Professional Documents

Culture Documents

Value Engineering & Value Management: NTK Lokuliyana

Value Engineering & Value Management: NTK Lokuliyana

Uploaded by

LokuliyanaNOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Value Engineering & Value Management: NTK Lokuliyana

Value Engineering & Value Management: NTK Lokuliyana

Uploaded by

LokuliyanaNCopyright:

Available Formats

VALUE ENGINEERING & VALUE MANAGEMENT

by

NTK Lokuliyana

What is Value Engineering

Value Engineering (VE) is a management technique that seeks the best functional balance between Cost, Reliability and Performance of a product , project , process or service.

VE is generally conducted by an experience multidisciplinary team with varied specializations. The whole perspective of the VE team is to analyse the project from a functional/cost standpoint. Therein VE team would work out alternative design options that may improve the performance, build-ability and life-cycle

Value Engineering Team

Value Engineering team is generally independent of the design team, but its members must have experience in the particular field of the project in

Origin of Value Engineering

Value Engineering began during the World War II at General Electric.Co (GE) Value Engineering came into effect to maximize the limited labour, raw material and component parts otherwise being utilize for the war. Due to the scarcity of resource Lawrence Miles, Jerry Leftow and Harry Erlicher at GE, look for substitutes. They realize that substitution they came up with often reduced costs, improved product or both. What started as an accident of necessity was turned into a systematic process which they called Value Analysis.

Evolution of concept Value Engineering

Initially Miles and Co at GE observed that many of the substitute were providing equal or better performance at a lower costs; thus the first definition of Value Engineering became focused on the Cost ; i.e. costs validation exercises.

Initial definition of Value Engineering;

It

is an organized approach to providing the necessary functions at the lowest costs

Evolution of the concept of Value Engineering (Contd.)

However, Miles initial definition, i.e. value engineering to be a cost validation exercise completely ignored the quality and the end-use of the product/project. Value Engineering is not a cost cutting exercise by sacrificing the quality of the product of services.

Evolution of the concept Value Engineering (Contd.)

The original definition therefore transformed to as Value Engineering is; A organized approach for the identification and elimination of unnecessary costs. Unnecessary costs implies to cost which provides neither use , nor life, nor quality, nor appearance and nor customer features.

Value Engineering & Value Management

Value

Engineering and Value Management often means different things to different people.

Value Engineering & Value Management

Value Management (VM) Value Management can be defined as a structured process through which the various elements and functions of a project are critically analyzed to ensure maximum value for money.

Value Engineering & Value Management

Value Engineering (VE) Value Engineering can be defined as a externally facilitated process through which the owner/client can demonstrate that the overall design objectives of the project are being provided at a minimum costs whilst maintaining the stated quality.

Value Engineering & Value Management

What is the difference ? One of major difference between VM and VE is that VM considered from the strategic point of view whereas VE considered from a tactical point of view.

In simple terms VM address WHY ? And VE address HOW?

Why owner/client pursue on Value Engineering

The client could be concern of the escalation of the estimated cost for the project. The client could be concern due to the tenders received were in excess of the budget. The client may be loosing confidence in the design team and/or project. The client may require an independent audit of the project before it is submitted for approval. The client may seek to minimize the capital and/or operational costs and maximize profits The client may genuinely wish to pursue an innovative/better solution for his/her project.

Value Engineering Study (Contd.) Phase 2 Basic Job Plan

Information Phase Speculation Phase Judgment Phase Development Phase

Presentation Phase

Value Engineering Study (Contd.) Phase 2 Basic Job Plan (Contd.)

Information Phase Further familiarization of the project by the team; all team members participate in a function analysis of the project as a whole, and then of its component part, to determine the true needs of the project. Areas of high costs or low worth are also to be identified during this phase. Information phase of the Value Engineering Study is a never ending process as it keeps on adding as the study progress.

Value Engineering Study (Contd.) Phase 2 Basic Job Plan (Contd.)

