCandidate InformationMarius BuysNo ratings yet

- X Photos: Problem DescriptionDocument3 pagesX Photos: Problem DescriptionproductionNo ratings yet

- Supplier Evaluation Instructions: Score DescriptionDocument8 pagesSupplier Evaluation Instructions: Score DescriptionCristina CoceasuNo ratings yet

- Essae 8.03.23Document4 pagesEssae 8.03.23Parthiban DNo ratings yet

- Safer by Association 2dec22Document48 pagesSafer by Association 2dec22mohamed Abo-EwishaNo ratings yet

- Management Review TemplateDocument4 pagesManagement Review TemplaterhydelNo ratings yet

- Vendor Assessment - Self AssessmentDocument10 pagesVendor Assessment - Self Assessmentjennice18No ratings yet

- Process Audit VDA-6 3-2010 - enDocument40 pagesProcess Audit VDA-6 3-2010 - enRohini GadhaweNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Bsci CertificateDocument18 pagesBsci CertificateraihanNo ratings yet

- IQWQ-CE1091-VPNDT-00-2564 - A PMI ProcedureDocument5 pagesIQWQ-CE1091-VPNDT-00-2564 - A PMI Procedurejacksonbello34No ratings yet

- SOP-QA-013-00-corrective and Preventive ActionDocument10 pagesSOP-QA-013-00-corrective and Preventive ActionNgoc Sang HuynhNo ratings yet

- Corrective Action FormDocument1 pageCorrective Action FormAmine ChahiNo ratings yet

- QMS IA Report - NRL C1C2Document10 pagesQMS IA Report - NRL C1C2R Sahadeo ReddyNo ratings yet

- Bug Defect Triage ProcessDocument20 pagesBug Defect Triage Processraulnq50% (2)

- VDA 6.3 2010 - enDocument45 pagesVDA 6.3 2010 - enMahender KumarNo ratings yet

- KPS Belt Inspection A1-J07 W23-07-2018Document8 pagesKPS Belt Inspection A1-J07 W23-07-2018maherianto 29No ratings yet

- Pfmea: Why Use It? How To Do It?Document7 pagesPfmea: Why Use It? How To Do It?imNo ratings yet

- SADCAS AP 05 - Identification and Management of Nonconformities (Issue 4)Document7 pagesSADCAS AP 05 - Identification and Management of Nonconformities (Issue 4)vNo ratings yet

- Title: Standard Operating Procedure For Investigation Sop No Version No.: 02 Page No. 1 of 8 Effective Date: Review Date: 1.0 ObjectiveDocument7 pagesTitle: Standard Operating Procedure For Investigation Sop No Version No.: 02 Page No. 1 of 8 Effective Date: Review Date: 1.0 ObjectiveBRIJENDRA KUMAR SINGHNo ratings yet

- Safety Investigation ReportDocument8 pagesSafety Investigation Reportherik100% (1)

- TCM-F-IMS-014 NCR - Pama - PC - Cleaning-MeiDocument2 pagesTCM-F-IMS-014 NCR - Pama - PC - Cleaning-Meiwahyu nurcahyoNo ratings yet

- Api 1Document19 pagesApi 1Siddheshwarr JabagoudarNo ratings yet

- JV-P06 Internal Audit (OK)Document25 pagesJV-P06 Internal Audit (OK)BÍCH NGUYỄNNo ratings yet

- Aterial Review Board (MRB) Is Defined As The Formal Contractor Processes For MakingDocument3 pagesAterial Review Board (MRB) Is Defined As The Formal Contractor Processes For Makingsifiso nkabindeNo ratings yet

- Ramp Up Activity Plan For HPDCDocument1 pageRamp Up Activity Plan For HPDCArun Pratap Singh ChauhanNo ratings yet

- 830 V1a MQ00 00030Document1 page830 V1a MQ00 00030davidNo ratings yet

- Rig Pass Site Visit Form - Rev5Document10 pagesRig Pass Site Visit Form - Rev5omargarzajrNo ratings yet

- A00F204e Audit Report - Stage 1Document5 pagesA00F204e Audit Report - Stage 1Md sameerNo ratings yet

- Risk Assessment Format OCLDocument4 pagesRisk Assessment Format OCLThusithaNo ratings yet

- Corrective Action Form-qs-141ADocument1 pageCorrective Action Form-qs-141AGAURAV SHARMANo ratings yet

- Quality Education Management System: Procedures ManualDocument5 pagesQuality Education Management System: Procedures ManualGe Villaver-SalvaneNo ratings yet

- Oral Presentation (Develop A Risk Assessment Implementation Plan 06 Apr 2021)Document15 pagesOral Presentation (Develop A Risk Assessment Implementation Plan 06 Apr 2021)Quek Keng LengNo ratings yet

- Internal Audit Report For Physical Stock Verification and Related Controls of Finished Fabrics Godown Functions Unit # 5Document13 pagesInternal Audit Report For Physical Stock Verification and Related Controls of Finished Fabrics Godown Functions Unit # 5ARSALAN SATTARNo ratings yet

- Supplier Audit Report - Rapindo - 140223Document38 pagesSupplier Audit Report - Rapindo - 140223Riandi SaputraNo ratings yet

- Backhoe Operator AssessmentDocument27 pagesBackhoe Operator AssessmentGermain DgermainNo ratings yet

- BackupDocument8 pagesBackupRS MANIKANDANNo ratings yet

- TCM F Ims 014 NCR Pama PC Cleaning MeiDocument2 pagesTCM F Ims 014 NCR Pama PC Cleaning Meiwahyu nurcahyoNo ratings yet

- A3 LCI Blank TemplateDocument1 pageA3 LCI Blank TemplatePMO WORKNo ratings yet

- The Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsFrom EverandThe Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsNo ratings yet

- Jothi Raj Trading Company: Mahendra Pumps PVT LTD, Unit-IDocument51 pagesJothi Raj Trading Company: Mahendra Pumps PVT LTD, Unit-IkrixotNo ratings yet

- Material SpecificationsDocument27 pagesMaterial Specificationssat palNo ratings yet

- F5 2 TekananDocument176 pagesF5 2 TekananAZRI AZMI BIN ABD AZIZ MoeNo ratings yet

- SCADA PresentationDocument6 pagesSCADA PresentationGigih PramonoNo ratings yet

- Gin 2904Document12 pagesGin 2904Sen HuNo ratings yet

- Mochammad Rafli Rayhan Hidayat - SPWM BIPOLARDocument4 pagesMochammad Rafli Rayhan Hidayat - SPWM BIPOLARrafli rayhanNo ratings yet

- Maq Fall03 Strategicbudgetingcasestudy PDFDocument10 pagesMaq Fall03 Strategicbudgetingcasestudy PDFYana Aida FitriahNo ratings yet

- Medium Voltage AC Drives: ACS6000 Water Cooling Units 029, 052Document40 pagesMedium Voltage AC Drives: ACS6000 Water Cooling Units 029, 052Samuel MarpaungNo ratings yet

- FMA RegsDocument361 pagesFMA RegsJiong SoonNo ratings yet

- 25 Things Managers Should Know About FEA - Digital EngineeringDocument3 pages25 Things Managers Should Know About FEA - Digital Engineeringjanaaidaas1996No ratings yet

- Prextherm 107-470 (B)Document4 pagesPrextherm 107-470 (B)dragosm78No ratings yet

- 16 - E65 Automatic Trunk Lid LiftDocument9 pages16 - E65 Automatic Trunk Lid LiftKent Wai100% (1)

- BT Renewal ANNEXURE II & III of PR Division, Narayanpet Mandal 13.02.2022Document11 pagesBT Renewal ANNEXURE II & III of PR Division, Narayanpet Mandal 13.02.2022K KARTHIKNo ratings yet

- Arctic Cat Spring ChartDocument2 pagesArctic Cat Spring ChartRobert FenskeNo ratings yet

- 0100CT1501 Sec-05Document4 pages0100CT1501 Sec-05João Carlos AlmeidaNo ratings yet