Speculation Phase During this phase the VE team will list creative ideas generated from its review of the project with the aim of obtaining a large number of ideas through brainstorming.

Value Engineering Study (Contd.) Phase 2 Basic Job Plan (Contd.)

Judgment Phase During this phase VE team will analyze the creative ideas generated during the previous stage. Ideas found to be impractical and to be irrelevant, or not worthy of additional study shall be regarded. Ideas with the potential of cost saving or improvements to the project shall be identified for further development.

Value Engineering Study (Contd.) Phase 2 Basic Job Plan (Contd.)

Development Phase During this phase VE team shall prepare alternative designs with capital and/or life cycle cost comparison of original design and proposed alternatives. All recommendations are supplemented with written descriptions, sketches, basic concepts , technical information and cost summaries.

Value Engineering Study (Contd.) Phase 2 Basic Job Plan (Contd.)

Presentation Phase During this phase VE team shall present an oral summary of its finding to the owner and the designer, explaining the basic ideas of alternatives, its cost-saving implications and their attendant rationales.

Value Engineering Study (Contd.) Phase 3

Phase 3 The Post Workshop Phase In the Post Workshop Phase the VE team will prepare a report for the owner incorporating their findings discuss in previous phases. The owner and the designer shall then consider the VE recommendation , and jointly decide which recommendations have merit for implementation in the revised design.

Value Engineering Study (Contd.) Five Step of the Job plan

The five (5) steps of the job plan are shown in the diagram above. The significance of the arrows is that whilst a cascade system is used, with each phase flowing on from and using the output of the preceding phase, there is a frequent reversion to the previous phase.

Value Engineering What are the benefits

Solve immediate and high priority problems Establish low cost goals Reduce Time Reduce commercial risks

Identify and define stakeholders aims and objectives

Optimize the unit/component cost Produce unique solutions Increase the market potentials Improve communication

Help to increase cooperation between departments

Encourage fresh thinking Spread cost-consciousness Develop hidden abilities Help to provide better appreciation of the other mans job Alternative Perspective

Improve quality

Value Engineering What are the benefits - Some Facts

A recent study carried out in United States shown that typical VE study may realize saving of over 5% of the capital costs of the project and achieve a return of over ten dollars (US $ 10.00) per dollar (US$ 1.00) expended.

VE study costs are approximately 0.4 % of the total construction costs, which is relatively low compared to the potential benefit.

When to Apply Value Engineering

Value Engineering can take place at any stage of the Project. However, it is acknowledged that there is a greater Return of Investment (ROI) if VE is used at a very early stage of a project, as illustrated in the following figure. (See next slide). Ideally VE should be carried out even before allocating funds for the project.

When to Apply Value Engineering Pictorial Illustration

Value Engineering as per the Provision of FIDIC

Value Engineering as per the Provision of FIDIC Why Sub Cl. 13.2 in the Contract

For the Contractor profits are derived from the contract costs; therefore, reducing the costs will reduce the profits. Therefore, after the Contract was awarded there is little reason for the Contractor to reduce the acquisition or life cycle costs. Sub-Cl. 13.2 dramatically neutralize this advantage.

Quantity Surveyors role in Value Engineering

Following task undertaken by Quantity Surveying practitioners are deemed to be form part of Value Engineering;

Forecasting expenditure flow Cost planning and cost controlling

Advising on cost limits and preparing budgets

Advising on cash-flow forecasting Advising on life cycle costing Cost analysis

Cost benefit analysis

Estimating Evaluating alternative designs Undertaking feasibility studies

Investment appraisal

Value Engineering

Questions ?