- Battery Recycling and Reusing (Li Ion)Document5 pagesBattery Recycling and Reusing (Li Ion)jisha rkrishnan100% (1)

- CM Assignment Saurabh 162050011Document3 pagesCM Assignment Saurabh 162050011saurabmi2No ratings yet

- Shuqaiq Steam Power Plant: OwnerDocument262 pagesShuqaiq Steam Power Plant: OwnerAaqib MujtabaNo ratings yet

- Bede BD-5 - WikipediaDocument13 pagesBede BD-5 - WikipediaOzan Öztürk100% (1)

- 2.0 Intro To Hydraulics, Pneumatics & PLC's Notes PDFDocument22 pages2.0 Intro To Hydraulics, Pneumatics & PLC's Notes PDFDannyNo ratings yet

- 18-A-Anchor and CablesDocument2 pages18-A-Anchor and CablesRohit SinghNo ratings yet

- HAT400 V1.0 enDocument6 pagesHAT400 V1.0 enThao Nguyen XuanNo ratings yet

- MODULE 2 - Activity #18 Approximate Analysis of Rectangular Building FrameDocument4 pagesMODULE 2 - Activity #18 Approximate Analysis of Rectangular Building FrameKriselle DulayNo ratings yet

- ICM CH 6 Answers To Chapter ProblemsDocument2 pagesICM CH 6 Answers To Chapter ProblemsyawahabNo ratings yet

- Manual 1 Torres AmcotDocument3 pagesManual 1 Torres AmcotRobert HernandezNo ratings yet

- Doosan EXC QuickCoupler ENDocument2 pagesDoosan EXC QuickCoupler ENFelipe HernandezNo ratings yet

- BE IT Syllabus Sem-III (BIT MESRA)Document3 pagesBE IT Syllabus Sem-III (BIT MESRA)Anudeex ShettyNo ratings yet

OPR Front Bumper Assy - Problem Pickup - 06122023

OPR Front Bumper Assy - Problem Pickup - 06122023

Uploaded by

Hafizuddin SuhaimanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OPR Front Bumper Assy - Problem Pickup - 06122023

OPR Front Bumper Assy - Problem Pickup - 06122023

Uploaded by

Hafizuddin SuhaimanCopyright:

Available Formats

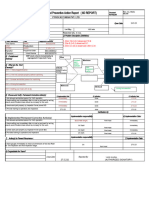

Issue No.

Status Model Problem type One Page Report Responsible

Other team

member

Other reviewer

member

Promotion

member

1 X70 MC2 PP-1 Date: 4/12/2023 Shafie Hafidz Farhan Alex

1. Detailed description of the problem 2. Cause investigation, analysis and progress

Part Name: Front Bumper Assy (PW937371) 5 Why analysis

Issue happened : 4 Dec 2023

Location : Proton T. Malim Occurrence

Problem : Front Bumper Upper have bulging W1 – Visible bulging (6 point) near on grille area

Qty defected: 1 unit W2 – Parameter not sufficient (holding pressure)

W3 – To reduce flashing.

W4 – Mold wear & tear.

W5 –Non - Detection

W1 – Not proper checking method & tools.

W2 – Less checking skills.

W3 – Not well train on standard inspection method

W4 – Defect not indicate in SIP.

Complete 5. (Lesson

3. Analytical conclusion 4. Measures and effects PIC Status

time Learnt)

1. 100% checking on inspection gate Interim Corrective Action:

1. 100% checking by visual. 27/11/23 Shafie / Ongoing

2. To checking all raw part condition Zaim

Permanent Corrective Action:

3. To adjust injection parameter by increase injection pressure. 7/12/23 Alex / Ongoing

Farhan

Issue No. Status Model Problem type One Page Report Responsible

Other team

member

Other reviewer

member

Promotion

member

3 X70 MC2 PP-1 Date: 4/12/2023 Shafie Hafidz Farhan Alex

1. Detailed description of the problem 2. Cause investigation, analysis and progress

Part Name: Front Bumper Assy (PW937371) 5 Why analysis

Issue happened : 4 Dec 2023

Location : Proton T. Malim Occurrence

Problem : Front Bumper Upper have line W1 – Visible line mark

mark on RH side only W2 – Core insert not level

Qty defected: 1 unit W3 – Mold insert un-balance during inject part

W4 – Need conduct mold service and insert refitting

Non - Detection

W1 – Visible line mark

W2 – Not proper checking method and less checking skills.

W3 – Not well train on standard inspection method

W4 – Defect not indicate on defect summary

Complete 5. (Lesson

3. Analytical conclusion 4. Measures and effects PIC Status

time Learnt)

1. 100% checking on inspection gate Interim Corrective Action:

1. 100% checking by visual. 27/11/23 Shafie / Ongoing

2. To checking all raw part condition Zaim

Permanent Corrective Action:

3. To conduct mold servicing and conduct latest trial. 7/12/23 Alex / Ongoing

Farhan

Issue No. Status Model Problem type One Page Report Responsible

Other team

member

Other reviewer

member

Promotion

member

4 X70 MC2 PP-1 Date: 4/12/2023 Shafie Hafidz Farhan Alex

1. Detailed description of the problem 2. Cause investigation, analysis and progress

Part Name: Front Bumper Assy (PW937371) 5 Why analysis

Issue happened : 4 Dec 2023

Location : Proton T. Malim Occurrence

Problem : Front Bumper Lower weld line W1 – Visible weld line on Front Bumper Lower

visible W2 – Material joining not sufficient

Qty defected: 1 unit W3 – Valve gate time delay

W4 – To reduce flashing.

Non - Detection

W1 – Visible weld line on Front Bumper Lower

W2 – Not proper checking method and less checking skills.

W3 – Not well train on standard inspection method

W4 – Defect not indicate on defect summary

Complete 5. (Lesson

3. Analytical conclusion 4. Measures and effects PIC Status

time Learnt)

1. 100% checking on inspection gate Interim Corrective Action:

1. 100% checking by visual. 30/11/23 Shafie / Ongoing

2. To checking all raw part condition Zaim

Permanent Corrective Action:

3. To conduct mold servicing and conduct latest trial. 1/12/23 Alex / Closed

Farhan

Issue No. Status Model Problem type One Page Report Responsible

Other team

member

Other reviewer

member

Promotion

member

10 X70 MC2 TT Event (GCPA) Date: 4/12/2023 Shafie Hafidz Farhan Alex

1. Detailed description of the problem 2. Cause investigation, analysis and progress

Part Name: Front Bumper Assy (PW937371) 5 Why analysis

Issue happened : 4 Dec 2023

Location : Proton T. Malim Occurrence

Problem : Front Bumper Assy have gap with W1 – Fr Bumper Assy have gap with Plate-Fr Licence Mounting

Plate-Fr Licence Mounting. W2 – Check gap fitting between bumper and Plate-Fr Licence Mounting

Qty defected: 1 unit W3 – Measurement single part PAS accuracy is 100% on CF

Non - Detection

W1 – Fr Bumper Assy have gap with Plate-Fr Licence Mounting

W2 – Detection after Fr Bumper installation on Body

W3 – No mention DTS spec on that area

Complete 5. (Lesson

3. Analytical conclusion 4. Measures and effects PIC Status

time Learnt)

1. To check PAS measurement every lot Interim Corrective Action:

injection. 1. Confirmation gap after assembly process 2/10/23 Proton / Closed

APP

Permanent Corrective Action:

You might also like

- CQI-11 Plating System AssessmentDocument31 pagesCQI-11 Plating System AssessmentKULDEEP THAKUR100% (1)

- Aurttk102 (Wa)Document28 pagesAurttk102 (Wa)ARSHAD TURINo ratings yet

- Admin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Document3 pagesAdmin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Saifulazreen Mahyan100% (1)

- Employee Post Training Evaluation FormDocument3 pagesEmployee Post Training Evaluation FormD Tech Dental Technologies100% (2)

- Process Industry PracticeDocument12 pagesProcess Industry PracticeRonald George100% (1)