You might also like

- Nicmar Assignment PGPPM Sode 21Document13 pagesNicmar Assignment PGPPM Sode 21abdulNo ratings yet

- CEILLI Sample Questions - Set 3 (ENG)Document11 pagesCEILLI Sample Questions - Set 3 (ENG)Raja Mohan83% (6)

- CVS Certification ManualDocument32 pagesCVS Certification Manual황상훈No ratings yet

- Use of Artificial Neural Network For Pre Design Cost Estimation of Building ProjectsDocument4 pagesUse of Artificial Neural Network For Pre Design Cost Estimation of Building ProjectsEditor IJRITCCNo ratings yet

- Computer-Aided Project Organization & ManagementDocument62 pagesComputer-Aided Project Organization & ManagementAref MalkawiNo ratings yet

- Coursework 1 - CPDocument15 pagesCoursework 1 - CPMufeez Lebbe0% (1)

- Assignment - Professional Commiunications and Negotiation Skills-1Document5 pagesAssignment - Professional Commiunications and Negotiation Skills-1LokuliyanaN33% (3)

- Project Cost Management PDFDocument60 pagesProject Cost Management PDFvikram12267% (3)

- Globalization Education Management Agendas IDocument350 pagesGlobalization Education Management Agendas IPopa EliNo ratings yet

- Bbs Curriculum Tribhuvan University PDFDocument21 pagesBbs Curriculum Tribhuvan University PDFSandeep BhandariNo ratings yet

- Value EnggDocument61 pagesValue Enggsandeep patelNo ratings yet

- Value Engineering: SAVE InternationalDocument7 pagesValue Engineering: SAVE InternationalSadaf NazNo ratings yet

- Chapter:-7 Value Engineering IntroductionDocument35 pagesChapter:-7 Value Engineering Introductionmannuvpatel100% (1)

- Basics of Value Engineering - ASPEDocument22 pagesBasics of Value Engineering - ASPErekcahz100% (1)

- Value Engineering: Submitted To: Engr. Babinizer MemoracionDocument28 pagesValue Engineering: Submitted To: Engr. Babinizer MemoracionTrizzhaynah AbejarNo ratings yet

- From Pmbok (Project Management Body of Knowledge) Guide: What Is Value Engineering?Document7 pagesFrom Pmbok (Project Management Body of Knowledge) Guide: What Is Value Engineering?marisevenNo ratings yet

- Term Paper - Value EngineeringDocument18 pagesTerm Paper - Value Engineeringanon_992107504No ratings yet

- Value AnalysisDocument6 pagesValue AnalysisLln PsgnNo ratings yet

- Value Engineering PDFDocument14 pagesValue Engineering PDFKennith Ng0% (1)

- Value Engineering-NotesDocument4 pagesValue Engineering-Notesrajeshsapkota123No ratings yet

- Lecture Notes - Value ManagementDocument9 pagesLecture Notes - Value ManagementsympathhiaNo ratings yet

- Value Engineering in Construction IndustryDocument4 pagesValue Engineering in Construction Industryz_artist95No ratings yet

- Value Methodology Glossary PDFDocument4 pagesValue Methodology Glossary PDFCalNo ratings yet

- How To Improve Site ConstructabilityDocument4 pagesHow To Improve Site ConstructabilitylizaNo ratings yet

- Building Economics Life Cycle Cost AnalysisDocument4 pagesBuilding Economics Life Cycle Cost AnalysisPrdeep SinghNo ratings yet

- Value Engineering & Value AnalysisDocument49 pagesValue Engineering & Value AnalysisFaran ShaikhNo ratings yet

- Improving Product Development With Value EngineeringDocument11 pagesImproving Product Development With Value EngineeringsnilkanthNo ratings yet

- A Critical Literature Review On Application of Value Engineering in Building Construction ProjectDocument4 pagesA Critical Literature Review On Application of Value Engineering in Building Construction ProjectjayNo ratings yet

- The Value Methodology Memory Jogger Errata Sheet Jan 2023 Zu37uiDocument1 pageThe Value Methodology Memory Jogger Errata Sheet Jan 2023 Zu37uisarantceNo ratings yet

- Fast Diagram PDFDocument16 pagesFast Diagram PDFROHIT SINGHNo ratings yet

- Life Cycle Cost AnalysisDocument36 pagesLife Cycle Cost AnalysisNIDHI JARIWALANo ratings yet

- Factors Influencing Delays and Cost Overruns On Construction Projects in NigeriaDocument107 pagesFactors Influencing Delays and Cost Overruns On Construction Projects in NigeriaNguenangNo ratings yet

- Gaja Puyal ListDocument9 pagesGaja Puyal ListVijayssc SivaNo ratings yet

- Unit 9 Measuring Estimating and Tendering Processes in Construction and The Built EnvironmentDocument15 pagesUnit 9 Measuring Estimating and Tendering Processes in Construction and The Built EnvironmentHafizah EzaniNo ratings yet

- Top 100 Quantity Surveying Interview Q&ADocument19 pagesTop 100 Quantity Surveying Interview Q&ABENFDIL MOHAMED YASSINENo ratings yet

- Perspective of Road Asset Management in Asian CountriesDocument26 pagesPerspective of Road Asset Management in Asian Countriesnamazu100% (1)

- Cesmm 3Document19 pagesCesmm 3Supun Viduranga67% (3)

- Pre Planning of Building ProjectsDocument32 pagesPre Planning of Building ProjectsTuấn Anh Nguyễn100% (1)

- Avoiding Cost Overruns in Construction PDocument11 pagesAvoiding Cost Overruns in Construction Pnasru hajiNo ratings yet

- Construction ContractDocument7 pagesConstruction Contracttesfu tadesseNo ratings yet

- Lean Technology and Waste Minimization in Construction Industry Using SPSSDocument11 pagesLean Technology and Waste Minimization in Construction Industry Using SPSSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Lesson 3 - Planning and Scheduling - Pert-CpmDocument65 pagesLesson 3 - Planning and Scheduling - Pert-CpmChrysler VergaraNo ratings yet

- Managing & Controlling Airport Construction Projects - Jan 2001Document10 pagesManaging & Controlling Airport Construction Projects - Jan 2001TATATAHERNo ratings yet

- Time Cost Quality in ConstructionDocument7 pagesTime Cost Quality in ConstructionPui MunNo ratings yet

- Cost Control and Tracking of A Building by Earned Value MethodDocument8 pagesCost Control and Tracking of A Building by Earned Value MethodAman ThakurNo ratings yet

- BIM NotesDocument3 pagesBIM Notesrameezut TauheedNo ratings yet

- Volume IV - Value Engineering: Project Development ManualDocument58 pagesVolume IV - Value Engineering: Project Development ManualspkumarthNo ratings yet

- Risk Management in Construction Projects - AbstractDocument1 pageRisk Management in Construction Projects - AbstractFrank Victor Mushi0% (1)

- 1.0 Introduction To Construction Management 1Document23 pages1.0 Introduction To Construction Management 1Rose Anne RamonNo ratings yet

- Past Paper Answers 2 CSDocument15 pagesPast Paper Answers 2 CSLokuliyanaNNo ratings yet

- Value Engineering NotesDocument39 pagesValue Engineering Notesashish kumarNo ratings yet

- Decision Tree For Road MaintenanceDocument11 pagesDecision Tree For Road Maintenancemarcos64No ratings yet

- Life Cycle CostingDocument15 pagesLife Cycle CostingShahnoor ShafiNo ratings yet

- Construction Reports (Appendices)Document21 pagesConstruction Reports (Appendices)Haneef MohamedNo ratings yet

- Pat 252: Construction Project Management: Ts. Mardhiah Farhana BT OmarDocument29 pagesPat 252: Construction Project Management: Ts. Mardhiah Farhana BT Omaradeliene 25No ratings yet

- 2 ValueenggDocument14 pages2 Valueenggalfred100% (1)

- CII Bench Marking & MetricsDocument53 pagesCII Bench Marking & MetricsjorgearangogNo ratings yet