- ISTQB Certified Tester Foundation Level Practice Exam QuestionsFrom EverandISTQB Certified Tester Foundation Level Practice Exam QuestionsRating: 5 out of 5 stars5/5 (1)

- Corrective Action Form PDFDocument1 pageCorrective Action Form PDFchahiNo ratings yet

- Coating System Assessment CQI-12Document40 pagesCoating System Assessment CQI-12dyolotzin100% (1)

- Layered Process Audit ChecksheetDocument7 pagesLayered Process Audit Checksheetalliceyew100% (3)

- Water Cycle Test SchoologyDocument5 pagesWater Cycle Test Schoologyapi-241192726No ratings yet

- FM - 12 Corrective Action RequestDocument1 pageFM - 12 Corrective Action RequestBleep NewsNo ratings yet

- Process Observation Tool: Quality FormDocument2 pagesProcess Observation Tool: Quality FormAroma Eyre100% (3)

- 8D Format Updated r1Document4 pages8D Format Updated r1புதுகை பாலாNo ratings yet

- 1.b Hasil Surveillance AuditDocument12 pages1.b Hasil Surveillance AuditFajar Ismanto Part IINo ratings yet

- Process Observation ToolDocument2 pagesProcess Observation ToolNestor CapinaNo ratings yet

- SOX Deficiencies TraiingDocument49 pagesSOX Deficiencies TraiingSridhair IyengarNo ratings yet

- Scan 20 Jul 2023Document1 pageScan 20 Jul 2023Hytham ShaerNo ratings yet

- Process Observation Tool PDF FreeDocument2 pagesProcess Observation Tool PDF FreeChristopher E. ZernaNo ratings yet

- Mareaux2 Lo 2.5 We 2.3 SemiDocument5 pagesMareaux2 Lo 2.5 We 2.3 SemiKahlil Kaimo MagsinoNo ratings yet

- QA-SQA-003 Supplier Quality System Audit CAPA by SupplierDocument11 pagesQA-SQA-003 Supplier Quality System Audit CAPA by SupplierAbhishek AllenNo ratings yet

- JV-P08 Corrective Action (OK)Document41 pagesJV-P08 Corrective Action (OK)BÍCH NGUYỄNNo ratings yet

- Candidate InformationDocument7 pagesCandidate InformationMarius BuysNo ratings yet

- X Photos: Problem DescriptionDocument3 pagesX Photos: Problem DescriptionproductionNo ratings yet

- Supplier Evaluation Instructions: Score DescriptionDocument8 pagesSupplier Evaluation Instructions: Score DescriptionCristina CoceasuNo ratings yet

- Essae 8.03.23Document4 pagesEssae 8.03.23Parthiban DNo ratings yet

- Safer by Association 2dec22Document48 pagesSafer by Association 2dec22mohamed Abo-EwishaNo ratings yet

- Management Review TemplateDocument4 pagesManagement Review TemplaterhydelNo ratings yet

- Vendor Assessment - Self AssessmentDocument10 pagesVendor Assessment - Self Assessmentjennice18No ratings yet

- Process Audit VDA-6 3-2010 - enDocument40 pagesProcess Audit VDA-6 3-2010 - enRohini GadhaweNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Bsci CertificateDocument18 pagesBsci CertificateraihanNo ratings yet

- IQWQ-CE1091-VPNDT-00-2564 - A PMI ProcedureDocument5 pagesIQWQ-CE1091-VPNDT-00-2564 - A PMI Procedurejacksonbello34No ratings yet

- SOP-QA-013-00-corrective and Preventive ActionDocument10 pagesSOP-QA-013-00-corrective and Preventive ActionNgoc Sang HuynhNo ratings yet

- Corrective Action FormDocument1 pageCorrective Action FormAmine ChahiNo ratings yet

- QMS IA Report - NRL C1C2Document10 pagesQMS IA Report - NRL C1C2R Sahadeo ReddyNo ratings yet

- Bug Defect Triage ProcessDocument20 pagesBug Defect Triage Processraulnq50% (2)