- Qs ProjectDocument19 pagesQs ProjectMuha Mmed Jib RilNo ratings yet

- Life Cycle CostingDocument17 pagesLife Cycle CostinghumairadivaioleNo ratings yet

- Study of Factors Affecting Construction Cost Performance in Nigerian Construction Sites. Amusan.L.M E-Mail: Worldalternativeamusan@yahoo AbstractDocument18 pagesStudy of Factors Affecting Construction Cost Performance in Nigerian Construction Sites. Amusan.L.M E-Mail: Worldalternativeamusan@yahoo AbstractAfeez MayowaNo ratings yet

- 50 QS Interview Questions & AnswersDocument52 pages50 QS Interview Questions & AnswersJonas DizonNo ratings yet

- Pros Cons Handout Delivery SystemsDocument35 pagesPros Cons Handout Delivery SystemsRufus ChengNo ratings yet

- Interrelation Between TEVT and General EducationDocument9 pagesInterrelation Between TEVT and General EducationLokuliyanaNNo ratings yet

- CDC Members ET & ITDocument4 pagesCDC Members ET & ITLokuliyanaNNo ratings yet

- Minuets of The Second SCTVE MeetingDocument11 pagesMinuets of The Second SCTVE MeetingLokuliyanaNNo ratings yet

- MM MMDocument19 pagesMM MMjoseph_dadaNo ratings yet

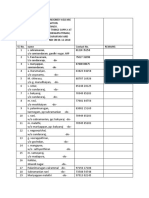

- Summary of BOQ: A PreliminariesDocument4 pagesSummary of BOQ: A PreliminariesLokuliyanaNNo ratings yet

- Risk Management - Insurances, Bonds and Collateral Warranties-1Document68 pagesRisk Management - Insurances, Bonds and Collateral Warranties-1LokuliyanaNNo ratings yet

- Curriculum Advisory Committees Engineering TechnologyDocument2 pagesCurriculum Advisory Committees Engineering TechnologyLokuliyanaNNo ratings yet

- Negligence Project Manager in Construction Industry English Literature EssayDocument21 pagesNegligence Project Manager in Construction Industry English Literature EssayLokuliyanaNNo ratings yet

- Criteria Comments Achievement (Y / N)Document7 pagesCriteria Comments Achievement (Y / N)LokuliyanaNNo ratings yet

- Criteria Comments Achievement (Y / N)Document7 pagesCriteria Comments Achievement (Y / N)LokuliyanaNNo ratings yet

- Department of Technology Education Faculty of Science and TechnologyDocument2 pagesDepartment of Technology Education Faculty of Science and TechnologyLokuliyanaNNo ratings yet

- Building ProcurementDocument27 pagesBuilding ProcurementLokuliyanaNNo ratings yet

- Ocupational HealthDocument19 pagesOcupational HealthLokuliyanaNNo ratings yet

- Role of The Quantity SurveyorDocument13 pagesRole of The Quantity SurveyorLokuliyanaNNo ratings yet

- Contract CloseoutDocument12 pagesContract CloseoutLokuliyanaNNo ratings yet

- Contract Close Out Discussion Questions 2 Complete AnswerDocument6 pagesContract Close Out Discussion Questions 2 Complete AnswerLokuliyanaNNo ratings yet

- Construction EngineeringDocument22 pagesConstruction EngineeringLokuliyanaNNo ratings yet

- JD Dpaf F THFDQ FSF FHD KHW WPL L Vupnghus FsDocument11 pagesJD Dpaf F THFDQ FSF FHD KHW WPL L Vupnghus FsLokuliyanaNNo ratings yet

- Construction TechnologyDocument15 pagesConstruction TechnologyLokuliyanaNNo ratings yet

- Best Practice Teachers ResourcesDocument7 pagesBest Practice Teachers Resourcesapi-243721743No ratings yet

- Tendering Code of Practice PDFDocument48 pagesTendering Code of Practice PDFkhajaimad100% (1)

- Loans & Advances - GTBankDocument2 pagesLoans & Advances - GTBankAdegboyega Moses SegunNo ratings yet

- MBA Chapter 1 Defining Marketing For The 21st Century Marketing Management (13th Edition)Document32 pagesMBA Chapter 1 Defining Marketing For The 21st Century Marketing Management (13th Edition)Ikramul HaqueNo ratings yet

- Lupient Leasing JudgmentDocument6 pagesLupient Leasing JudgmentghostgripNo ratings yet

- Developing Business Information Technology StrategiesDocument3 pagesDeveloping Business Information Technology StrategiesZohaib AhmedNo ratings yet

- Milan LabDocument8 pagesMilan LabhiprasoonNo ratings yet

- Pre-Merger Due Diligence:: Tata-JLR DealDocument12 pagesPre-Merger Due Diligence:: Tata-JLR DealStephen JohnsonNo ratings yet

- Assement Exam-Dysas 1st Quarter-P1Document5 pagesAssement Exam-Dysas 1st Quarter-P1JohnAllenMarillaNo ratings yet

- Summer Training ProjectDocument46 pagesSummer Training ProjectShah Zubi100% (1)

- CFO Edge Traditional Budgeting Vs Beyond BudgetingDocument3 pagesCFO Edge Traditional Budgeting Vs Beyond BudgetingSong SongNo ratings yet

- University of Poonch Rawalakot: Assignment No:01Document5 pagesUniversity of Poonch Rawalakot: Assignment No:01Aiman KhanNo ratings yet

- PolicySoftCopy 128978270Document2 pagesPolicySoftCopy 128978270amit malikNo ratings yet

- Lapran Keuangan Kso Per November 2021Document13 pagesLapran Keuangan Kso Per November 2021BekNo ratings yet

- FCUBS-FD01-01-01 Development Overview GuideDocument25 pagesFCUBS-FD01-01-01 Development Overview GuideParthuReddyNo ratings yet

- SAP FI Training MaterialDocument67 pagesSAP FI Training Materialamarnathreddyl50% (4)

- Apparel Quality ManagementDocument14 pagesApparel Quality ManagementPratik RajNo ratings yet

- Reddy Ice Disclosure StatementDocument757 pagesReddy Ice Disclosure Statementbankrupt0No ratings yet

- Chanel Inc. v. Chanel's Salon and Chanel Jones, 2:14-cv-00304.Document14 pagesChanel Inc. v. Chanel's Salon and Chanel Jones, 2:14-cv-00304.MAWLAW Marie-Andree WeissNo ratings yet

- An Over View of The Sainsburys Company Marketing EssayDocument17 pagesAn Over View of The Sainsburys Company Marketing EssayHND Assignment HelpNo ratings yet

- Anti-Child Labour: An Initiative Taken by N.G.O "Apne Sapne''Document5 pagesAnti-Child Labour: An Initiative Taken by N.G.O "Apne Sapne''VIMARSH SINGHNo ratings yet

- EasySteel - Steel Book 2012+calculations PDFDocument112 pagesEasySteel - Steel Book 2012+calculations PDFKen MugambiNo ratings yet

- Chap 014Document18 pagesChap 014Kuthubudeen T M0% (1)

- Foundations For Services MarketingDocument30 pagesFoundations For Services MarketingHussam Ali100% (1)

- ListDocument4 pagesListSplashy BabyNo ratings yet

- Norma S-311-P-18LDocument18 pagesNorma S-311-P-18LAugusto RadaelliNo ratings yet

- A Complex View of Industry 4.0, by Vasja Roblek, Maja Meško, and Alojz KrapežDocument11 pagesA Complex View of Industry 4.0, by Vasja Roblek, Maja Meško, and Alojz KrapežLeopoldo ArtilesNo ratings yet

- Belts Failure Book Final CE8149Document16 pagesBelts Failure Book Final CE8149vulpinorNo ratings yet