- VDA 6.3 2010 - enDocument45 pagesVDA 6.3 2010 - enMahender KumarNo ratings yet

- KPS Belt Inspection A1-J07 W23-07-2018Document8 pagesKPS Belt Inspection A1-J07 W23-07-2018maherianto 29No ratings yet

- Pfmea: Why Use It? How To Do It?Document7 pagesPfmea: Why Use It? How To Do It?imNo ratings yet

- SADCAS AP 05 - Identification and Management of Nonconformities (Issue 4)Document7 pagesSADCAS AP 05 - Identification and Management of Nonconformities (Issue 4)vNo ratings yet

- Title: Standard Operating Procedure For Investigation Sop No Version No.: 02 Page No. 1 of 8 Effective Date: Review Date: 1.0 ObjectiveDocument7 pagesTitle: Standard Operating Procedure For Investigation Sop No Version No.: 02 Page No. 1 of 8 Effective Date: Review Date: 1.0 ObjectiveBRIJENDRA KUMAR SINGHNo ratings yet

- Safety Investigation ReportDocument8 pagesSafety Investigation Reportherik100% (1)

- TCM-F-IMS-014 NCR - Pama - PC - Cleaning-MeiDocument2 pagesTCM-F-IMS-014 NCR - Pama - PC - Cleaning-Meiwahyu nurcahyoNo ratings yet

- Api 1Document19 pagesApi 1Siddheshwarr JabagoudarNo ratings yet

- JV-P06 Internal Audit (OK)Document25 pagesJV-P06 Internal Audit (OK)BÍCH NGUYỄNNo ratings yet

- Aterial Review Board (MRB) Is Defined As The Formal Contractor Processes For MakingDocument3 pagesAterial Review Board (MRB) Is Defined As The Formal Contractor Processes For Makingsifiso nkabindeNo ratings yet

- Ramp Up Activity Plan For HPDCDocument1 pageRamp Up Activity Plan For HPDCArun Pratap Singh ChauhanNo ratings yet

- 830 V1a MQ00 00030Document1 page830 V1a MQ00 00030davidNo ratings yet

- Rig Pass Site Visit Form - Rev5Document10 pagesRig Pass Site Visit Form - Rev5omargarzajrNo ratings yet

- A00F204e Audit Report - Stage 1Document5 pagesA00F204e Audit Report - Stage 1Md sameerNo ratings yet

- Risk Assessment Format OCLDocument4 pagesRisk Assessment Format OCLThusithaNo ratings yet

- Corrective Action Form-qs-141ADocument1 pageCorrective Action Form-qs-141AGAURAV SHARMANo ratings yet

- Quality Education Management System: Procedures ManualDocument5 pagesQuality Education Management System: Procedures ManualGe Villaver-SalvaneNo ratings yet

- Oral Presentation (Develop A Risk Assessment Implementation Plan 06 Apr 2021)Document15 pagesOral Presentation (Develop A Risk Assessment Implementation Plan 06 Apr 2021)Quek Keng LengNo ratings yet

- Internal Audit Report For Physical Stock Verification and Related Controls of Finished Fabrics Godown Functions Unit # 5Document13 pagesInternal Audit Report For Physical Stock Verification and Related Controls of Finished Fabrics Godown Functions Unit # 5ARSALAN SATTARNo ratings yet

- Supplier Audit Report - Rapindo - 140223Document38 pagesSupplier Audit Report - Rapindo - 140223Riandi SaputraNo ratings yet

- Backhoe Operator AssessmentDocument27 pagesBackhoe Operator AssessmentGermain DgermainNo ratings yet

- BackupDocument8 pagesBackupRS MANIKANDANNo ratings yet

- TCM F Ims 014 NCR Pama PC Cleaning MeiDocument2 pagesTCM F Ims 014 NCR Pama PC Cleaning Meiwahyu nurcahyoNo ratings yet

- A3 LCI Blank TemplateDocument1 pageA3 LCI Blank TemplatePMO WORKNo ratings yet

- The Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsFrom EverandThe Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsNo ratings yet

- Jothi Raj Trading Company: Mahendra Pumps PVT LTD, Unit-IDocument51 pagesJothi Raj Trading Company: Mahendra Pumps PVT LTD, Unit-IkrixotNo ratings yet

- Material SpecificationsDocument27 pagesMaterial Specificationssat palNo ratings yet

- F5 2 TekananDocument176 pagesF5 2 TekananAZRI AZMI BIN ABD AZIZ MoeNo ratings yet

- SCADA PresentationDocument6 pagesSCADA PresentationGigih PramonoNo ratings yet

- Gin 2904Document12 pagesGin 2904Sen HuNo ratings yet

- Mochammad Rafli Rayhan Hidayat - SPWM BIPOLARDocument4 pagesMochammad Rafli Rayhan Hidayat - SPWM BIPOLARrafli rayhanNo ratings yet

- Maq Fall03 Strategicbudgetingcasestudy PDFDocument10 pagesMaq Fall03 Strategicbudgetingcasestudy PDFYana Aida FitriahNo ratings yet

- Medium Voltage AC Drives: ACS6000 Water Cooling Units 029, 052Document40 pagesMedium Voltage AC Drives: ACS6000 Water Cooling Units 029, 052Samuel MarpaungNo ratings yet

- FMA RegsDocument361 pagesFMA RegsJiong SoonNo ratings yet

- 25 Things Managers Should Know About FEA - Digital EngineeringDocument3 pages25 Things Managers Should Know About FEA - Digital Engineeringjanaaidaas1996No ratings yet

- Prextherm 107-470 (B)Document4 pagesPrextherm 107-470 (B)dragosm78No ratings yet

- 16 - E65 Automatic Trunk Lid LiftDocument9 pages16 - E65 Automatic Trunk Lid LiftKent Wai100% (1)

- BT Renewal ANNEXURE II & III of PR Division, Narayanpet Mandal 13.02.2022Document11 pagesBT Renewal ANNEXURE II & III of PR Division, Narayanpet Mandal 13.02.2022K KARTHIKNo ratings yet

- Arctic Cat Spring ChartDocument2 pagesArctic Cat Spring ChartRobert FenskeNo ratings yet

- 0100CT1501 Sec-05Document4 pages0100CT1501 Sec-05João Carlos AlmeidaNo ratings yet

- Battery Recycling and Reusing (Li Ion)Document5 pagesBattery Recycling and Reusing (Li Ion)jisha rkrishnan100% (1)

- CM Assignment Saurabh 162050011Document3 pagesCM Assignment Saurabh 162050011saurabmi2No ratings yet

- Shuqaiq Steam Power Plant: OwnerDocument262 pagesShuqaiq Steam Power Plant: OwnerAaqib MujtabaNo ratings yet

- Bede BD-5 - WikipediaDocument13 pagesBede BD-5 - WikipediaOzan Öztürk100% (1)

- 2.0 Intro To Hydraulics, Pneumatics & PLC's Notes PDFDocument22 pages2.0 Intro To Hydraulics, Pneumatics & PLC's Notes PDFDannyNo ratings yet

- 18-A-Anchor and CablesDocument2 pages18-A-Anchor and CablesRohit SinghNo ratings yet

- HAT400 V1.0 enDocument6 pagesHAT400 V1.0 enThao Nguyen XuanNo ratings yet

- MODULE 2 - Activity #18 Approximate Analysis of Rectangular Building FrameDocument4 pagesMODULE 2 - Activity #18 Approximate Analysis of Rectangular Building FrameKriselle DulayNo ratings yet

- ICM CH 6 Answers To Chapter ProblemsDocument2 pagesICM CH 6 Answers To Chapter ProblemsyawahabNo ratings yet

- Manual 1 Torres AmcotDocument3 pagesManual 1 Torres AmcotRobert HernandezNo ratings yet

- Doosan EXC QuickCoupler ENDocument2 pagesDoosan EXC QuickCoupler ENFelipe HernandezNo ratings yet

- BE IT Syllabus Sem-III (BIT MESRA)Document3 pagesBE IT Syllabus Sem-III (BIT MESRA)Anudeex ShettyNo ratings yet